Gold Refining For Dummies

Gold Refining for Dummies: A Comprehensive Guide

Gold refining is an essential process in the extraction and purification of gold from raw ore or recycled materials. This guide will walk you through the basics of gold refining, ensuring that by the end, you have a solid understanding of the techniques and equipment used in this intricate process. Whether you’re a hobbyist looking to refine small quantities of gold or a professional interested in large-scale operations, FRT Machinery offers state-of-the-art solutions designed to meet your needs.

Understanding the Basics of Gold Refining

Gold refining involves several steps aimed at purifying gold, removing impurities, and achieving the highest possible purity levels. The first step in any refining process is to ensure that the gold has been extracted from its ore or other base materials. Once isolated, gold undergoes various treatments to remove contaminants like silver, copper, and other metals.Gold refiningtechniques can range from simple methods suitable for home use to complex industrial processes requiring specialized machinery.

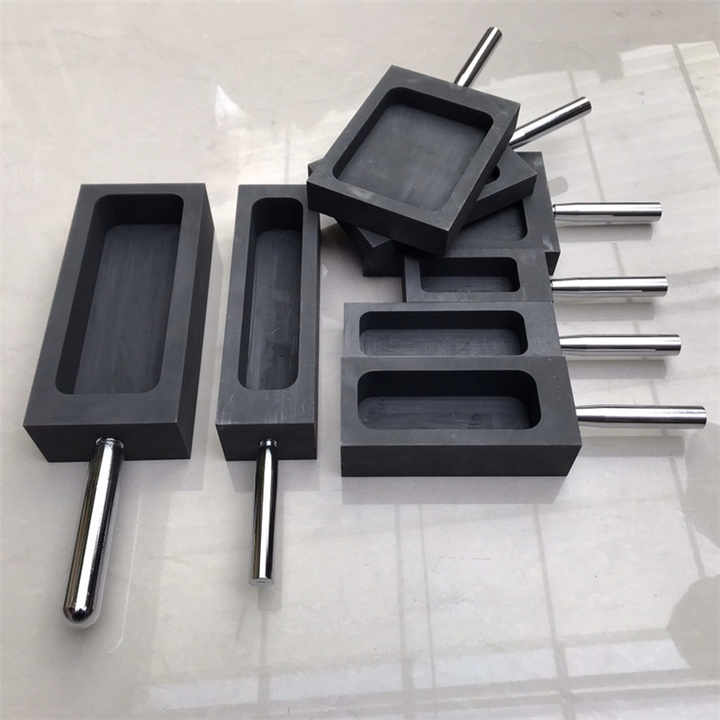

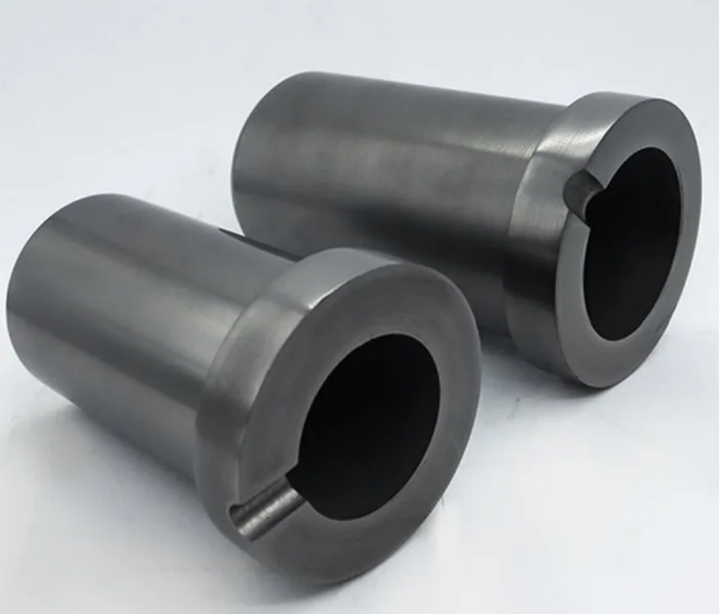

Choosing the Right Equipment for Gold Refining

Selecting appropriate equipment is crucial for efficient gold refining. FRT Machinery provides a wide range of tools and machines tailored for different stages of the refining process. For instance, melting furnaces are essential for converting gold into a liquid form, making it easier to separate from non-metallic impurities. Electrolytic cells, on the other hand, are vital for the final stages of purification, where gold is deposited onto cathodes, leaving behind unwanted elements.Gold refiningequipment must be durable, easy to operate, and capable of handling varying volumes of material.

The Art of Smelting in Gold Refining

Smelting is one of the oldest methods of gold refining, still widely used today due to its effectiveness. During smelting, gold ore is heated to high temperatures in the presence of fluxes that help separate the gold from other minerals. The molten gold sinks to the bottom of the furnace, while slag (a mixture of metal oxides) floats on top, allowing for easy separation. Moderngold refiningpractices often combine traditional smelting techniques with advanced filtration and cooling systems to enhance efficiency and safety.

Electrolysis: A Key Process in Gold Refining

Electrolysis plays a pivotal role in achieving ultra-high purity levels ingold refining. In this process, an electric current is passed through a solution containing dissolved gold, causing the metal to deposit on the cathode while impurities remain in the solution. Electrolytic refining is particularly useful for removing trace amounts of silver, platinum, and other precious metals that cannot be eliminated through simpler methods. FRT Machinery’s electrolysis units are engineered to optimize this process, ensuring maximum recovery rates and minimal environmental impact.

Safety Considerations in Gold Refining

Safety is paramount when dealing with chemicals and high-temperature processes involved ingold refining. Proper protective gear, including gloves, goggles, and respirators, should always be worn. Additionally, all refining activities must comply with local regulations regarding waste disposal and air quality control. FRT Machinery designs its equipment with built-in safety features such as emergency shut-off switches and temperature sensors to prevent accidents and ensure operator well-being.

Environmental Impact and Sustainable Practices in Gold Refining

As awareness grows around the environmental consequences of mining and refining activities, there’s increasing pressure on the industry to adopt more sustainable practices.Gold refiningcompanies are exploring greener alternatives to traditional chemical leaching agents, focusing instead on biological and electrochemical methods that reduce toxic waste. FRT Machinery supports these initiatives by developing innovative technologies that minimize resource consumption and promote recycling within the refining cycle.

By following these guidelines and utilizing reliable equipment from FRT Machinery, anyone can successfully engage ingold refining, whether as a hobby or as part of a larger commercial venture. Remember, patience and precision are key ingredients in mastering the art of gold refining.