gold purification machine

The quest for pure gold has driven technological advancements in refining processes, leading to the development of sophisticated tools like the gold purification machine. Whether you are involved in large-scale gold refining or small-scale operations, a gold purification machine can significantly enhance the efficiency and quality of your output. This article explores the benefits, operational guidelines, and maintenance tips for maximizing the use of a gold purification machine.

Understanding the Gold Purification Machine

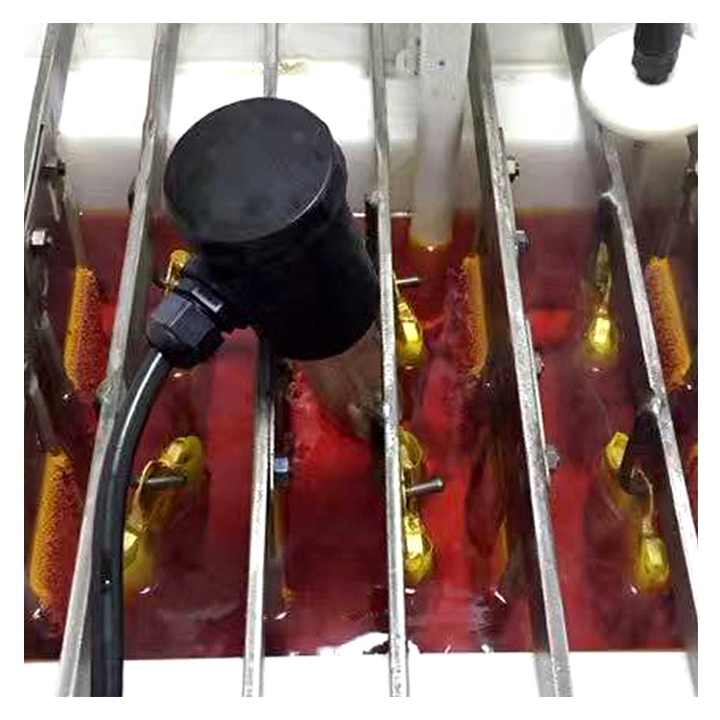

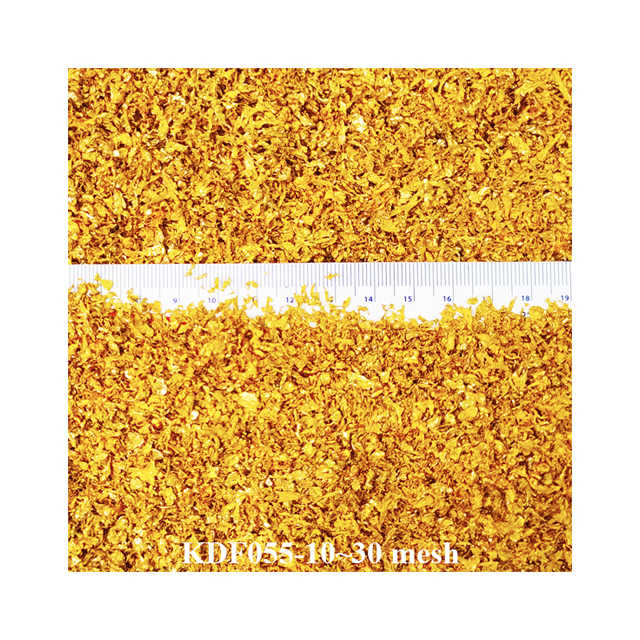

A gold purification machine is a specialized device designed to refine gold by removing impurities and contaminants. These machines use various methods such as electrolysis, aqua regia, and other chemical processes to achieve high levels of gold purity. The primary advantage of using a gold purification machine is its ability to handle large quantities of gold with precision and speed.

Most modern gold purification machines are equipped with automated features, allowing for minimal human intervention and reducing the risk of errors. The efficiency of these machines makes them ideal for both industrial applications and small-scale operations where consistency and quality are paramount.

Advantages of Using a Gold Purification Machine

There are numerous benefits to using a gold purification machine in your refining process. These advantages include:

- High Purity Levels: A gold purification machine can refine gold to purity levels as high as 99.99%, making it suitable for high-value applications such as jewelry and investment products.

- Efficiency: The automation and precision of a gold purification machine allow for faster processing times compared to manual methods. This efficiency translates to higher output and reduced labor costs.

- Safety: Gold purification machines are designed with safety features that minimize exposure to hazardous chemicals and reduce the risk of accidents during the refining process.

- Scalability: Whether you are processing a few grams or several kilograms of gold, a gold purification machine can be scaled to meet your specific needs. This flexibility makes it an invaluable tool for a variety of operations.

How to Choose the Right Gold Purification Machine

Selecting the right gold purification machine requires careful consideration of several factors. Here are some key points to keep in mind:

- Capacity: Determine the volume of gold you plan to process regularly. Machines come in different capacities, so choose one that matches your production needs without overextending your budget.

- Technology: Different gold purification machines use various technologies such as induction heating, chemical baths, or electrolysis. Choose a machine that aligns with your preferred method of purification and provides the desired level of purity.

- Ease of Use: User-friendly machines with intuitive controls can significantly reduce the learning curve, allowing you to achieve optimal results quickly.

- Cost: While the initial investment in a gold purification machine can be substantial, consider the long-term benefits. A more expensive machine may offer better efficiency and durability, providing a higher return on investment.

Operating Your Gold Purification Machine

To achieve the best results from your gold purification machine, it is essential to follow proper operational guidelines. Here is a step-by-step guide:

- Setup: Before starting, ensure that the machine is set up according to the manufacturer’s instructions. This includes proper ventilation, connection to power sources, and preparation of any required chemicals.

- Loading: Carefully load the gold material into the machine. Ensure that the quantity does not exceed the machine’s capacity, as overloading can lead to suboptimal purification and potential damage to the machine.

- Operation: Initiate the purification process as per the machine’s operating manual. Most machines will require you to monitor the process and make adjustments if necessary. Automation features can help maintain consistent results.

- Testing: After the purification cycle is complete, test the gold to confirm that it has reached the desired purity level. If further refinement is needed, the machine may allow for additional cycles.

- Unloading: Once purification is complete, carefully remove the gold from the machine. Handle the purified gold with clean tools to avoid contamination.

Maintenance and Care of Your Gold Purification Machine

Proper maintenance of your gold purification machine is crucial to ensuring its longevity and performance. After each use, clean the machine thoroughly, removing any chemical residues and debris. Regularly inspect the machine’s components for signs of wear and tear, replacing parts as needed.

Additionally, follow the manufacturer’s recommendations for routine maintenance tasks, such as lubricating moving parts or calibrating sensors. Proper storage of the machine in a dry, temperature-controlled environment will also help prevent damage and prolong its lifespan.

Investing in a gold purification machine is a smart choice for anyone serious about achieving high-quality gold refinement. These machines offer unparalleled efficiency, safety, and precision, making them essential tools in the gold refining industry. By choosing the right machine and following best practices for operation and maintenance, you can ensure that your gold purification process is both effective and reliable.