gold refining tools

Gold Refining Tools Essential Equipment for Purifying Gold

Gold refining is a critical process in the transformation of raw, impure gold into pure gold, ready for use in various industries. To achieve this, a range of specialized gold refining tools are used, each designed to aid in the different stages of the refining process. Whether for large-scale industrial operations or small-scale artisanal gold refiners, having the right tools is essential for achieving high-purity gold.

The Importance of Proper Gold Refining Tools

Refining gold involves removing impurities such as silver, copper, and other metals that may be present in the raw material. The process typically includes melting, chemical reactions, and separation techniques. Using the correct gold refining tools not only ensures that these processes run efficiently but also helps achieve the desired purity of the final product. Each tool serves a specific purpose and is designed to handle the demands of refining gold in both small and large quantities.

Crucibles: A Key Tool for Melting Gold

One of the most important gold refining tools is the crucible. Crucibles are heat-resistant containers used for melting gold and other metals. Made from materials like graphite, clay, or ceramic, crucibles can withstand the extreme temperatures required to melt gold, which typically has a melting point of 1,064°C (1,947°F).

A high-quality crucible is essential to ensure that the molten gold does not react with the container material, which could contaminate the gold. Crucibles come in various sizes depending on the amount of gold being refined, making them suitable for both hobbyists and industrial refiners.

Tongs and Safety Gear

Handling molten gold requires specialized gold refining tools such as tongs. Tongs are designed to safely grip and move the crucible when it is filled with molten metal. Made from materials that can resist heat, tongs allow refiners to transfer the crucible without risking burns or spills.

In addition to tongs, safety gear like heat-resistant gloves, aprons, and face shields are also important gold refining tools. They protect the refiner from the high temperatures and potentially harmful fumes that may be released during the refining process. Safety is paramount when working with molten gold, and using the right tools minimizes the risk of accidents.

Furnaces for Melting and Smelting

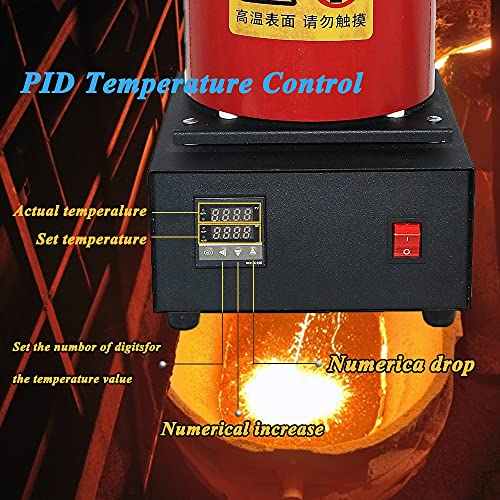

A furnace is another essential tool in the gold refining process. Furnaces generate the high temperatures necessary to melt gold and carry out smelting processes. There are different types of furnaces available, including electric, propane, and induction furnaces. The choice of furnace depends on the scale of the refining operation and the amount of gold being processed.

For large-scale operations, industrial furnaces can handle significant quantities of gold, while small, portable furnaces are ideal for hobbyists or small refiners. The furnace’s temperature controls and insulation are critical in ensuring efficient gold melting without losing material to oxidation or other reactions.

Chemical Solutions and Reactants

In chemical gold refining, various chemicals are required to dissolve the gold and separate it from other metals. One of the most common chemicals used is aqua regia, a mixture of nitric acid and hydrochloric acid. Aqua regia dissolves gold, allowing it to be separated from impurities. Other important chemicals include sodium metabisulfite, which is used to precipitate gold out of the solution, and borax, which is used as a flux to remove impurities during melting.

Using proper glassware and chemical containers is important when working with these solutions. Lab-grade beakers, flasks, and funnels are necessary gold refining tools in the chemical process, ensuring safety and precision.

Filters and Refining Media

Filtration plays a crucial role in purifying gold after it has been dissolved in a chemical solution. Filter papers, funnels, and vacuum filtration systems are commonly used to separate impurities from the gold solution. These gold refining tools help ensure that only the purest gold remains after the filtration process.

Refining media, such as activated carbon and resins, are also used in some gold refining processes. These materials can absorb impurities or gold particles, depending on the specific refining method being used.

Electrolytic Cells for Advanced Refining

Electrolytic cells are advanced gold refining tools used in high-purity refining processes. In this method, gold is dissolved in a solution, and an electric current is passed through it. The gold is then deposited onto a cathode while impurities remain in the solution. This technique is highly efficient and produces gold of 99.99% purity or higher.

Electrolytic refining requires specialized equipment, including anodes, cathodes, and a power supply. While this method is typically used in large-scale industrial operations, it is also possible to set up smaller-scale electrolytic systems for hobbyists or small refiners seeking high-purity gold.

Molds for Casting Gold

After refining, gold is typically cast into bars, coins, or other forms. Molds are critical gold refining tools used to shape the molten gold as it cools. Made from heat-resistant materials like graphite or steel, molds come in various sizes and shapes, depending on the desired final product.

Proper mold selection is important, as it affects the appearance and quality of the finished gold product. Some refiners also use stamping or engraving tools to mark their refined gold with identification or branding.

Digital Scales and Assaying Tools

Accurate measurement is key in the gold refining process, and digital scales are essential gold refining tools for weighing gold before and after refining. High-precision scales ensure that refiners can track the yield and purity of their refined gold.

Assaying tools are also used to verify the purity of refined gold. These tools can include touchstone kits, X-ray fluorescence (XRF) analyzers, or spectrometers, which determine the exact composition of the gold.

Gold refining is a complex process that requires a variety of specialized gold refining tools to achieve high levels of purity. From crucibles and furnaces for melting, to chemical solutions for purification, and molds for casting, each tool plays a critical role in transforming raw gold into a valuable, refined product. Whether refining gold on a large industrial scale or in a small workshop, having the right tools is essential for success in the gold refining process.