fully automatic gold refining machine

Fully Automatic Gold Refining Machine Revolutionizing Gold Refining Processes

The advent of modern technology has significantly transformed industries, and the gold refining sector is no exception. One of the most remarkable innovations in this industry is the fully automatic gold refining machine, which has revolutionized the way gold is purified. This machine provides a more efficient, safer, and environmentally friendly alternative to traditional refining methods. Whether for large-scale industrial purposes or smaller operations, this automated solution is becoming the preferred choice for many refiners.

What is a Fully Automatic Gold Refining Machine?

A fully automatic gold refining machine is a technologically advanced device designed to automate the gold purification process. Unlike traditional methods that involve manual labor, chemicals, and risk, this machine performs the entire refining process autonomously. It is capable of refining scrap gold, old jewelry, or gold from electronic components into pure gold with a high level of precision and efficiency.

Key Features of a Fully Automatic Gold Refining Machine

One of the main selling points of these machines is their automation. With a fully automatic gold refining machine, the entire process, from loading raw material to collecting refined gold, is managed without human intervention. These machines are equipped with modern sensors, programmable logic controllers (PLCs), and user-friendly interfaces that make them easy to operate.

How Does a Fully Automatic Gold Refining Machine Work?

The operation of a fully automatic gold refining machine is based on the latest advancements in electrochemical and chemical refining techniques. Here’s a breakdown of how the process works:

Loading Raw Material

The process begins by loading the gold material into the machine. This could be gold jewelry, scrap, or electronic components. The machine is designed to handle various types of raw materials that contain gold, making it versatile for different refining needs.

Electrolytic Refining Process

Most fully automatic gold refining machines use an electrolytic refining process. In this method, the gold material is dissolved in an electrolyte solution. A current is passed through the solution, which causes pure gold to deposit onto the cathode. Impurities, such as other metals, remain in the electrolyte or settle out as waste. This method is highly efficient, producing gold of extremely high purity.

Collection of Pure Gold

Once the refining process is complete, the machine collects the pure gold in the form of bars or powder, depending on the user’s requirements. This step is fully automated, ensuring a safe and efficient collection of the refined gold.

Advantages of Using a Fully Automatic Gold Refining Machine

The benefits of using a fully automatic gold refining machine are numerous. It offers improvements over manual methods in several areas, including efficiency, safety, and environmental sustainability.

Enhanced Efficiency and Precision

Traditional gold refining methods are labor-intensive and time-consuming, often requiring multiple steps to achieve a high level of purity. In contrast, a fully automatic machine can complete the process in a fraction of the time while ensuring greater accuracy and consistency. The automation of the system means that every step is carried out with precision, resulting in higher yields of pure gold.

Safety Benefits

Refining gold manually involves exposure to hazardous chemicals, high temperatures, and other risks. With a fully automatic gold refining machine, these dangers are minimized, as the machine is designed to operate within controlled environments. This reduces the need for direct human interaction with dangerous materials, thereby increasing overall safety in the refining process.

Environmentally Friendly

Many traditional gold refining techniques have a negative environmental impact due to the use of toxic chemicals and inefficient waste management. A fully automatic gold refining machine is designed to minimize these effects by using cleaner and safer methods. The closed-loop systems in these machines help prevent the release of harmful chemicals into the environment, making them a more eco-friendly choice for gold refining.

Applications of Fully Automatic Gold Refining Machines

Fully automatic gold refining machines are used in various industries where the purification of gold is essential. Their versatility and precision make them suitable for many applications.

Jewelry Industry

Jewelry manufacturers and retailers use fully automatic gold refining machines to purify gold recovered from scrap jewelry and manufacturing waste. These machines enable jewelers to reuse gold by refining it to a level of purity suitable for crafting high-quality jewelry.

Electronic Waste Recycling

The rise of electronic waste (e-waste) has created a need for efficient gold recovery methods. Electronic devices often contain small amounts of gold, which can be recovered and refined using a fully automatic gold refining machine. This allows for the recycling of precious metals from discarded electronics, reducing the need for mining new gold.

Industrial Gold Refining

In large-scale industrial operations, a fully automatic gold refining machine offers the ability to refine large quantities of gold quickly and accurately. This is especially beneficial for gold mining companies and other large entities that require high-purity gold for various industrial purposes, such as in electronics or aerospace.

Choosing the Right Fully Automatic Gold Refining Machine

When selecting a fully automatic gold refining machine, several factors must be considered to ensure it meets your specific refining needs.

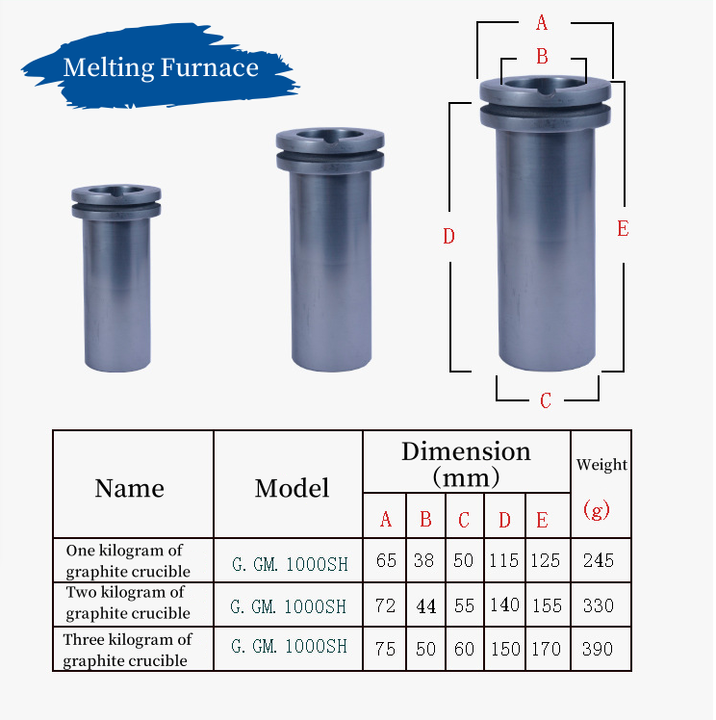

Capacity

The capacity of the machine refers to the amount of gold it can refine in a single batch. Machines designed for large-scale industrial use have higher capacities than those meant for smaller operations. It is essential to choose a machine with a capacity that matches your production needs.

Refining Method

Some fully automatic gold refining machines use chemical methods, while others rely on electrolytic processes. The choice of method depends on factors such as the type of raw material being refined, the desired level of purity, and the cost of operation. Electrolytic methods tend to be more efficient for producing high-purity gold.

Maintenance and Support

Even the most advanced machines require regular maintenance to ensure they continue to operate effectively. It is important to choose a manufacturer or supplier that offers comprehensive support services, including maintenance, repairs, and troubleshooting. A well-maintained machine will provide long-lasting, reliable performance.

A fully automatic gold refining machine is an essential tool for anyone involved in the refining of gold. Its efficiency, precision, and safety make it a superior alternative to traditional refining methods. Whether you are refining gold for jewelry, industrial purposes, or recycling electronic waste, these machines offer a reliable and environmentally friendly solution. By automating the refining process, fully automatic gold refining machines not only save time and labor but also help businesses improve the quality of their refined gold products.