electrolytic gold refining machine

Understanding the Electrolytic Gold Refining Machine

In the field of metallurgy and precious metal purification, the electrolytic gold refining machine stands out as one of the most advanced and efficient methods for refining gold. This machine is specifically designed to purify gold using electrolysis, ensuring a high level of precision and purity. From large-scale industrial applications to smaller-scale operations, electrolytic gold refining machines play a crucial role in the gold refining process. This article delves into how these machines work, their benefits, and the key components involved in their operation.

How an Electrolytic Gold Refining Machine Works

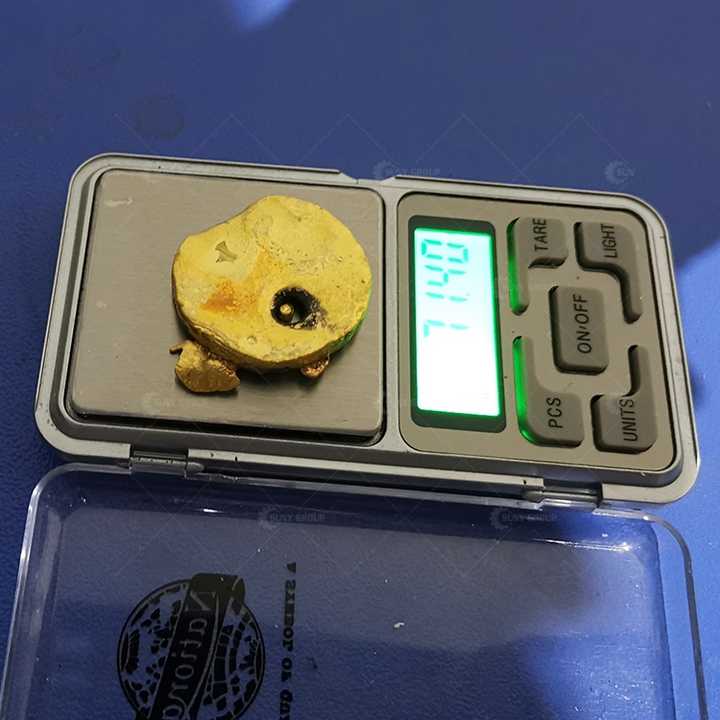

The electrolytic gold refining machine operates on the principle of electrolysis, where gold is dissolved from an impure anode and deposited onto a pure gold cathode. The process starts with gold, often in the form of a gold alloy, being placed into an electrolyte solution. A low-voltage electrical current is passed through the solution, causing gold ions to move from the anode (impure gold) to the cathode (pure gold). Over time, the impurities separate from the gold, leaving behind highly refined gold with a purity level of 99.99%.

Benefits of Using an Electrolytic Gold Refining Machine

Using an electrolytic gold refining machine offers a number of advantages, making it the preferred choice for many in the gold refining industry. First, the process yields gold with extremely high purity, which is essential for industries like electronics, jewelry, and investment. Second, it is an efficient and cost-effective method. The electrolyte solution can be reused, and the machine can run continuously for long periods, allowing for greater productivity.

Additionally, the electrolytic process is more environmentally friendly compared to older methods that relied on toxic chemicals like mercury or cyanide. By using an electrolytic gold refining machine, gold refiners can minimize waste and reduce harmful emissions, making it a more sustainable option.

Key Components of an Electrolytic Gold Refining Machine

An electrolytic gold refining machine consists of several essential parts that work together to ensure the success of the refining process. These include:

- Electrolyte Tank: The electrolyte tank holds the solution, typically a chloride or cyanide mixture, which allows the dissolution and deposition of gold.

- Anode and Cathode: The impure gold is placed as the anode, while a pure gold plate serves as the cathode where the refined gold is deposited.

- Power Supply: The machine uses a low-voltage power supply to pass a current through the electrolyte, which drives the electrochemical reactions.

- Filtration System: Some machines come equipped with filtration systems to remove impurities and solid particles from the solution.

Choosing the Right Electrolytic Gold Refining Machine

When selecting an electrolytic gold refining machine, several factors should be considered. The machine’s capacity is crucial, as it determines how much gold can be refined at a time. For larger industrial refineries, high-capacity machines are ideal, while smaller operations may benefit from compact machines that offer flexibility.

The type of electrolyte solution used by the machine is another important factor. Most machines use either chloride-based or cyanide-based solutions, with chloride being more common due to safety concerns with cyanide. The choice of electrolyte will depend on the specific needs of the refining process.

Maintenance and Care of an Electrolytic Gold Refining Machine

Regular maintenance is essential to ensure the longevity and optimal performance of an electrolytic gold refining machine. Operators should periodically inspect the anodes and cathodes for wear, as the electrolysis process can cause them to degrade over time. The electrolyte solution also needs to be tested and replaced as necessary to maintain its effectiveness. Proper cleaning of the tank and filtration system will help avoid contamination and ensure consistent results.

The Role of Electrolytic Gold Refining Machines in Industry

Electrolytic gold refining machines are used in a wide range of industries. For instance, in the jewelry industry, they are essential for producing gold of the highest quality, free from impurities. In electronics, gold needs to be extremely pure to function effectively in circuits and connectors. Even in investment, gold that has been refined through electrolysis is preferred due to its superior purity and value.

Future Trends in Electrolytic Gold Refining Machines

As technology advances, the design and efficiency of electrolytic gold refining machines continue to improve. Innovations in automation are making it possible for machines to operate with minimal human intervention, further increasing their productivity and reliability. Additionally, improvements in the environmental safety of these machines are helping the industry move toward more sustainable practices.

Conclusion

The electrolytic gold refining machine represents a major advancement in the purification of gold. Its ability to produce gold with exceptionally high purity, while offering an environmentally friendly and efficient solution, makes it indispensable in industries that rely on high-quality gold. By understanding how these machines work and their role in refining, businesses can make informed decisions to improve their gold refining processes.