crucible for gold smelting

Crucible for Gold Smelting A Key Tool in Precious Metal Processing

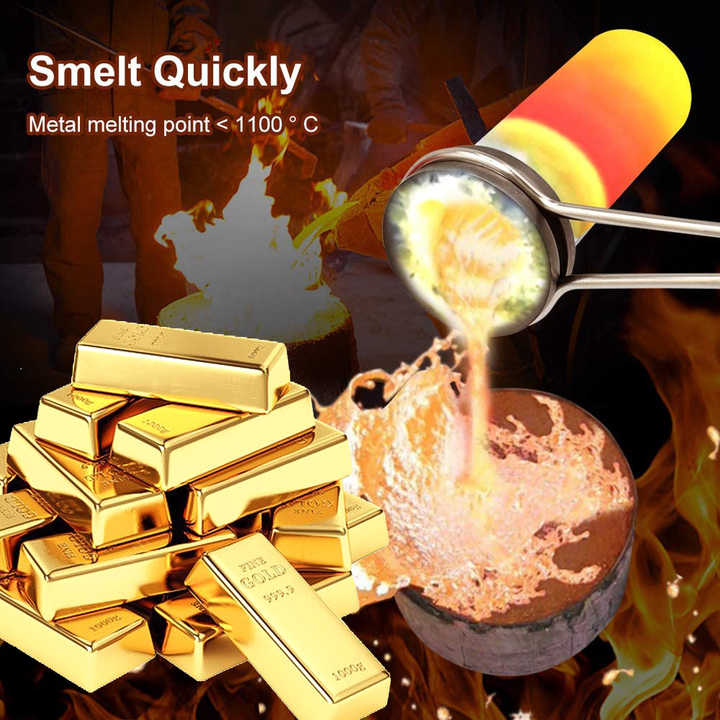

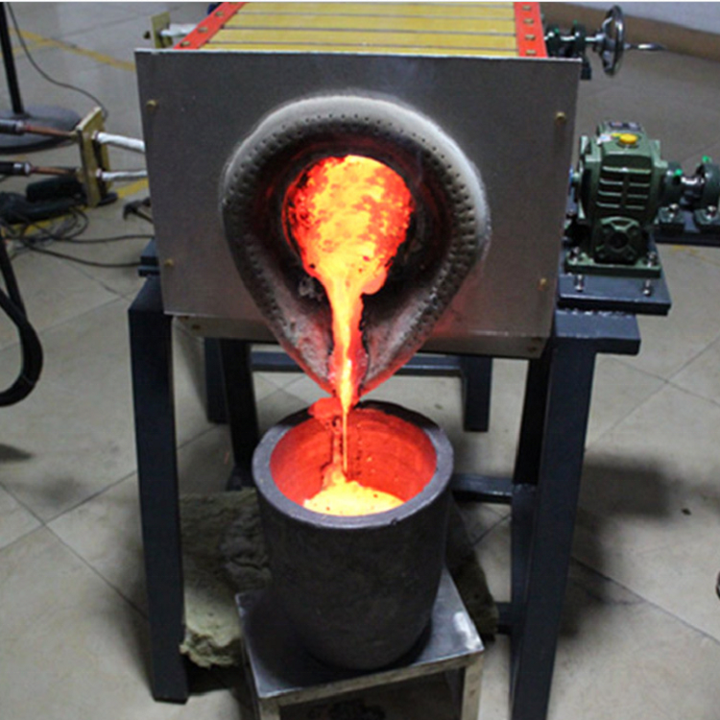

When it comes to smelting gold, a crucible plays a crucial role in the process. A crucible is a container that can withstand high temperatures and is used for melting metals and other materials in a furnace. It is essential for anyone involved in the gold smelting process, whether on a small or large scale. In this article, we will explore the importance of a crucible for gold smelting, the materials used to make them, and how to select the right one for your smelting needs.

What is a Crucible?

A crucible is a heat-resistant container used in various industries, especially in metalworking and chemistry. For gold smelting, the crucible holds the gold as it is heated to extreme temperatures until it melts. The crucible must endure the intense heat without breaking down, contaminating the gold, or interacting with the chemicals involved in the smelting process.

Types of Crucibles for Gold Smelting

Crucibles come in various materials, each with its own set of advantages depending on the specific smelting environment. Here are some common types used in gold smelting:

1. Graphite Crucibles

Graphite crucibles are among the most popular for gold smelting due to their high thermal conductivity and resistance to high temperatures. They are particularly well-suited for melting precious metals like gold because they do not react with the metal or absorb impurities.

- Pros: Excellent heat resistance, non-reactive with gold, affordable.

- Cons: Can be brittle and break if handled improperly.

2. Silicon Carbide Crucibles

Silicon carbide crucibles are known for their durability and resistance to chemical reactions. These crucibles are ideal for high-temperature smelting and offer a longer lifespan than graphite crucibles.

- Pros: High strength, longer lifespan, resistant to chemical corrosion.

- Cons: More expensive than graphite crucibles.

3. Ceramic Crucibles

Ceramic crucibles are another option for gold smelting. They can withstand extreme heat and are used in traditional and modern smelting techniques. Ceramic crucibles are often lined with refractory material to increase their heat resistance.

- Pros: Withstands very high temperatures, durable.

- Cons: Can be heavier and more fragile than other types of crucibles.

4. Clay Graphite Crucibles

These crucibles combine the properties of both clay and graphite, offering a balance between heat resistance and affordability. Clay graphite crucibles are commonly used for melting smaller quantities of gold and are popular for hobbyists.

- Pros: Affordable, good thermal conductivity.

- Cons: May not last as long as silicon carbide or ceramic crucibles in high-volume smelting operations.

How to Choose the Right Crucible for Gold Smelting

When selecting a crucible for gold smelting, there are several factors to consider to ensure that you get the right one for your specific needs:

1. Temperature Resistance

Since gold melts at around 1,064°C (1,947°F), you need a crucible that can withstand temperatures higher than this without breaking down. Graphite, silicon carbide, and ceramic crucibles are all excellent choices for handling these high temperatures.

2. Durability and Longevity

For frequent or large-scale smelting operations, the durability of your crucible is essential. Silicon carbide crucibles, for example, tend to last longer than graphite crucibles, making them a good option for extended use. However, they can be more expensive, so consider your budget and smelting frequency.

3. Non-Reactivity

Gold is a highly valuable metal, and any impurities introduced during smelting can reduce its purity. Choose a crucible that is non-reactive and will not introduce contaminants. Graphite and silicon carbide crucibles are both excellent options for preserving the purity of the gold.

4. Size and Capacity

The size of the crucible should match the amount of gold you plan to smelt. Hobbyists may only need a small crucible for occasional use, while industrial gold smelting operations will require larger and more durable crucibles.

Maintaining Your Crucible

Proper care and maintenance of your crucible will extend its lifespan and ensure consistent results. Here are some tips to maintain your crucible:

- Preheat the Crucible: Gradually preheating the crucible before use can help prevent thermal shock and cracking.

- Handle with Care: Crucibles can be fragile, so handle them carefully, especially when moving them in and out of a furnace.

- Avoid Overfilling: Never overfill the crucible, as this can cause the molten gold to spill over and potentially damage the crucible or furnace.

A high-quality crucible for gold smelting is essential for achieving a successful smelting process. Whether you are a hobbyist melting small amounts of gold or part of an industrial operation, selecting the right crucible is key to ensuring the gold’s purity and efficiency in the smelting process. With materials like graphite, silicon carbide, and ceramic available, each offering unique benefits, you can choose the one that best suits your needs. Proper care and maintenance of your crucible will further ensure its longevity and performance, making it an invaluable tool in your gold smelting endeavors.