gold purification machine in india

Understanding Gold Purification Machines in India

Gold purification is a crucial process in the gold industry, ensuring that gold reaches the highest levels of purity for various applications such as jewelry, investment, and industrial use. In India, a country with a rich history of gold consumption and trade, the demand for efficient gold purification machines has grown significantly. This article explores the importance of gold purification machines in India, how they work, and their impact on the gold market.

The Importance of Gold Purification in India

India is one of the largest consumers of gold in the world, with gold being an essential part of Indian culture, particularly in weddings and religious ceremonies. As the demand for high-quality gold increases, so does the need for efficient gold purification methods. The use of gold purification machines has become vital in ensuring that gold meets the stringent purity standards required in the global market.

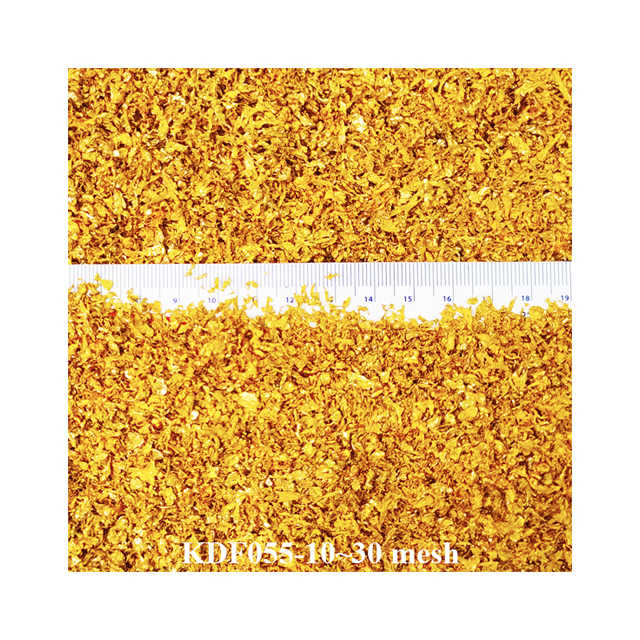

Gold purification machines help extract impurities from raw gold, ensuring the final product is pure and ready for sale or further processing. These machines are used by jewelers, gold refiners, and mining companies to produce gold with a high degree of purity, often reaching 99.99%. The machines play a pivotal role in the overall quality of gold products and help maintain India’s position in the global gold market.

How Gold Purification Machines Work

Gold purification machines operate using various techniques to remove impurities from raw gold. These machines are designed to automate the process, making it more efficient and cost-effective. Some of the common methods used in gold purification machines include:

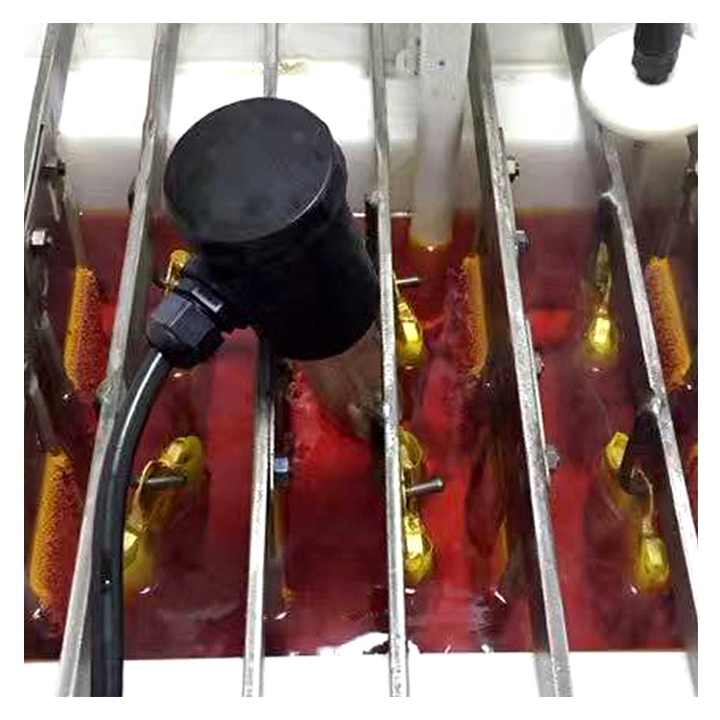

1. Electrolysis Process

One of the most common methods for gold purification is the electrolysis process. In this method, raw gold is dissolved in a solution, and an electric current is passed through it. This causes the pure gold to deposit onto a cathode, separating it from impurities. Electrolysis is a highly efficient process and is often used in gold purification machines to achieve high levels of purity.

2. Chemical Refining

Some gold purification machines use chemical refining, which involves dissolving the gold in acids such as aqua regia. The impurities are then filtered out, and the gold is precipitated from the solution. This method is widely used in smaller-scale operations and laboratories due to its effectiveness in refining gold to high purity levels.

3. Miller Process

The Miller process involves blowing chlorine gas through molten gold. The chlorine reacts with the impurities, forming chlorides that float to the surface and can be skimmed off. This method is commonly used in gold purification machines in India to achieve 99.5% purity.

Types of Gold Purification Machines in India

India has a variety of gold purification machines that cater to different scales of operation. From small-scale refiners to large gold processing plants, there are machines available to suit various needs. Some of the most common types of gold purification machines in India include:

1. Small-Scale Purification Machines

These machines are designed for smaller operations, such as local jewelers or small refineries. They are compact, easy to use, and capable of purifying gold in smaller quantities. Small-scale machines are ideal for businesses that need high-quality gold for jewelry production or investment purposes but don’t operate on a large scale.

2. Industrial-Scale Machines

Industrial-scale gold purification machines are used by large refineries and gold processing plants. These machines are capable of handling large quantities of gold and can purify it to the highest standards required by the global market. Industrial-scale machines often incorporate advanced technologies, such as continuous electrolysis and chemical refining, to ensure maximum efficiency and purity.

3. Portable Purification Machines

Portable gold purification machines are becoming increasingly popular in India, especially for small refineries and mining operations. These machines are easy to transport and can be used on-site, making them ideal for operations in remote areas. They are typically used in conjunction with other purification methods to refine gold extracted from mining operations.

Gold Purification Machines and India’s Gold Market

Gold purification machines have a significant impact on India’s gold market. By ensuring that gold meets global purity standards, these machines help Indian gold refineries and jewelers compete in the international market. Purified gold is highly sought after in countries like China, the United States, and the Middle East, where it is used for a variety of purposes, including jewelry, electronics, and investment.

The availability of gold purification machines in India has also helped local businesses improve the quality of their products. Small jewelers and refiners can now produce gold with a higher degree of purity, allowing them to charge a premium for their products. This has helped the Indian gold industry grow and meet the increasing demand for high-quality gold both domestically and internationally.

Challenges in the Gold Purification Industry

While gold purification machines have brought numerous benefits to the Indian gold market, there are still challenges that the industry faces. One of the main challenges is the high cost of gold purification equipment, which can be a barrier for small-scale operators. Additionally, the complexity of the purification process requires skilled labor, which can be difficult to find in certain regions of India.

Another challenge is the environmental impact of gold purification. Some methods, such as chemical refining, use hazardous chemicals that can harm the environment if not properly managed. To address this issue, many companies in India are adopting more environmentally friendly purification methods and investing in equipment that minimizes waste and pollution.

Gold purification machines play a vital role in the Indian gold industry, helping to ensure that gold meets the highest purity standards. From small-scale jewelers to large refineries, these machines are essential for producing gold that is competitive in the global market. While there are challenges, the advancements in purification technology have made it easier for Indian businesses to refine gold efficiently and sustainably. As the demand for high-purity gold continues to rise, the use of gold purification machines in India is set to grow, further strengthening the country’s position in the global gold market.