electrolytic purification of gold

Electrolytic Purification of Gold: A Modern Approach to Refining

The electrolytic purification of gold is a highly efficient method used to refine gold to a high degree of purity. This process has become increasingly important in industries such as jewelry making, electronics, and investment-grade bullion production, where the demand for pure gold is constantly growing. Electrolytic purification offers a modern solution for achieving the highest standards of gold purity, with precision and efficiency that surpass traditional methods.

What Is Electrolytic Purification of Gold?

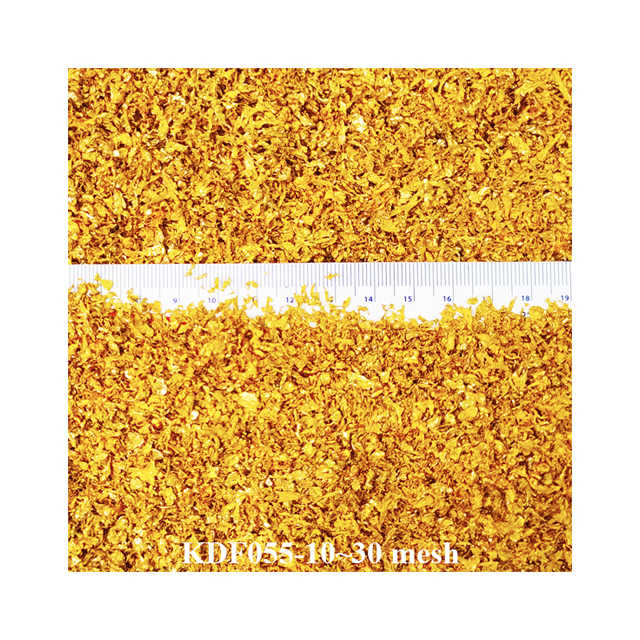

At its core, the electrolytic purification of gold is a process that involves passing an electric current through a solution containing gold. This causes gold ions to move from a less pure anode (typically composed of impure gold) to a cathode, which collects the pure gold. The impurities that are left behind settle as a byproduct, known as anode slime. Through this process, gold can be refined to a purity level of 99.99%, making it suitable for the most demanding applications.

This method of gold purification is not only efficient but also environmentally friendly compared to traditional fire-based refining processes. It allows for the recovery of additional valuable metals like silver and platinum that may be present in the anode.

The Electrolytic Purification Process

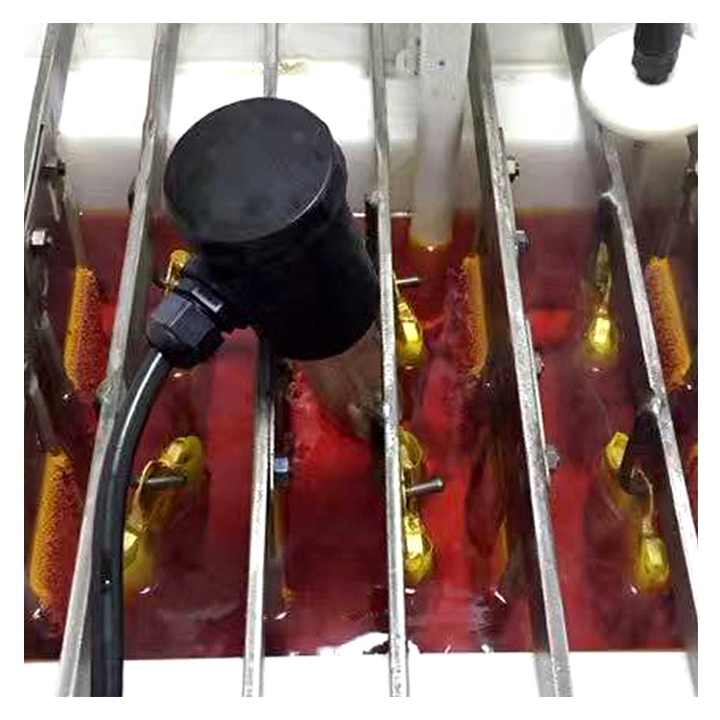

The electrolytic purification of gold involves several key steps to ensure that the gold is purified to the desired standard. The process begins by immersing a gold anode into a specially prepared electrolyte solution, usually containing chloride or cyanide ions. A cathode, typically made of stainless steel or pure gold, is also submerged in the same solution. When an electric current is applied, gold from the anode dissolves into the solution as gold ions and is deposited onto the cathode as pure gold.

During this process, any impurities in the anode, such as copper, lead, or other base metals, do not dissolve and instead settle at the bottom of the tank as sludge. This sludge can contain other precious metals like silver or platinum, which can also be recovered and refined separately.

The amount of time the gold spends in the electrolytic bath and the strength of the electric current applied are both carefully controlled to maximize the purity of the final product.

Benefits of Electrolytic Purification of Gold

The electrolytic purification of gold offers several distinct advantages over other refining methods. First and foremost, it achieves an exceptionally high level of purity. While traditional methods such as smelting can remove many impurities, they often fall short of the purity achieved through electrolysis. This makes the electrolytic process ideal for applications where the purest gold is required, such as in electronics and high-end jewelry.

Additionally, this method is more environmentally friendly. By using an electrolyte solution instead of harsh chemicals or high temperatures, electrolytic purification reduces the environmental impact of gold refining. This makes it a preferred choice for companies that prioritize sustainability in their operations.

The process is also highly efficient. Once set up, electrolytic purification can be automated, allowing for large quantities of gold to be refined continuously with minimal human intervention. This lowers labor costs and increases overall production capacity.

Applications of Electrolytic Purification in Industry

Industries that require exceptionally pure gold rely heavily on the electrolytic purification of gold. One of the most significant users of this refined gold is the electronics industry. Gold’s excellent conductivity and resistance to corrosion make it essential for manufacturing components such as connectors and circuit boards. The high purity achieved through electrolysis ensures that these components perform reliably in even the most demanding environments.

The jewelry industry also benefits from the electrolytic purification process. Consumers demand high-purity gold in luxury items, and the ability to refine gold to 99.99% purity through this method ensures that jewelers can meet these expectations. Additionally, the electrolytic process allows for the recovery of other precious metals, which can be used in the creation of unique jewelry pieces.

Investment-grade bullion, too, requires the highest levels of purity to ensure that it retains its value over time. The electrolytic purification of gold ensures that bullion meets international standards for purity, making it suitable for investment purposes.

Environmental and Economic Considerations

In an era where sustainability is becoming increasingly important, the electrolytic purification of gold presents a more environmentally friendly option compared to traditional methods. It produces fewer emissions, requires less energy, and uses recyclable materials, which reduces waste.

From an economic standpoint, the electrolytic process is also highly cost-effective. Its ability to process large volumes of gold quickly and efficiently makes it ideal for large-scale operations. Furthermore, the recovery of additional precious metals during the process adds further value, increasing the profitability of the refining operation.

The electrolytic purification of gold is a cutting-edge technique that has revolutionized the way gold is refined. With its high levels of purity, environmental benefits, and efficiency, this process is integral to industries that rely on pure gold, including electronics, jewelry, and bullion production. As the demand for pure gold continues to grow, the electrolytic purification method will remain a vital component in the refinement process, ensuring both quality and sustainability in gold production.