electric diode gold purification process

Introduction to the Electric Diode Gold Purification Process

The electric diode gold purification process is an innovative method used to refine gold by utilizing the principles of electrochemistry. This technique involves the use of electric diodes to selectively purify gold from raw materials, separating it from other metals and impurities. With the growing demand for high-purity gold in various industries such as electronics, jewelry, and investment, the electric diode gold purification process is becoming an increasingly popular choice due to its efficiency and environmental benefits.

The Basics of the Electric Diode Gold Purification Process

The electric diode gold purification process is based on the principles of electrolysis, where an electric current is passed through a solution containing dissolved gold ions. This current drives the migration of gold ions toward an electrode, usually a cathode, where they are deposited as pure gold. The use of electric diodes helps control the flow of current and the selective deposition of gold, enhancing the overall efficiency of the purification process.

Electrolysis and Its Role in Gold Purification

In the electric diode gold purification process, electrolysis plays a key role. During electrolysis, an electric current passes through an electrolyte solution, typically a gold chloride solution. As the current flows, gold ions migrate to the cathode, where they gain electrons and are reduced to solid gold. At the same time, impurities and other metals remain dissolved in the solution or migrate to the anode, where they can be removed.

Electric Diodes and Their Function

Electric diodes are essential components in this process, as they allow the current to flow in only one direction, ensuring that the electrochemical reaction proceeds smoothly. The diodes help to regulate the current, making the gold deposition more controlled and precise. This results in a more efficient and reliable method for purifying gold, especially when dealing with complex mixtures containing other metals.

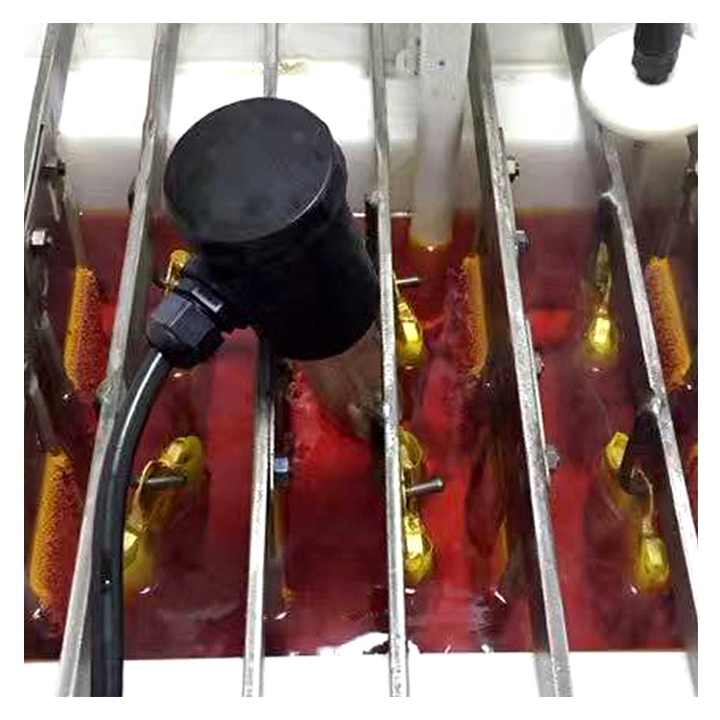

The Electric Diode Gold Purification Process in Detail

The electric diode gold purification process is typically carried out in a series of steps, including gold dissolution, electrochemical deposition, and the recovery of purified gold. This process is highly effective in producing gold with a high degree of purity, suitable for industrial and commercial use.

Dissolving Gold in Solution

The first step in the electric diode gold purification process involves dissolving the gold into an electrolyte solution. This is usually achieved by reacting the gold with a mixture of chemicals, such as hydrochloric acid and chlorine, to form gold chloride. The resulting solution contains gold ions, which are ready for the electrochemical purification process.

Electrochemical Deposition Using Diodes

Once the gold is dissolved in the electrolyte, the electric diode gold purification process uses electrolysis to deposit pure gold onto the cathode. The electric diodes ensure that the current flows in the correct direction, allowing for a controlled and efficient deposition of gold. As the gold ions in the solution migrate to the cathode, they are reduced to their metallic form, accumulating as pure gold.

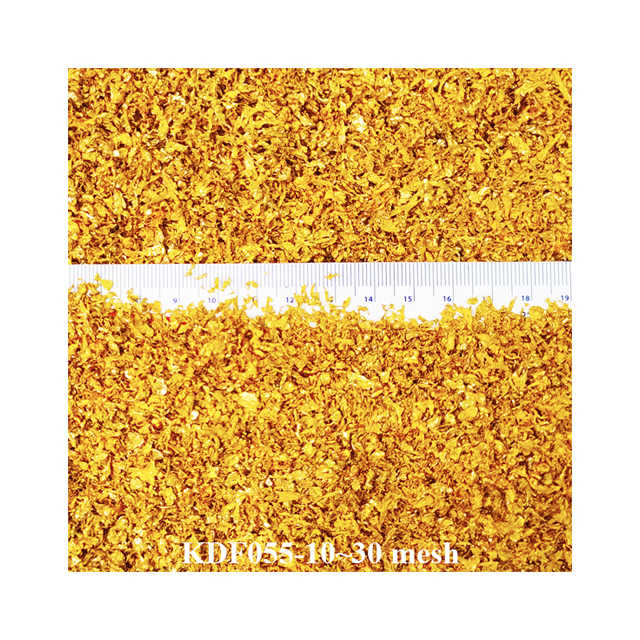

Recovery and Purification of Gold

After the electrochemical deposition, the purified gold is collected from the cathode. This gold is typically washed and dried to remove any remaining electrolyte solution. The final product is highly pure gold, often exceeding 99.9% purity, which can be used in various applications, including electronics, jewelry manufacturing, and bullion production.

Advantages of the Electric Diode Gold Purification Process

The electric diode gold purification process offers several advantages over traditional gold refining methods. These benefits make it an attractive option for both small-scale refiners and large industrial operations seeking efficient and environmentally friendly gold purification techniques.

High Purity Levels

One of the main advantages of the electric diode gold purification process is its ability to produce gold with very high purity levels. By controlling the electrochemical reactions using electric diodes, the process ensures that only gold is deposited onto the cathode, leaving impurities behind in the solution. This results in gold that meets the stringent purity requirements of various industries.

Energy Efficiency and Environmental Benefits

The electric diode gold purification process is also more energy-efficient compared to other methods, such as smelting. The use of electric diodes helps to minimize energy consumption by regulating the flow of current and reducing the overall power required for electrolysis. Additionally, this process generates fewer harmful by-products, making it a more environmentally friendly option for gold purification.

Scalability and Versatility

Another benefit of the electric diode gold purification process is its scalability. This method can be adapted to suit both small-scale operations and large industrial settings, making it a versatile choice for gold refiners. Whether purifying small quantities of gold from scrap or refining large amounts of raw gold, the electric diode process offers consistent and reliable results.

Applications of the Electric Diode Gold Purification Process

The electric diode gold purification process is used in a variety of industries that require high-purity gold. Its precision and efficiency make it ideal for producing gold for specialized applications, particularly in sectors where even the smallest impurities can affect performance.

Electronics Industry

In the electronics industry, gold is often used in components such as connectors and circuit boards due to its excellent conductivity and resistance to corrosion. The electric diode gold purification process ensures that the gold used in these components is free from impurities, which can negatively impact the performance and longevity of electronic devices.

Jewelry and Investment Gold

For the jewelry and investment sectors, the electric diode gold purification process produces gold of the highest quality. Jewelry manufacturers and investors alike require gold that is not only visually appealing but also of high purity. The electric diode process meets these demands, producing gold that is suitable for luxury items and investment-grade bullion.

The electric diode gold purification process represents a significant advancement in gold refining technology. By utilizing electric diodes and electrochemical principles, this process offers a highly efficient, precise, and environmentally friendly method for purifying gold. With its ability to produce gold of exceptional purity, the electric diode gold purification process is a valuable tool for industries ranging from electronics to jewelry manufacturing, ensuring the production of top-quality gold for a variety of applications.