Gold Refining Sodium Metabisulfite

Understanding the Role of Sodium Metabisulfite in Gold Refining

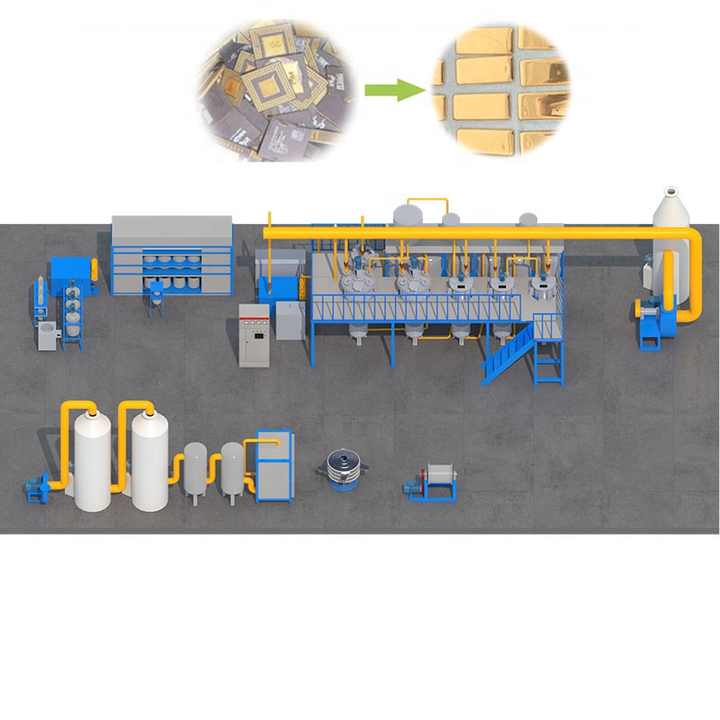

Gold refining is a meticulous process aimed at purifying gold ore to achieve the highest possible purity levels. Among the various chemicals used in this intricate procedure, sodium metabisulfite (SMB) stands out for its unique properties and benefits. FRT Machinery, a leading manufacturer of gold refining equipment, incorporates SMB in several stages of the refining process to enhance efficiency and sustainability.

Benefits of Using Sodium Metabisulfite in Gold Refining

In the context of gold refining, sodium metabisulfite serves multiple purposes. Its primary function is as a reducing agent, which helps in the precipitation of gold from cyanide solutions. This ability makes it a crucial component in the detoxification process, where it effectively breaks down harmful cyanide compounds into less toxic substances. Moreover, SMB is environmentally friendly compared to other alternatives, making it a preferred choice for modern refineries committed to sustainable practices.

How Sodium Metabisulfite Enhances Gold Recovery Rates

The introduction of sodium metabisulfite into the gold refining process can significantly enhance recovery rates. When gold is dissolved using cyanide leaching, the addition of SMB facilitates the precipitation of gold particles out of solution. This process is particularly effective in treating refractory ores, which are often resistant to conventional extraction methods. By optimizing the use of SMB, FRT Machinery’s equipment ensures higher yields and reduced operational costs.

Safety Considerations When Using Sodium Metabisulfite in Refining

While sodium metabisulfite offers numerous advantages, handling it requires adherence to strict safety protocols. As a solid powder, SMB can be hazardous if inhaled or ingested. Therefore, protective gear such as gloves, goggles, and respirators must be worn during its application. FRT Machinery designs its systems with built-in safety features to minimize risks associated with chemical exposure, ensuring a safer working environment for operators.

Environmental Impact of Sodium Metabisulfite in Gold Refining

One of the key reasons for the growing popularity of sodium metabisulfite in gold refining is its lower environmental impact compared to traditional methods. The chemical’s ability to detoxify cyanide solutions without producing harmful by-products aligns well with current trends towards greener industrial practices. FRT Machinery supports these initiatives by integrating SMB into their refining processes, thereby contributing to the reduction of the industry’s ecological footprint.

Future Prospects of Sodium Metabisulfite in Gold Refining

Looking ahead, the role of sodium metabisulfite in gold refining is poised to expand further. Research continues to uncover new applications and more efficient uses of SMB, promising even better results in terms of gold recovery and environmental conservation. As technology advances, FRT Machinery remains at the forefront, developing innovative solutions that leverage the full potential of sodium metabisulfite to meet the evolving needs of the gold refining sector.

By embracing the use of sodium metabisulfite, gold refineries can achieve higher efficiency, improved safety standards, and a reduced environmental impact. FRT Machinery’s commitment to innovation ensures that these benefits are realized through advanced machinery and processes designed specifically for the gold refining industry.