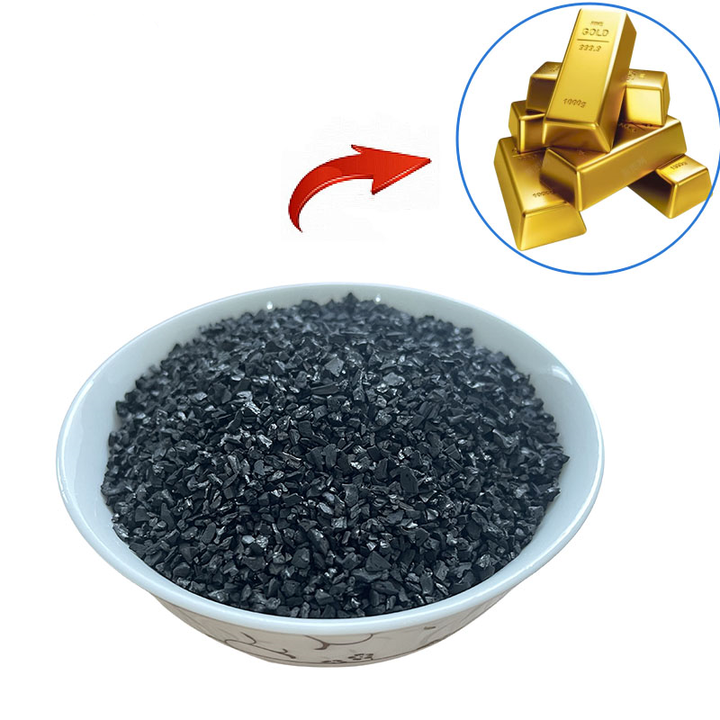

borax for gold refining

Borax for Gold Refining: A Safer and More Efficient Method

Introduction to Borax for Gold Refining

The use of borax for gold refining has gained popularity due to its efficiency and safety advantages over traditional refining methods. Borax, also known as sodium borate, is a naturally occurring mineral that has been used for centuries in various applications, including glassmaking and detergents. In recent years, it has become a preferred method for small-scale gold miners and refiners who seek an eco-friendly and cost-effective alternative to toxic chemicals like mercury and cyanide. The use of borax for gold refining is particularly beneficial for artisanal miners and those in developing regions.

How Borax Works in the Gold Refining Process

The primary function of borax in the gold refining process is to act as a flux, a substance that helps to separate gold from impurities during the smelting process. By lowering the melting point of gold and other materials, borax makes it easier to melt the ore and extract pure gold. This method is not only efficient but also eliminates the need for dangerous chemicals, reducing the environmental and health risks associated with traditional gold refining processes.

Borax as a Flux

Borax for gold refining is highly effective as a flux because it lowers the melting point of gold and other minerals. When gold-bearing ore is heated, borax reacts with metal oxides and other impurities, creating a molten mixture that can be easily separated from the gold. The lower melting point allows for faster processing and less energy consumption, making it an attractive option for small-scale refiners.

Removing Impurities

One of the key advantages of using borax for gold refining is its ability to remove impurities efficiently. Borax forms a glassy slag when it reacts with impurities, trapping them and leaving behind pure gold. This process results in high-purity gold with fewer contaminants compared to traditional refining methods. The use of borax also minimizes the need for further chemical treatments, simplifying the overall refining process.

The Process of Using Borax for Gold Refining

Refining gold with borax is relatively simple and can be done with basic equipment, making it accessible to small-scale and artisanal miners. The process involves crushing the gold-bearing ore, adding borax, and then heating the mixture until the gold separates from the impurities. Once the gold is extracted, it can be purified further if necessary, although the borax method already yields gold of a high purity.

Step-by-Step Process

The first step in using borax for gold refining is to crush the gold ore into a fine powder. This increases the surface area and allows the borax to work more effectively during the smelting process. Once crushed, the ore is mixed with borax and placed in a crucible or other heat-resistant container. The mixture is then heated with a torch or in a furnace until it reaches the melting point of gold.

As the mixture heats up, the borax melts and combines with the impurities in the ore, forming a liquid slag. The gold, being heavier than the slag, sinks to the bottom of the container, where it can be separated. After cooling, the slag is removed, and the pure gold can be collected and processed further if needed.

Advantages of the Borax Method

One of the main advantages of using borax for gold refining is its simplicity and low cost. The materials needed for the process are inexpensive and widely available, making it an ideal solution for small-scale miners. Additionally, the borax method does not require toxic chemicals, making it safer for workers and reducing the environmental impact of gold refining.

Environmental and Health Benefits of Borax for Gold Refining

The use of borax for gold refining offers significant environmental and health benefits, especially when compared to traditional methods that rely on mercury or cyanide. Mercury is commonly used in small-scale mining operations to amalgamate gold, but it poses severe health risks to miners and communities. Cyanide, while effective in larger-scale operations, is highly toxic and can cause serious environmental damage if not handled properly.

Eliminating Mercury

One of the most important benefits of using borax for gold refining is that it eliminates the need for mercury. Mercury exposure is linked to a range of health problems, including neurological damage and kidney failure. By switching to borax, small-scale miners can protect themselves and their communities from the harmful effects of mercury poisoning. The borax method also reduces the environmental contamination caused by mercury, which can persist in ecosystems for decades.

Reducing Toxic Waste

Borax for gold refining also helps to reduce the amount of toxic waste generated by gold refining operations. The borax method produces relatively little waste compared to cyanide or mercury-based methods, and the slag produced during the process can often be disposed of safely. This makes the borax method a more sustainable and environmentally friendly option for gold refining.

Applications of Borax for Gold Refining in Artisanal Mining

The use of borax for gold refining is particularly beneficial for artisanal miners, who often operate in remote areas with limited access to modern equipment and chemicals. The simplicity and affordability of the borax method make it an ideal solution for these miners, allowing them to extract gold efficiently without the need for expensive or dangerous chemicals. Many organizations and governments are promoting the borax method as a safer and more sustainable alternative to mercury-based mining practices.

Training and Education

To encourage the adoption of borax for gold refining, training and education programs are being implemented in many regions where artisanal mining is common. These programs teach miners how to use borax effectively and safely, helping to reduce the health risks and environmental impact associated with gold refining. As more miners adopt the borax method, it is expected to improve working conditions and promote more sustainable mining practices worldwide.

Borax for gold refining is an effective, affordable, and environmentally friendly method that offers significant advantages over traditional gold refining techniques. By using borax as a flux, refiners can achieve high-purity gold while reducing the need for harmful chemicals like mercury and cyanide. This method is particularly beneficial for small-scale and artisanal miners, providing a safer and more sustainable way to extract gold. As awareness of the borax method grows, it is likely to become an increasingly popular choice for gold refining around the world.