Gold Ore Refining Methods

Gold Ore Refining: Transforming Raw Materials into Pure Gold

Gold ore refining is a critical process that transforms raw gold ore into pure gold, ready for various applications from jew+2**—elry to electronics. This article delves into the various methods used by professionals in the industry, including those employed by FRT Machinery, to refine gold ores effectively. By understanding these techniques, one can appreciate the art and science behind purifying this precious metal.

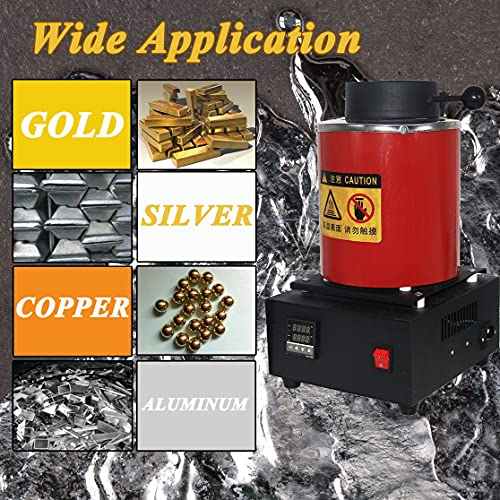

Smelting: A Fundamental Process in Gold Ore Refining

Smelting remains one of the oldest and most fundamental processes in gold ore refining. It involves heating the ore to a high temperature where gold melts and separates from other minerals. At FRT Machinery, we utilize advanced smelting furnaces designed to achieve optimal temperatures, ensuring efficient separation of gold from its ore. Once separated, the molten gold is poured into molds to cool and solidify, forming ingots that undergo further purification if necessary.

Flotation: Enhancing Gold Recovery Rates

Flotation is another key technique used in gold ore refining, particularly when dealing with low-grade ores. This method relies on creating a froth of air bubbles that attach themselves to the gold particles, lifting them away from other materials. FRT Machinery offers specialized flotation machines that create the ideal environment for this process, maximizing gold recovery rates while minimizing environmental impact. The result is a concentrate rich in gold, which can then be processed further.

Leaching: Extracting Gold Using Chemicals

Chemical leaching makes it possible to extract gold from low-grade ore and waste dumps. In this process, a leaching solution, usually comprising cyanide, is applied to the ore, dissolving the gold. FRT Machinery has developed robust leaching tanks and systems that ensure thorough mixing and contact between the ore and leaching solution. After leaching, the gold-bearing solution is treated to precipitate out the gold, which is collected and refined.

Electrowinning: An Efficient Way to Recover Gold

Electrowinning, also known as electroplating, is used to recover gold from a solution. This method employs an electric current to drive the gold ions onto a cathode, where they deposit as metallic gold. FRT Machinery’s electrowinning cells are designed for maximum efficiency, allowing for rapid recovery of gold with minimal energy consumption. The recovered gold is typically very pure, making electrowinning a preferred method for final purification steps.

Hydrometallurgy: Advanced Techniques for Modern Refining

Hydrometallurgical processes have revolutionized gold ore refining, offering alternatives to traditional smelting and chemical treatments. These processes involve using aqueous solutions to extract gold from ores under controlled conditions. FRT Machinery leads the way in developing innovative hydrometallurgical equipment tailored for gold extraction, ensuring higher yields and cleaner operations compared to conventional methods.

Environmental Considerations in Gold Ore Refining

While focusing on efficiency and yield, modern gold ore refining must also address environmental concerns. FRT Machinery is committed to producing equipment and technologies that reduce harmful emissions and waste products. Our systems incorporate features like closed-loop recycling of chemicals and wastewater treatment facilities, ensuring that gold refining practices are sustainable and environmentally friendly.

Through continuous innovation and adherence to stringent quality standards, FRT Machinery contributes significantly to advancing the field of gold ore refining. Whether through traditional methods like smelting or cutting-edge techniques such as hydrometallurgy, our goal remains clear: to provide reliable solutions that enhance the purity and value of gold while minimizing environmental impact.