Gold Refining By Fire

Gold Refining by Fire: A Timeless Art Transformed by Modern Technology

Precision in Gold Refining by Fire: The Foundation of Purity

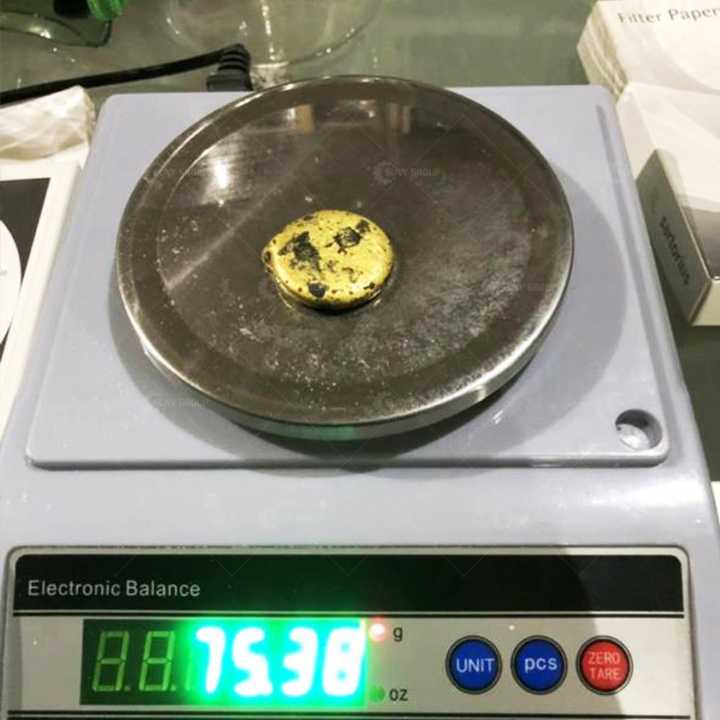

Gold refining by fire, also known as cupellation, has been a cornerstone of metallurgy for millennia. This ancient technique continues to be relevant today, thanks to advancements made by industry leaders such as FRT Machinery. These innovations ensure that the process of separating gold from its impurities is more precise and efficient than ever before. At the heart of this method lies the principle of heating gold ore to high temperatures where base metals oxidize and can be removed, leaving behind pure gold.

Safety Measures in Gold Refining by Fire: Ensuring a Secure Process

Safety is paramount when dealing with the extreme conditions required for gold refining by fire. FRT Machinery’s latest equipment incorporates state-of-the-art safety features designed to protect operators while maintaining operational efficiency. From automated temperature controls to advanced ventilation systems, every aspect of their machinery is crafted with both performance and security in mind. Workers are provided with comprehensive training on handling materials and operating machinery, ensuring that all procedures adhere to the highest standards of occupational health and safety.

Environmental Impact of Gold Refining by Fire: Striving for Sustainability

As awareness grows regarding the environmental impact of industrial processes, companies like FRT Machinery are stepping up efforts to make gold refining by fire more sustainable. By focusing on reducing emissions and waste, they’re setting new benchmarks for eco-friendly practices within the industry. Innovative recycling programs and the use of cleaner fuels contribute significantly towards minimizing the carbon footprint associated with traditional refining methods. This commitment to sustainability not only benefits the planet but also enhances the company’s reputation among environmentally conscious consumers.

Technological Advancements in Gold Refining by Fire: Elevating Efficiency

Modern technology plays a crucial role in enhancing the efficiency of gold refining by fire. FRT Machinery’s cutting-edge solutions offer unparalleled precision and speed, allowing for faster turnaround times without compromising on quality. Advanced sensors and robotics integrated into the refining process enable real-time monitoring and adjustments, ensuring that each batch of gold meets stringent purity standards. Such technological innovations are pivotal in driving the industry forward, making gold refining by fire more accessible and cost-effective for businesses of all sizes.

Economic Benefits of Gold Refining by Fire: Unlocking Value

The economic advantages of gold refining by fire are substantial, particularly when leveraging the latest technologies offered by FRT Machinery. By improving recovery rates and reducing operational costs, businesses can maximize their return on investment. Moreover, the ability to produce higher-grade gold opens up new market opportunities, catering to industries that demand exceptional purity levels. This translates into increased profitability and competitive edge in a global marketplace where quality is king.

Future of Gold Refining by Fire: Innovations on the Horizon

Looking ahead, the future of gold refining by fire seems promising as technological advancements continue to shape the landscape. FRT Machinery remains committed to pushing boundaries through research and development, aiming to introduce even more efficient and sustainable solutions. As the industry evolves, so too will the techniques used for refining precious metals, ensuring that this age-old practice remains relevant well into the future. With ongoing improvements in automation, energy efficiency, and environmental stewardship, the next chapter of gold refining by fire promises to be exciting and transformative.