Gold Electro Refining

Understanding Gold Electro Refining: A Comprehensive Guide

Gold electro refining is a sophisticated process utilized to purify gold by removing impurities through electrolysis. This method is widely adopted due to its efficiency and effectiveness in achieving high purity levels. As experts in the field, FRT Machinery offers state-of-the-art solutions designed specifically for this process, ensuring optimal results every time.

Gold Electro Refining Process

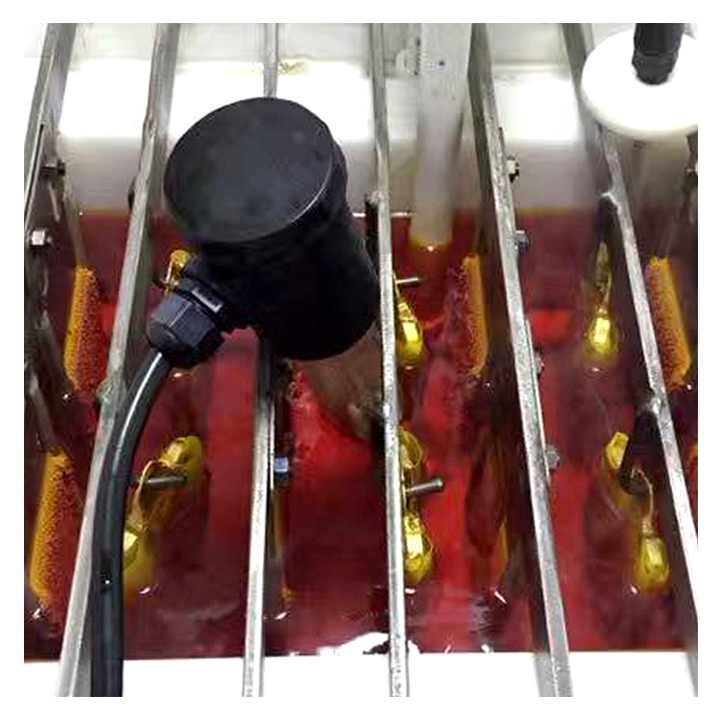

The gold electro refining process begins with the preparation of anode blocks, which consist of impure gold. These anodes are then immersed in an electrolyte solution, typically composed of hydrochloric acid and sodium chloride. During the electrolysis phase, pure gold is deposited on the cathode while impurities either remain in the solution or settle at the bottom of the cell as sludge. This selective deposition is key to achieving the desired purity level.

Benefits of Gold Electro Refining

One of the primary benefits of gold electro refining is its ability to produce gold with a purity level of up to 99.99%. This level of purity is essential for various applications, including jewelry making, electronics, and investment-grade bullion. Additionally, the process is environmentally friendly compared to traditional smelting methods, as it generates minimal waste and reduces harmful emissions.

Equipment Used in Gold Electro Refining

FRT Machinery specializes in providing top-tier equipment for gold electro refining. Our lineup includes electrolysis cells, rectifiers, and automation systems designed to enhance efficiency and reduce operational costs. Each piece of equipment is meticulously engineered to withstand harsh conditions while maintaining high performance standards.

Operational Considerations in Gold Electro Refining

For successful gold electro refining, several factors must be carefully controlled. These include the concentration of the electrolyte, temperature, and current density. Monitoring these parameters ensures consistent quality and prevents potential issues such as uneven deposition or corrosion. FRT Machinery’s advanced monitoring systems provide real-time data, enabling operators to make informed decisions quickly.

Maintenance Practices for Gold Electro Refining Equipment

Regular maintenance is crucial for prolonging the lifespan of gold electro refining equipment. FRT Machinery recommends a comprehensive maintenance schedule that includes routine inspections, cleaning of electrodes, and replacement of worn-out parts. By adhering to these guidelines, facilities can minimize downtime and maintain optimal performance levels.

Future Trends in Gold Electro Refining Technology

As technology advances, so does the field of gold electro refining. Innovations like smart sensors and AI-driven analytics are being integrated into existing systems to further improve efficiency and sustainability. FRT Machinery remains at the forefront of these developments, continuously updating our product line to meet the evolving needs of the industry.

Sustainability in Gold Electro Refining

Environmental sustainability has become a critical aspect of industrial processes worldwide. In gold electro refining, efforts are focused on reducing energy consumption and minimizing chemical waste. FRT Machinery supports these initiatives by designing equipment that operates at lower power requirements and facilitates easier recycling of electrolytes.

By embracing modern techniques and equipment from FRT Machinery, industries engaged in gold electro refining can achieve unparalleled purity levels while contributing positively to environmental conservation efforts.