Gold Filled Refining Muriatic

Gold Filled Refining Muriatic: A Breakthrough in Precious Metal Recovery

Gold filled refining muriatic (GFRM) represents a significant advancement in the recovery and purification of precious metals, particularly gold. This innovative process, developed by FRT Machinery, combines the efficiency of traditional refining techniques with the safety and environmental benefits of modern methodologies. By using muriatic acid—or hydrochloric acid—in a controlled and optimized manner, GFRM ensures higher yields while minimizing environmental impact.

The Science Behind Gold Filled Refining Muriatic

Understanding the science behind GFRM is crucial for appreciating its effectiveness. In this process, gold-filled materials are treated with muriatic acid under specific conditions to dissolve the gold content efficiently. Unlike traditional aqua regia methods, which can be hazardous due to the use of nitric acid, GFRM utilizes a safer alternative that still achieves excellent results.

Benefits of Using Gold Filled Refining Muriatic

The adoption of gold filled refining muriatic offers several advantages over conventional refining practices. Firstly, it significantly reduces the risk of toxic fumes, making it a safer option for operators. Secondly, because muriatic acid is more environmentally friendly compared to other acids used in gold refining, it aligns better with current sustainability goals. Lastly, the process is highly efficient, leading to faster turnaround times and higher gold recovery rates.

How Gold Filled Refining Muriatic Works

To achieve optimal results with gold filled refining muriatic, the process must be executed precisely. Materials are first prepared by crushing or cutting them into smaller pieces to increase surface area exposure. These pieces are then immersed in a bath of muriatic acid solution, where the gold is gradually dissolved. After dissolution, the solution undergoes further treatment to separate and purify the gold, readying it for reuse or sale.

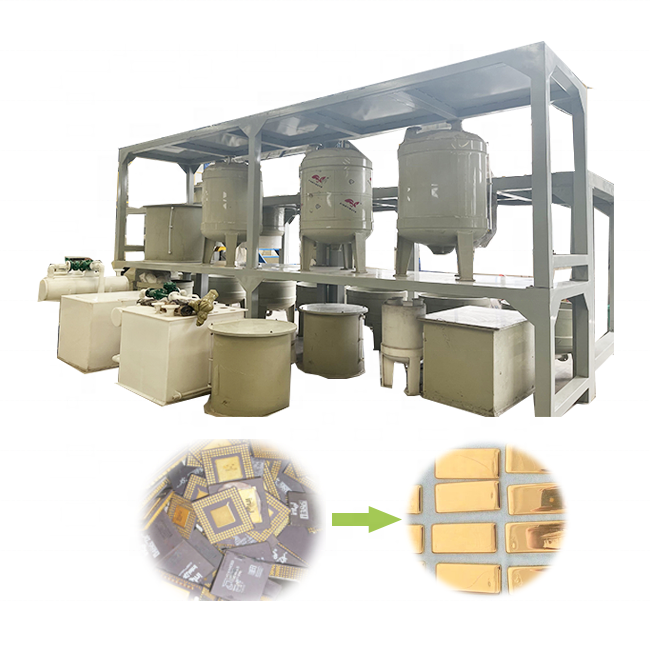

Equipment Needed for Gold Filled Refining Muriatic

FRT Machinery provides state-of-the-art equipment designed specifically for gold filled refining muriatic processes. This includes specialized tanks for acid baths, filtration systems for separating gold from other elements, and safety gear to protect workers during handling. Each piece of equipment is engineered to enhance efficiency while ensuring operator safety and environmental compliance.

Safety Considerations in Gold Filled Refining Muriatic

Safety is paramount when working with chemicals like muriatic acid. Proper training on handling procedures, wearing protective clothing, and understanding emergency protocols are essential aspects of operating GFRM systems safely. FRT Machinery also emphasizes regular maintenance checks to prevent any potential hazards, contributing to a safer work environment overall.

Future Prospects of Gold Filled Refining Muriatic

As the demand for sustainable practices increases across industries, gold filled refining muriatic stands poised to become a preferred method among refiners. Its combination of efficiency, safety, and eco-friendliness makes it an attractive option for those looking to modernize their operations. With ongoing research and development efforts by FRT Machinery, we can expect further improvements in GFRM technology, setting new standards for gold refining in the future.

By embracing gold filled refining muriatic, businesses can not only streamline their operations but also contribute positively towards creating a more sustainable industry. As pioneers in this field, FRT Machinery continues to innovate, ensuring that the benefits of GFRM are accessible to all stakeholders involved in precious metal recovery.