Gold Smelting Furnace For Microwaves

Gold Smelting Furnace for Microwaves: Revolutionizing Precious Metal Extraction

Gold smelting has been a cornerstone of human civilization for millennia, evolving from rudimentary methods to sophisticated techniques that leverage modern technology. One such innovation is the gold smelting furnace designed specifically for microwave applications. Developed by FRT Machinery, this cutting-edge technology promises to transform how we approach the smelting process, making it more efficient and environmentally friendly.

Understanding the Basics of Microwave Gold Smelting Furnaces

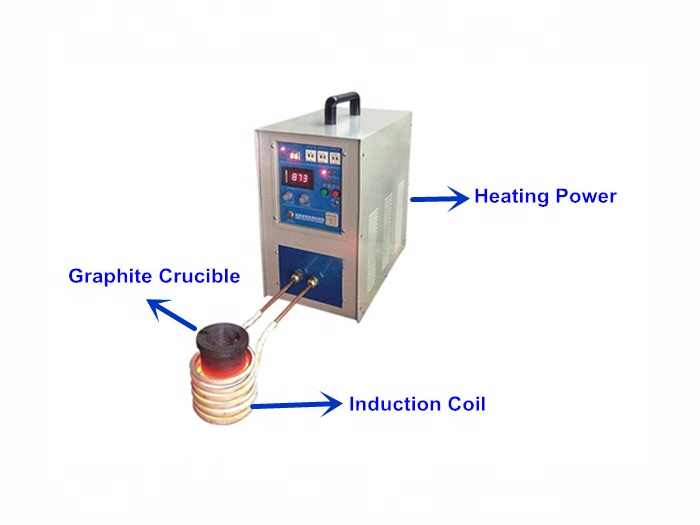

A microwave gold smelting furnace operates on the principle of using electromagnetic waves to heat materials internally, bypassing traditional conduction and convection methods. This unique approach ensures that energy is directly applied to the material being processed, leading to faster heating times and reduced energy consumption compared to conventional furnaces.

Advantages of Using a Microwave Gold Smelting Furnace

The adoption of microwave technology in smelting furnaces offers several advantages over traditional methods. Firstly, it significantly reduces the time required for the smelting process, which translates into higher productivity rates. Secondly, because microwaves heat materials uniformly from within, there’s less chance of overheating or uneven melting, ensuring better control over the smelting process. Lastly, microwave furnaces are generally more compact and require less maintenance, making them ideal for both small-scale operations and large industrial setups.

Design Considerations for Microwave Gold Smelting Furnaces

When designing a microwave gold smelting furnace, engineers at FRT Machinery focus on optimizing key parameters such as frequency, power output, and chamber design to achieve optimal performance. The frequency chosen must penetrate the material effectively without causing excessive surface heating. Power output needs to be adjustable to accommodate different batch sizes and materials. Additionally, the chamber’s shape and size play crucial roles in distributing the microwaves evenly across the load.

Operational Efficiency of Microwave Gold Smelting Furnaces

One of the most compelling reasons for choosing a microwave gold smelting furnace is its operational efficiency. These furnaces can reach high temperatures quickly, allowing for rapid processing cycles. Moreover, they provide precise temperature control, essential for achieving consistent results in smelting operations. By minimizing energy loss through radiation and convection, microwave furnaces also contribute to lower overall operating costs.

Sustainability Benefits of Microwave Gold Smelting Furnaces

Beyond improving operational efficiency, microwave gold smelting furnaces have significant environmental benefits. They consume less energy per unit of output compared to traditional furnaces, reducing carbon footprints associated with smelting activities. Furthermore, their design often incorporates features that minimize waste and emissions, aligning with global sustainability goals.

Future Prospects of Microwave Gold Smelting Technology

As research into microwave-assisted processes continues, it’s likely that we’ll see even more advanced versions of these furnaces emerge. Innovations might include smarter controls, enhanced safety features, and further reductions in energy requirements. FRT Machinery remains committed to pushing the boundaries of what’s possible with microwave gold smelting technology, ensuring that the industry stays at the forefront of sustainable manufacturing practices.

By embracing microwave gold smelting furnaces, manufacturers can not only streamline their operations but also contribute positively to environmental sustainability efforts. As technology evolves, so too will the capabilities of these innovative devices, setting new standards for efficiency and eco-friendliness in the precious metals industry.