Gold Refining Fingers Pins Differ

Gold Refining Fingers: Understanding the Basics

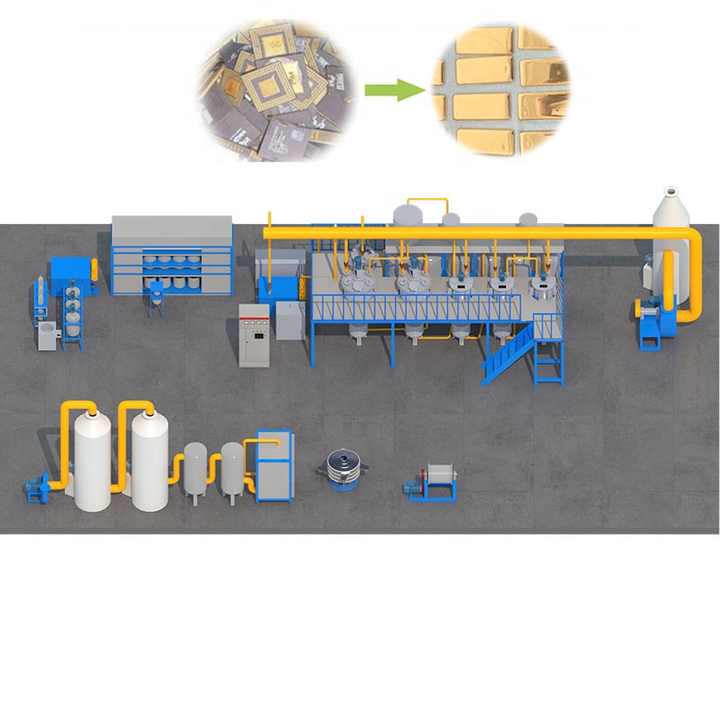

Gold refining fingers (GFR) are specialized components used in electronic waste recycling to extract gold from discarded devices efficiently. As technology advances, so does the need for more precise and effective methods of gold recovery. FRT Machinery, a leading manufacturer in the industry, has been at the forefront of developing innovative solutions for gold refining processes. This article delves into the world of gold refining fingers, highlighting their importance and exploring the differences among various types.

Gold Refining Fingers Pins: Types and Characteristics

Gold refining fingers pins differ significantly based on design, material composition, and intended application. Understanding these variations is crucial for selecting the right type for specific refining needs. For instance, some pins are designed for high-efficiency extraction from circuit boards, while others focus on minimizing environmental impact during the refining process. FRT Machinery offers a range of options tailored to meet diverse customer requirements, ensuring optimal performance across different industrial settings.

Applications of Gold Refining Fingers Pins

The applications of gold refining fingers extend beyond traditional gold mining operations. In modern electronics manufacturing and recycling facilities, these components play a pivotal role in recovering valuable metals from waste streams. By implementing advanced GFR technology, companies can enhance their sustainability practices and contribute positively to circular economy initiatives. FRT Machinery’s innovative designs are particularly effective in environments where space constraints and operational efficiency are key considerations.

Gold Refining Fingers Pins Differ in Efficiency

One of the most critical aspects of gold refining fingers is their efficiency in extracting gold. Different designs and materials affect how effectively these tools can separate gold from other materials. FRT Machinery’s research and development team continuously works on improving the efficiency of their products, focusing on factors such as durability, speed, and purity of the recovered gold. This ongoing innovation ensures that users benefit from state-of-the-art technology capable of maximizing returns on investment.

Maintenance Requirements of Gold Refining Fingers

Like any mechanical equipment, gold refining fingers require regular maintenance to function optimally. However, the specific needs can vary widely depending on the design and operational conditions. FRT Machinery provides comprehensive guidelines and support services to help clients maintain their equipment properly. Regular cleaning, inspection, and replacement of worn parts are essential practices that can significantly extend the lifespan of gold refining fingers, ensuring consistent performance over time.

Environmental Impact of Gold Refining Fingers Pins

Environmental considerations have become increasingly important in all industries, including gold refining. Different types of gold refining fingers pins have varying impacts on the environment. FRT Machinery emphasizes sustainable practices throughout its manufacturing processes and product lifecycle. By choosing eco-friendly materials and designing products that reduce waste, they aim to minimize the ecological footprint of gold refining activities.

Future Trends in Gold Refining Fingers Technology

Looking ahead, the future of gold refining fingers technology promises exciting advancements. Innovations in materials science, automation, and artificial intelligence will likely shape the next generation of GFR solutions. FRT Machinery is committed to staying ahead of these trends, investing heavily in R&D to bring cutting-edge technologies to market. As we move towards a more sustainable and technologically advanced world, the role of efficient gold refining fingers in supporting global economic and environmental goals becomes ever more critical.