Gold Ore Smelting Flux

Understanding Gold Ore Smelting Flux: Enhancing Gold Recovery Rates

Gold ore smelting flux plays a pivotal role in the metallurgical process, specifically designed to purify gold from its ore. This essential component helps in separating the precious metal from impurities, thereby enhancing the efficiency and effectiveness of smelting operations. As experts in the field, FRT Machinery recognizes the importance of using high-quality fluxes to achieve optimal results.

Importance of Gold Ore Smelting Flux in Metallurgy

In the context of gold smelting, flux serves to reduce the melting point of the material being processed. It also aids in creating a slag layer that floats on top of the molten metal, effectively trapping impurities and allowing for their removal. By employing the right type of flux, smelters can significantly improve the purity of the final product, making it a critical aspect of gold processing.

Types of Flux Used in Gold Ore Smelting

Several types of fluxes are utilized in gold smelting, each offering unique benefits depending on the specific requirements of the operation. Commonly used fluxes include silica, lime, and soda ash. These materials help in lowering the melting point of the charge and improving the fluidity of the slag, which is crucial for efficient separation.

Benefits of Using Appropriate Gold Ore Smelting Flux

The selection of the correct flux can have a substantial impact on the overall efficiency and economic viability of a smelting operation. Proper flux usage can lead to higher recovery rates of gold, reduced energy consumption, and minimized environmental impact. Additionally, it ensures that the smelting process operates smoothly, reducing downtime and maintenance costs associated with slag build-up or other operational issues.

Factors Influencing the Choice of Gold Ore Smelting Flux

Choosing the most suitable flux for gold smelting depends on several factors, including the composition of the ore, the desired purity level of the gold, and the specific smelting technology employed. FRT Machinery advises considering these variables carefully to ensure that the chosen flux aligns with the operational goals and constraints of your facility.

Techniques for Applying Gold Ore Smelting Flux Effectively

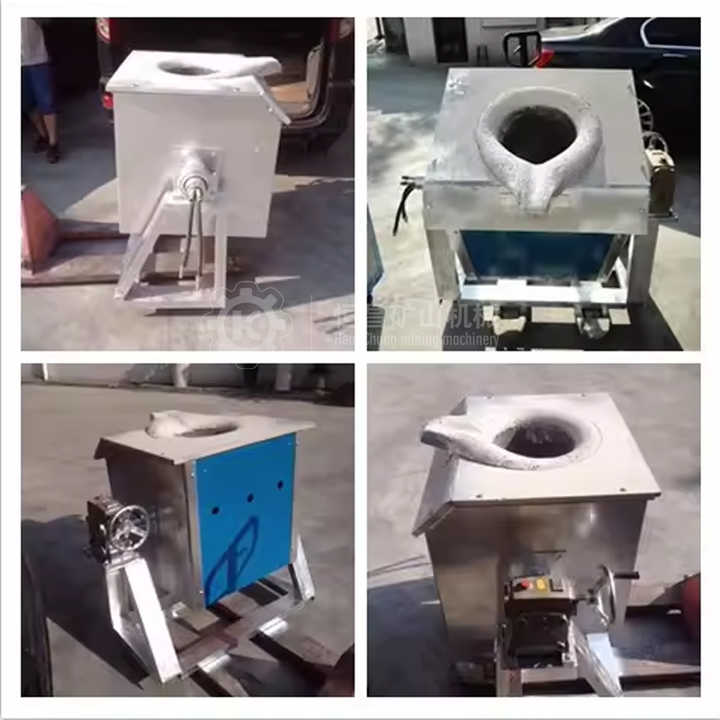

To maximize the benefits of using flux during gold smelting, it is essential to apply it correctly. Techniques such as preheating the flux and adjusting the ratio of flux to ore based on the specific batch characteristics can greatly enhance the smelting process. FRT Machinery offers advanced solutions designed to optimize these applications, ensuring that every step of the smelting process is carried out efficiently.

Conclusion: The Role of FRT Machinery in Advancing Gold Ore Smelting Flux Technology

At FRT Machinery, we are committed to advancing the technology behind gold ore smelting fluxes. Our innovative approaches and deep understanding of metallurgical processes enable us to provide solutions that not only improve the quality of the end product but also contribute to more sustainable and cost-effective mining practices. Whether you’re looking to upgrade your existing smelting setup or require expert consultation on optimizing your flux usage, FRT Machinery stands ready to support your endeavors.