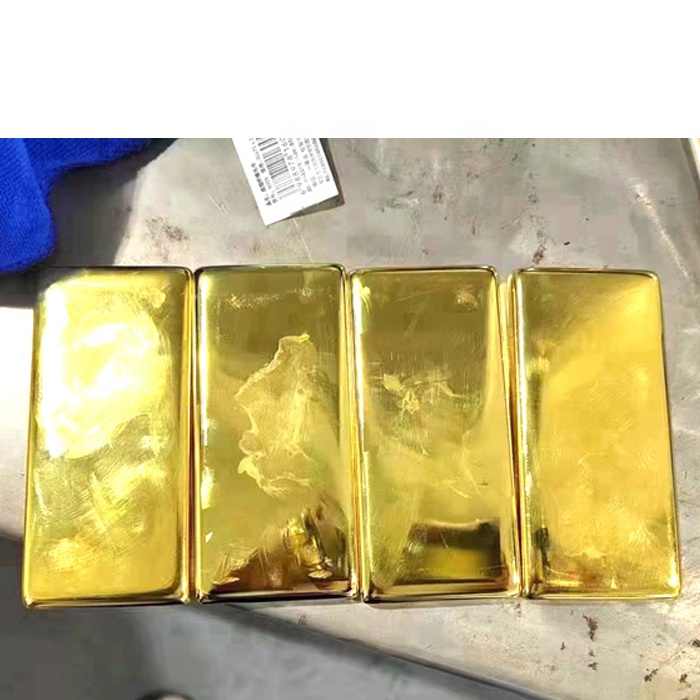

Gold Before Refining And After

Understanding Gold Before Refining and After

Gold Before Refining: Its Natural State

Gold, in its natural state, is a precious metal that occurs in various forms within the earth. This unrefined form, often referred to as raw gold, can be found as nuggets, flakes, or even microscopic particles embedded in rocks. Raw gold is typically alloyed with other metals such as silver, copper, platinum, and palladium, which affects its color and hardness. Understanding the characteristics of gold before refining is crucial for miners and prospectors who aim to extract and process this valuable resource efficiently.

In mining operations, the extraction process begins by crushing and grinding the ore to liberate the gold particles. Specialized machinery from FRT Machinery, designed for this purpose, ensures that the ore is reduced to a fine consistency, allowing for easier separation of gold from waste materials. Following this step, techniques such as flotation, gravity concentration, or cyanidation are employed to concentrate the gold content further.

Benefits of Refining Gold Before Use

The process of refining gold transforms it from a raw, impure state into a high-purity metal suitable for commercial and industrial applications. Refining involves several steps, including smelting, electrolysis, and chemical treatments, which remove impurities and increase the gold’s purity level significantly. For instance, smelting involves heating the raw gold to a molten state and adding fluxes to separate the gold from other metals and impurities. This molten gold is then poured into molds to solidify.

Electrolysis is another key method used in the refining process. During electrolysis, the gold is dissolved in an electrolyte solution, and pure gold is deposited on a cathode while impurities settle at the bottom of the tank. This process is particularly effective in achieving very high levels of purity, essential for applications requiring 99.99% pure gold.

Equipment Used in the Refining Process

FRT Machinery offers a range of equipment designed specifically for refining gold. These machines are engineered to handle the rigorous demands of processing raw gold and achieving the highest standards of purity. One such piece of equipment is the electrorefining cell, which plays a critical role in the final stages of gold purification. The electrorefining cell uses electrical current to strip impurities from the gold, leaving behind a product that is nearly free of contaminants.

Another important piece of equipment is the induction furnace, which is used during the smelting phase. Induction furnaces provide precise temperature control, ensuring that the gold reaches the correct melting point without overheating. This controlled heating process helps maintain the quality of the gold throughout the refining process.

Environmental Impact and Sustainable Practices

While the refining of gold is essential for producing a valuable commodity, it is also important to consider the environmental impact of these processes. Many traditional refining methods involve the use of chemicals like cyanide and mercury, which can be harmful if not handled properly. FRT Machinery advocates for sustainable practices that minimize the environmental footprint of gold refining operations.

One approach to sustainability is the use of alternative chemicals that are less toxic and more environmentally friendly. Additionally, recycling and reusing water in the refining process can help conserve resources and reduce pollution. FRT Machinery has developed systems that incorporate these sustainable practices, making it possible to refine gold with minimal environmental impact.

Conclusion: The Value of Refined Gold

From its raw form deep within the earth to the polished bars and coins we see in banks and jewelry stores, gold undergoes a remarkable transformation through the refining process. The end result is a precious metal that not only holds significant monetary value but also plays a vital role in many industries, from electronics to aerospace. By investing in efficient and sustainable refining technologies, manufacturers can ensure that this valuable resource continues to be available for generations to come.