Gold Ore Smelting Furnace

Understanding the Gold Ore Smelting Furnace by FRT Machinery

The Fundamentals of a Gold Ore Smelting Furnace

Gold ore smelting furnaces are essential in the extraction of gold from its ore. These furnaces employ high temperatures to separate gold from impurities, ensuring the purity of the final product. In modern mining operations, the efficiency and effectiveness of a gold ore smelting furnace can significantly impact production costs and environmental impact.

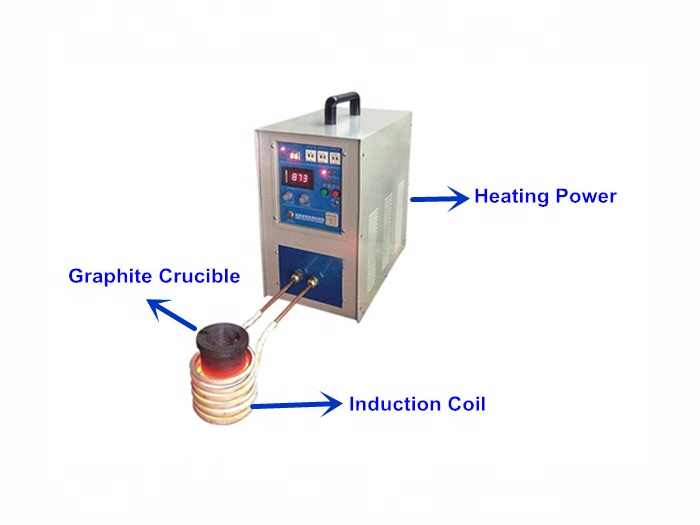

Key Components of a Gold Ore Smelting Furnace

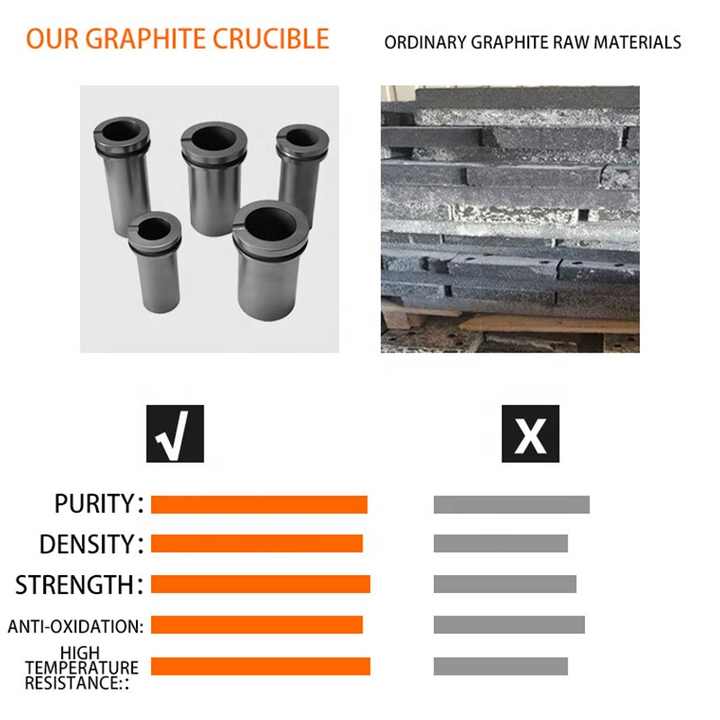

A gold ore smelting furnace consists of several critical components designed to facilitate the smelting process. The primary parts include the crucible, heating elements, and insulation materials. The crucible, typically made from refractory materials, holds the gold ore during the smelting process. Heating elements generate the necessary temperatures, while insulation helps maintain these temperatures efficiently, reducing energy consumption.

Advantages of Using a Gold Ore Smelting Furnace by FRT Machinery

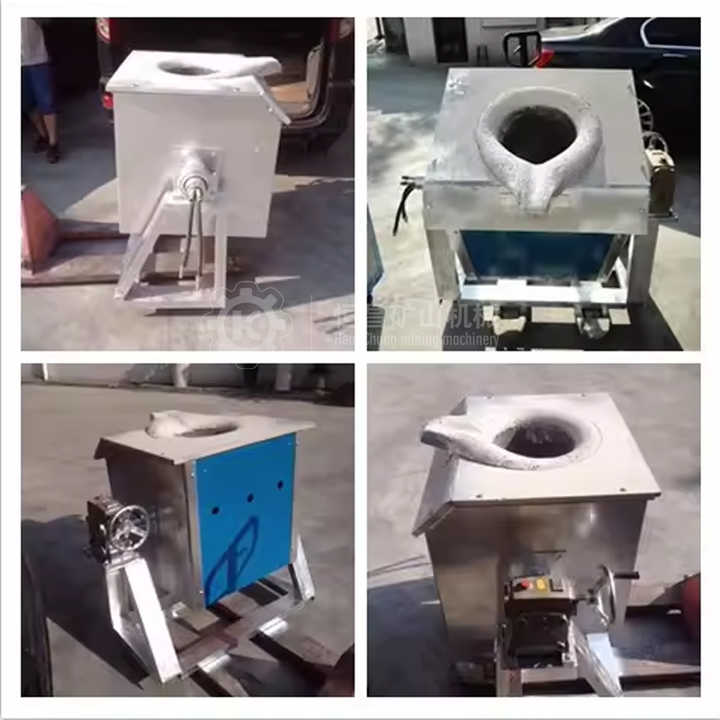

FRT Machinery’s gold ore smelting furnaces offer numerous advantages over traditional methods. Firstly, they achieve higher gold recovery rates due to their advanced design and precise temperature control. Secondly, these furnaces minimize the emission of harmful gases, contributing to a more sustainable mining industry. Lastly, their compact design allows for easy integration into existing setups, enhancing operational flexibility.

Operating a Gold Ore Smelting Furnace Safely and Efficiently

Safety and efficiency are paramount when operating a gold ore smelting furnace. Regular maintenance checks ensure that all components function optimally, preventing potential hazards. Additionally, operators must be trained in handling high-temperature environments and understand the importance of using protective gear. For optimal efficiency, maintaining a consistent feed rate and monitoring temperature settings closely are crucial practices.

Environmental Impact of Gold Ore Smelting Furnaces

Environmental considerations play a significant role in the design and operation of gold ore smelting furnaces. Modern furnaces like those manufactured by FRT Machinery incorporate features aimed at reducing emissions and improving energy efficiency. This includes advanced filtration systems to capture particulates and gases released during the smelting process, thereby minimizing the environmental footprint.

Choosing the Right Gold Ore Smelting Furnace for Your Needs

Selecting the appropriate gold ore smelting furnace depends on various factors such as the scale of operations, specific requirements regarding gold purity, and budget constraints. FRT Machinery offers a range of furnaces tailored to meet different needs, from small-scale artisanal mining to large industrial applications. Consulting with experts from FRT Machinery ensures that you choose a furnace that best suits your requirements, enhancing productivity and profitability.

Future Innovations in Gold Ore Smelting Furnace Technology

As technology advances, so does the design and functionality of gold ore smelting furnaces. FRT Machinery is committed to researching and developing new technologies that further improve the efficiency and sustainability of smelting processes. This includes exploring alternative energy sources for heating elements and refining methods to extract even higher purity gold with minimal environmental impact. Stay tuned for updates on how FRT Machinery continues to shape the future of gold ore smelting.