Cyanide Gold Refining

Cyanide Gold Refining: An In-depth Look into the Process and Its Applications

Cyanide Gold Refining: A Fundamental Overview

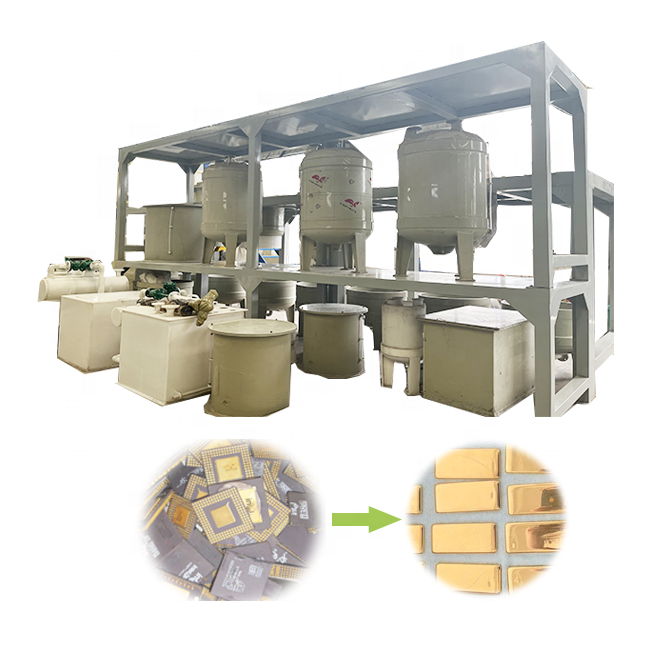

Gold refining is a crucial process in the extraction and purification of gold from its ore. Among various methods, cyanide gold refining stands out for its efficiency and widespread adoption in the industry. This technique involves the use of sodium cyanide (NaCN) or potassium cyanide (KCN) to dissolve gold and silver from their ores, making it easier to separate these precious metals from unwanted materials. FRT Machinery, a leading manufacturer of refining equipment, has significantly contributed to the advancement of this method by developing robust and eco-friendly solutions.

Advantages of Using Cyanide in Gold Refining

The utilization of cyanide in gold refining offers several advantages over traditional smelting techniques. Firstly, it enables the processing of lower-grade ores that would otherwise be uneconomical to refine. Secondly, cyanide gold refining allows for a higher recovery rate of gold, typically ranging between 90% to 98%, depending on the quality of the ore and the efficiency of the process. FRT Machinery’s innovative systems ensure optimal performance, maximizing yields while minimizing environmental impact.

Environmental Considerations in Cyanide Gold Refining

Despite its effectiveness, cyanide gold refining raises concerns regarding environmental safety due to the toxic nature of cyanide compounds. Proper handling and disposal of cyanide waste are critical to prevent contamination of water sources and soil. Recognizing these challenges, FRT Machinery designs its equipment with advanced safety features and closed-loop systems that minimize the risk of leaks and spills. Additionally, they offer comprehensive training programs for operators to ensure safe practices throughout the refining process.

The Role of FRT Machinery in Enhancing Cyanide Gold Refining

As a pioneer in the field, FRT Machinery continuously strives to improve cyanide gold refining technologies. Their latest refinements focus on reducing cyanide consumption, enhancing metal recovery rates, and ensuring compliance with stringent environmental regulations. By investing heavily in research and development, FRT Machinery aims to set new standards for efficiency and sustainability within the gold refining industry.

Future Trends in Cyanide Gold Refining

Looking ahead, the future of cyanide gold refining appears promising, driven by technological innovations and stricter environmental policies. Innovations like bioleaching and the use of alternative lixiviants might eventually complement or replace traditional cyanide-based processes. However, given the current economic and technical feasibility, cyanide will likely remain a cornerstone of gold refining for years to come. FRT Machinery remains committed to supporting the industry through continuous improvement and adaptation to emerging trends.

Conclusion on the Importance of Cyanide Gold Refining

In conclusion, cyanide gold refining plays a vital role in modern gold production, offering unparalleled efficiency and cost-effectiveness. While environmental concerns must be addressed, ongoing advancements by companies like FRT Machinery promise a sustainable future for this essential process. As the demand for gold continues to grow, so too will the importance of refining technologies that can meet this demand responsibly and efficiently.