Details

- Home

- gold purification electrolysis

gold purification electrolysis

Table of Contents

ToggleGold Purification Electrolysis A Modern Refining Technique

Gold purification is an essential process in the refining of raw gold ore into high-quality, usable gold. Among the many techniques used in the modern era, gold purification electrolysis stands out as one of the most efficient and effective. This method utilizes an electric current to remove impurities from the raw gold, resulting in an exceptionally pure product. In this article, we will explore the details of gold purification through electrolysis, its benefits, and its applications across various industries.

What is Gold Purification Electrolysis?

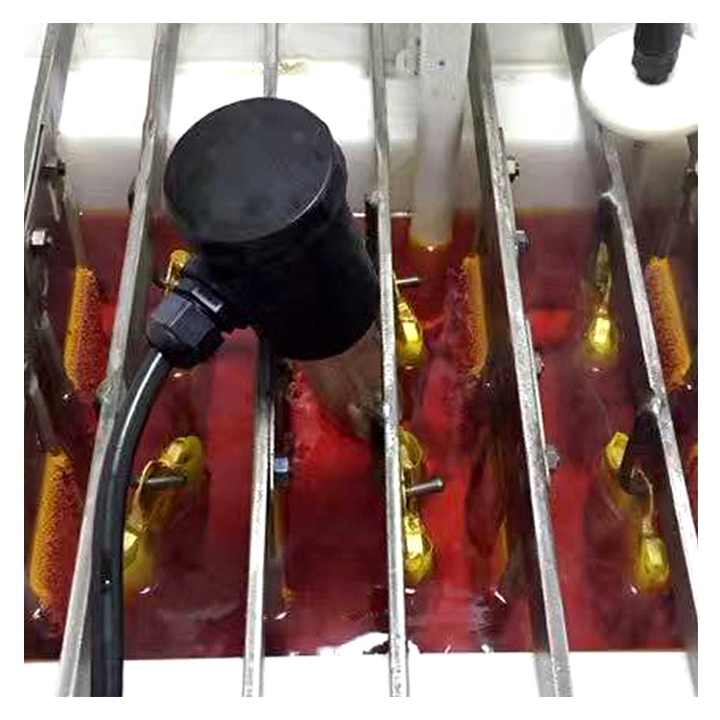

Electrolysis is a process that involves passing an electric current through a solution to separate and purify substances. When applied to gold purification, it refers to the use of electrochemical methods to remove impurities and isolate pure gold. This is done by submerging the impure gold in an electrolyte solution and using an electrical charge to encourage gold ions to deposit on an electrode as purified gold.

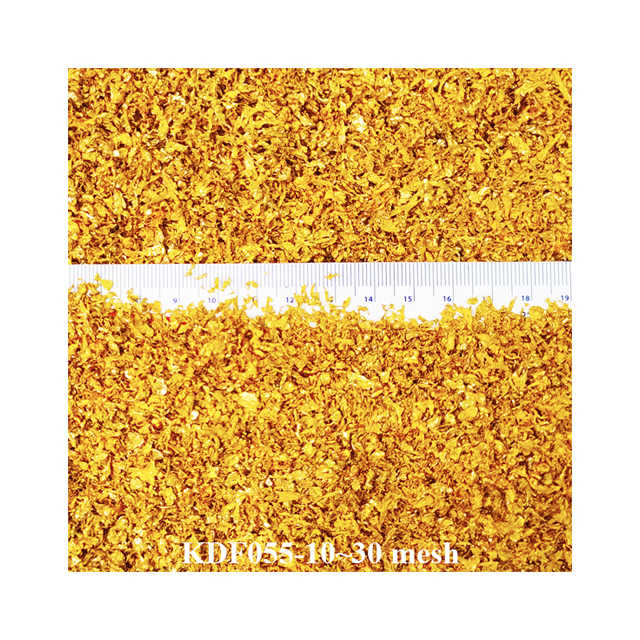

The gold purification electrolysis process is commonly used in industrial settings, particularly in gold refineries, to achieve very high levels of gold purity. This method can refine gold to a purity of 99.99%, making it suitable for a variety of high-end applications.

The Process of Gold Purification Electrolysis

The gold purification electrolysis process can be broken down into several key steps:

Dissolving the Gold

The first step involves dissolving the impure gold in an electrolyte solution. This solution often contains chemicals like gold chloride or gold cyanide, which break down the gold into ions. The impure gold is used as the anode (positive electrode) in the electrochemical cell, while a thin sheet of pure gold or another conductive material is used as the cathode (negative electrode).

Passing the Electric Current

Once the gold is dissolved in the solution, an electric current is applied. This causes the gold ions from the anode to migrate through the solution toward the cathode. As the gold ions reach the cathode, they are reduced and deposit onto the surface as pure, solid gold. Meanwhile, non-gold impurities are left behind in the solution or form a sludge at the bottom of the cell.

Collecting the Pure Gold

After a sufficient amount of time has passed, the cathode is removed from the electrolyte solution, and the pure gold deposited on it is collected. This gold is then further processed, typically by melting it down and casting it into bars or other desired forms. The result is highly purified gold that meets the strict standards required for commercial use.

Benefits of Gold Purification Electrolysis

Gold purification electrolysis offers several distinct advantages over other refining techniques, making it the preferred method for many refineries.

Exceptional Purity Levels

Electrolysis can produce gold with a purity level as high as 99.99%. This makes it ideal for industries that require extremely pure gold, such as electronics, jewelry, and investment-grade bullion production.

Environmentally Friendly

Compared to traditional smelting methods, electrolysis is more environmentally friendly. The use of electric current instead of intense heat reduces emissions, and the controlled use of chemicals minimizes hazardous waste. This makes it a more sustainable choice for gold refining.

Precision and Control

Electrolysis provides precise control over the refining process, allowing refiners to adjust parameters like voltage and electrolyte concentration to achieve the desired purity. This precision results in less waste and more efficient refining.

Cost-Effective

Despite its sophistication, the electrolysis process is cost-effective, especially when refining large quantities of gold. The method’s efficiency reduces operational costs, making it a favorable option for refineries that require both high output and high quality.

Applications of Gold Purification Electrolysis

The gold purification electrolysis process is used in several industries where high-purity gold is essential.

Electronics Manufacturing

Gold is widely used in the electronics industry because of its excellent conductivity and resistance to corrosion. For these applications, the highest levels of purity are necessary to ensure the reliability and efficiency of electronic components like connectors, circuit boards, and semiconductors. Gold purified through electrolysis meets these stringent requirements.

Jewelry Production

In the jewelry industry, the aesthetic and material quality of gold is paramount. Gold purification electrolysis ensures that the gold used in luxury jewelry is free from impurities, giving it a brighter shine and enhanced durability. This pure gold is then alloyed with other metals to create pieces with varying karat levels, depending on the design and customer demand.

Bullion and Coinage

Many gold coins and bars intended for investment purposes are produced using electrolysis-refined gold. Investors and financial institutions demand the highest purity levels for these assets, and gold purification electrolysis ensures that the gold meets the international standards required for trade and storage.

Medical and Dental Applications

Gold’s biocompatibility makes it a popular material in the medical field, particularly for dental restorations and implants. Gold purified through electrolysis is free of contaminants that could cause adverse reactions, making it a safe and durable choice for medical devices.

Gold purification electrolysis is a highly effective method for refining gold to the highest levels of purity. By utilizing an electric current to separate impurities, this technique produces gold that meets the rigorous standards of industries ranging from electronics and jewelry to bullion and medical applications. The process offers numerous advantages, including environmental sustainability, precision, and cost-effectiveness, ensuring that it remains a crucial part of modern gold refining.

As the demand for pure gold continues to grow across various sectors, gold purification electrolysis will remain at the forefront of refining technology, providing a reliable and efficient means of achieving gold purity.