Cupel For Refining Gold

Understanding the Importance of Cupel for Refining Gold

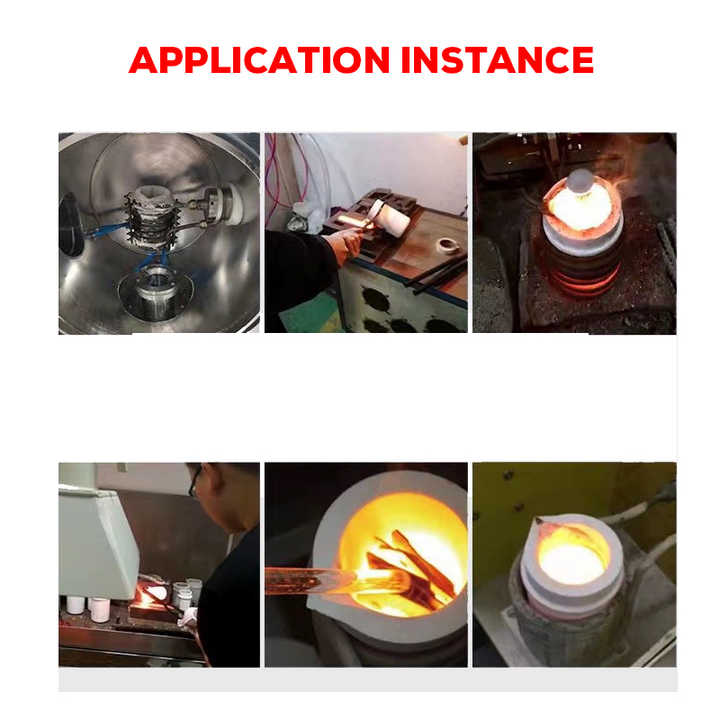

Gold refining is an intricate process that requires precision and expertise to ensure the highest purity levels. One essential tool in this process is the cupel—a small, refractory ceramic dish used specifically for refining precious metals, including gold. FRT Machinery, a leader in providing advanced solutions for the metallurgical industry, emphasizes the importance of using high-quality cupels in their refining processes.

The Role of Cupel in Gold Refining

The cupel plays a crucial role in separating base metals from gold through a process known as cupellation. This method has been utilized for centuries due to its effectiveness in purifying gold by oxidizing and removing impurities. When gold is heated in a cupel, silver and other base metals form an oxide that can be scraped away, leaving behind pure gold. FRT Machinery ensures that their cupels are designed to withstand the extreme temperatures required for this process, enhancing efficiency and safety.

Selecting the Right Cupel for Refining Gold

Not all cupels are created equal. Choosing the right one for refining gold depends on several factors such as temperature resistance, chemical stability, and durability. FRT Machinery recommends selecting cupels made from materials like bone ash or graphite, which have excellent thermal properties and can resist the corrosive effects of molten metals. These characteristics make them ideal for achieving optimal results in gold refining applications.

Benefits of Using Cupel for Refining Gold

Using a cupel for refining gold offers numerous benefits over other methods. Firstly, it allows for the precise separation of gold from other metals, ensuring a higher purity level. Secondly, the process is relatively simple and cost-effective once the setup is complete. Lastly, because cupellation does not involve harmful chemicals, it is environmentally friendly compared to some alternative refining techniques. FRT Machinery’s cupels are engineered to maximize these benefits, making them a preferred choice among gold refiners worldwide.

Techniques for Effective Cupellation with Cupel

To achieve the best results when refining gold with a cupel, certain techniques must be followed carefully. Proper preparation of the sample, controlled heating, and accurate scraping of residues are critical steps. FRT Machinery provides comprehensive guidelines on how to perform these tasks efficiently, helping users get the most out of their cupels while maintaining safety standards.

Maintenance and Longevity of Cupel Used in Gold Refining

Proper maintenance of your cupel is key to extending its lifespan and ensuring consistent performance during gold refining operations. Regular cleaning, inspection for cracks or damage, and storage in a dry environment are recommended practices. FRT Machinery also offers specialized maintenance services designed to keep your cupels in top condition, thereby reducing downtime and maximizing productivity in your refining process.

Innovations in Cupel Technology for Enhanced Gold Refining

As technology advances, so too does the design and functionality of tools like the cupel. FRT Machinery invests heavily in research and development to create innovative solutions that improve upon traditional cupellation methods. Their latest cupels feature enhanced heat distribution, improved material composition, and ergonomic designs that make gold refining safer, faster, and more effective than ever before. By staying at the forefront of innovation, FRT Machinery continues to set new standards in the field of gold refining equipment.