forms of purification gold

Forms of Purification for Gold: Understanding the Techniques

Gold is one of the most valuable metals in the world, prized for its purity and various applications in industries such as jewelry, electronics, and investment. However, raw gold often contains impurities that need to be removed to achieve the desired purity. Over the centuries, several forms of purification for gold have been developed to ensure its quality. In this article, we will explore these different methods, explaining how they work and their significance in the modern world.

Fire Assaying: A Traditional Method

One of the oldest forms of purification for gold is fire assaying. This process has been used for centuries and remains a reliable method to purify gold. Fire assaying involves melting the gold at high temperatures in the presence of lead or other flux materials that bind to the impurities. The molten mixture is then poured into a mold, where the lead and impurities separate from the gold.

This method is particularly effective in isolating gold from other metals such as silver, copper, and iron. Fire assaying is still widely used today, particularly in mining and jewelry industries, where small quantities of gold need to be purified efficiently.

Electrolytic Refining: A Modern Approach

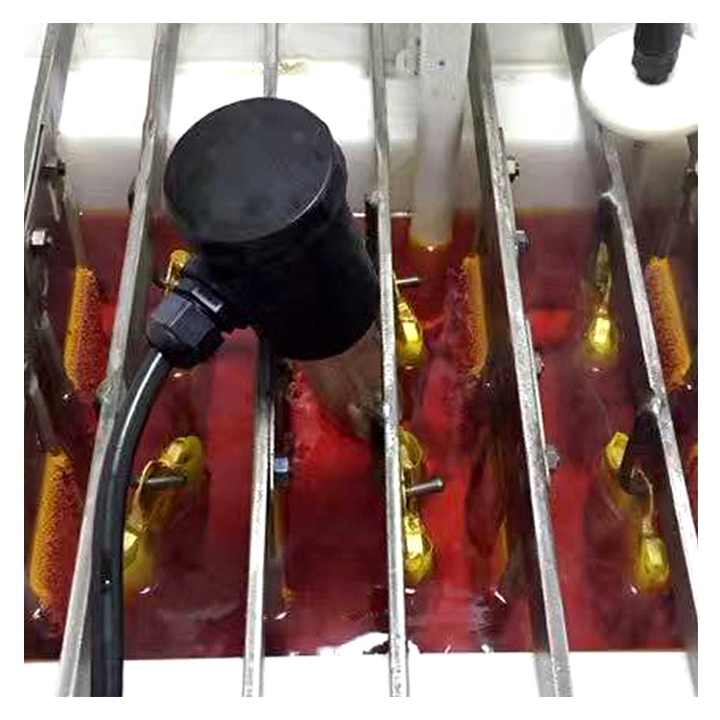

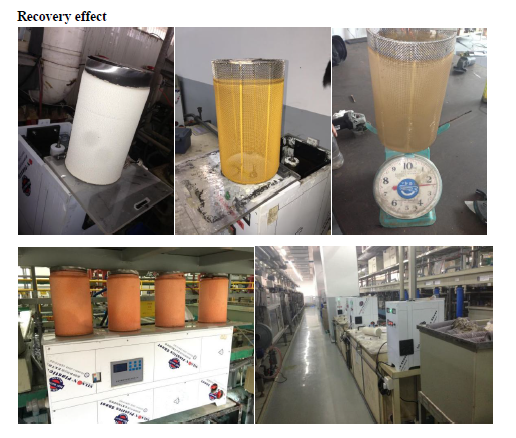

Electrolytic refining is one of the more advanced forms of purification for gold and is commonly used for large-scale industrial applications. In this process, gold is dissolved in a chemical solution, typically an electrolyte containing hydrochloric acid and chlorine. An electric current is passed through the solution, causing pure gold to deposit onto a cathode, while impurities remain in the electrolyte.

This method allows for the production of extremely high-purity gold, often exceeding 99.9% purity. Electrolytic refining is particularly popular in industries such as electronics, where high levels of gold purity are required for components like circuit boards and connectors.

Aqua Regia: A Powerful Chemical Solution

Aqua regia, a mixture of hydrochloric acid and nitric acid, is one of the most effective forms of purification for gold. It dissolves gold into a liquid form, allowing for the separation of impurities. Once the gold is dissolved, various chemical treatments are applied to precipitate the pure gold out of the solution.

This method is highly effective for refining gold from complex mixtures or heavily contaminated raw materials. Aqua regia is often used in laboratories and smaller-scale refining operations due to its versatility and ability to handle difficult purification tasks.

The Miller Process: Efficient for Large Quantities

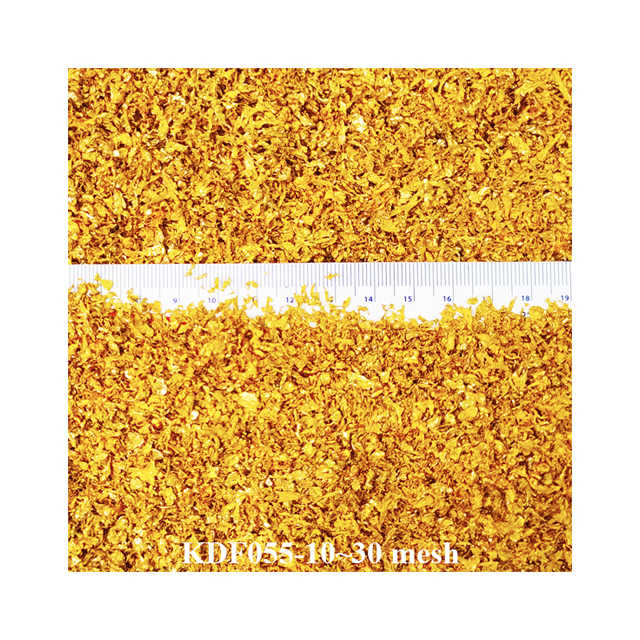

The Miller Process is another industrial-scale method that is one of the more widely used forms of purification for gold. In this process, gold is melted and chlorine gas is passed through the molten mixture. The chlorine reacts with impurities like silver and base metals, forming chlorides that can be easily removed from the surface of the gold.

Although the Miller Process produces gold that is around 99.5% pure, it is a fast and cost-effective method for refining large quantities of gold. The process is commonly used in commercial gold refineries where speed and efficiency are key factors.

The Wohlwill Process: For Ultra-Pure Gold

For those seeking the highest levels of purity, the Wohlwill Process is the ideal choice. It is a highly specialized and precise method used in certain forms of purification for gold, especially when producing gold for investment purposes or high-tech applications. The process uses electrolysis, similar to electrolytic refining, but with tighter controls and more specific chemical solutions.

The Wohlwill Process is capable of producing gold that is 99.99% pure, making it one of the most refined purification methods available. This method is often used by mints and in industries where only the purest gold is acceptable.

Green Purification Techniques: A Growing Trend

As environmental concerns grow, the gold industry is increasingly adopting eco-friendly forms of purification for gold. One such method is biological leaching, which uses microorganisms to extract and purify gold from ore. This process eliminates the need for harmful chemicals and reduces the environmental impact of gold refining.

Another approach is the use of environmentally safe chemicals in traditional refining processes, helping to minimize pollution and improve sustainability in gold purification. These green techniques are gaining popularity, especially among companies looking to balance efficiency with environmental responsibility.

Gold purification has evolved over time, with different forms of purification for gold available to suit various needs. From traditional fire assaying to modern electrolysis and green purification methods, each approach offers unique advantages depending on the scale and purity required. Understanding these techniques is crucial for industries that rely on high-quality gold, ensuring that the precious metal meets the stringent standards demanded by today’s markets.