crucible gold smelting

Crucible Gold Smelting: A Key Component in Gold Refining

When it comes to refining gold, one of the most essential tools is the crucible for gold smelting. This equipment is specifically designed to withstand the high temperatures needed to melt gold and separate it from impurities. In this article, we will explore what crucible gold smelting is, the different types of crucibles available, how to use them, and why they are critical in the gold refining process.

What Is Crucible Gold Smelting?

Crucible gold smelting refers to the process of heating gold in a special container known as a crucible, which is resistant to extreme heat. This method is used to melt down raw gold or scrap gold, allowing impurities to be removed and pure gold to be collected. The smelting process is crucial in both small-scale refining operations and industrial-scale gold production.

How Does Crucible Gold Smelting Work?

The process of gold smelting in a crucible involves several steps, each of which contributes to the refining of gold. Here’s a simplified overview:

- Preparation of Gold Material: Whether you’re working with raw gold ore, gold scrap, or old jewelry, the gold material is first prepared by cleaning it of any debris or contaminants.

- Selecting the Crucible: A suitable crucible is chosen based on the amount of gold to be melted and the type of furnace used. Common materials for crucibles include graphite, ceramic, and silicon carbide, as these can withstand temperatures of over 1000°C.

- Adding Flux: Flux is added to the crucible along with the gold. Flux materials, such as borax or silica, help to bind impurities, making it easier to separate them from the molten gold.

- Melting the Gold: The crucible is placed inside a furnace or a blowtorch flame, and the gold is heated until it reaches its melting point, which is about 1064°C (1947°F). As the gold melts, impurities either rise to the surface or bond with the flux to form slag, a byproduct that can be removed.

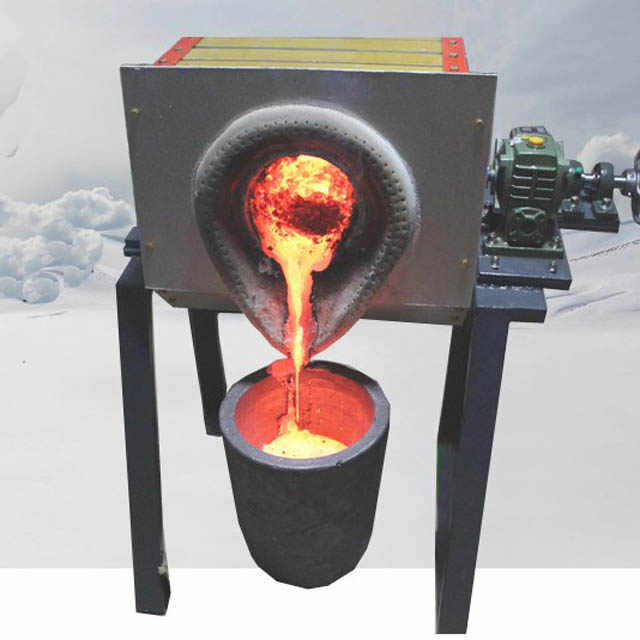

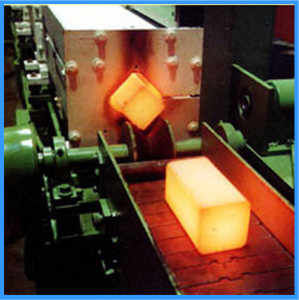

- Pouring the Molten Gold: Once the gold has melted and the impurities have been separated, the molten gold is poured into molds to form ingots or bars. The crucible is carefully handled using tongs, as the material inside remains extremely hot.

- Cooling and Final Refinement: The gold is allowed to cool and solidify. Depending on the desired level of purity, further refining methods, such as acid treatment or electrolysis, may be employed to achieve high-purity gold.

Types of Crucibles for Gold Smelting

There are various types of crucibles available for gold smelting, each suited for different scales of refining and specific furnace types. Here are some of the most common types:

1. Graphite Crucibles

Graphite crucibles are highly popular for smelting gold because they are extremely heat-resistant and conduct heat evenly. They are durable and can withstand repeated use in both propane and electric furnaces. Graphite is also non-reactive, ensuring it does not contaminate the gold during the smelting process.

2. Ceramic Crucibles

Ceramic crucibles are widely used for smelting because they can endure very high temperatures without cracking or melting. These crucibles are more affordable than graphite and are often used for smaller-scale operations. However, they may not last as long due to their susceptibility to thermal shock.

3. Silicon Carbide Crucibles

Silicon carbide crucibles offer excellent heat resistance and durability, making them ideal for smelting high volumes of gold in industrial settings. These crucibles are more expensive but have a longer lifespan and are capable of withstanding very high temperatures, making them well-suited for heavy-duty use.

Why Crucibles Are Important in Gold Smelting

The crucible plays an essential role in gold smelting for several reasons:

- Heat Resistance: Crucibles are designed to endure extremely high temperatures without breaking down or contaminating the metal being smelted.

- Efficiency: By providing even heat distribution and resistance to chemical reactions, crucibles help to ensure that the smelting process is smooth and that gold is melted efficiently without unnecessary loss of material.

- Durability: Crucibles are built to withstand repeated cycles of heating and cooling, making them a cost-effective choice for gold refiners who require long-lasting equipment.

- Purity of the Final Product: The choice of crucible can have a direct impact on the quality of the final gold product. Non-reactive crucibles prevent contamination of the molten gold, helping to achieve higher levels of purity.

How to Choose the Right Crucible for Gold Smelting

Selecting the right crucible is crucial for successful gold smelting. Here are some factors to consider:

- Capacity: The size of the crucible should match the amount of gold you plan to smelt. For small-scale operations, smaller ceramic or graphite crucibles may suffice, while larger industrial smelting requires higher-capacity silicon carbide crucibles.

- Heat Source Compatibility: Ensure that the crucible material is compatible with your furnace or heat source. Some crucibles are designed specifically for use with electric furnaces, while others are better suited for use with gas or propane torches.

- Durability: If you plan to smelt gold frequently, investing in a more durable crucible, such as one made of graphite or silicon carbide, may save money in the long run due to its longer lifespan.

- Non-Reactivity: Choose a crucible that is non-reactive with gold to ensure that the smelting process results in pure, uncontaminated gold.

Crucible gold smelting is an essential part of the gold refining process, providing a controlled environment for melting gold and separating it from impurities. Whether you’re a hobbyist refining small amounts of scrap gold or a professional working with larger quantities, choosing the right crucible is critical to achieving efficient smelting results. With various types of crucibles available, including graphite, ceramic, and silicon carbide, there is a solution for every level of gold smelting operation. By understanding how crucibles work and selecting the right one for your needs, you can ensure the successful refinement of pure, high-quality gold.