gold smelting supplies

A Guide to Essential Gold Smelting Supplies

Gold smelting is a process that involves melting gold ore or scrap to separate the precious metal from impurities. For anyone involved in this craft, whether at an industrial level or as a hobbyist, having the right gold smelting supplies is crucial. From the equipment used to the materials required, these supplies play an important role in ensuring successful smelting. This article will explore the key supplies needed for gold smelting, their uses, and tips on choosing the best products.

Understanding Gold Smelting Supplies

Gold smelting supplies encompass a wide range of materials and tools used to refine gold through heat. These supplies include everything from furnaces and crucibles to flux and protective gear. Each element has a specific function and is essential for ensuring safety, efficiency, and precision in the smelting process. For those looking to produce pure gold or recover gold from scrap, investing in quality gold smelting supplies is a must.

Furnaces for Gold Smelting

One of the most important pieces of equipment in gold smelting is the furnace. Furnaces are used to heat gold ore or scrap to its melting point, separating it from impurities. There are several types of furnaces available, depending on the scale of your operation:

- Electric Furnaces: Ideal for small-scale smelting or hobbyists, electric furnaces provide controlled heat and are easy to use.

- Propane Furnaces: These are portable and versatile, suitable for medium to large-scale operations. They offer higher temperatures and faster smelting times.

- Induction Furnaces: For industrial operations, induction furnaces are used because of their precision and ability to smelt large quantities of gold at once.

Choosing the right furnace depends on your specific smelting needs, but all types require a reliable heat source to melt the gold effectively.

Crucibles: Essential Smelting Containers

Crucibles are specialized containers designed to hold molten metal during the smelting process. They must withstand extremely high temperatures and resist corrosion from molten materials. The most common crucibles used in gold smelting are made from ceramic, graphite, or clay.

- Ceramic Crucibles: Durable and heat-resistant, ceramic crucibles are ideal for smelting gold at higher temperatures.

- Graphite Crucibles: Known for their excellent thermal conductivity, graphite crucibles are commonly used in gold smelting due to their durability and ability to retain heat.

Crucibles come in different sizes to accommodate various quantities of gold, so it’s important to choose one that matches your smelting setup.

Flux for Purifying Gold

Flux is another crucial component in the list of gold smelting supplies. It is a chemical agent added to the molten material to help remove impurities. The most commonly used flux materials include borax and soda ash, both of which facilitate the separation of metals and impurities.

- Borax: Borax is widely used in smelting to lower the melting point of the ore, making the smelting process easier and more efficient.

- Soda Ash: Similar to borax, soda ash helps in refining the gold and ensures that unwanted materials are removed from the molten metal.

Adding the right amount of flux is key to producing purer gold, as it prevents oxidation and helps gather impurities into a manageable form known as slag.

Safety Gear for Gold Smelting

Gold smelting involves high temperatures and handling of molten materials, which makes safety gear an essential part of your gold smelting supplies. Personal protective equipment (PPE) includes heat-resistant gloves, face shields, and fireproof aprons, all designed to protect the smelter from burns and other injuries.

- Heat-Resistant Gloves: These gloves protect your hands from extreme temperatures when handling crucibles and furnaces.

- Face Shields: Full face shields provide protection from molten metal splashes, heat, and harmful gases.

- Fireproof Aprons: Made from materials like leather or specialized fabrics, fireproof aprons protect your body from heat and accidental spills.

Investing in proper safety gear is not only recommended but necessary for ensuring a safe smelting environment.

Molds and Tools for Gold Smelting

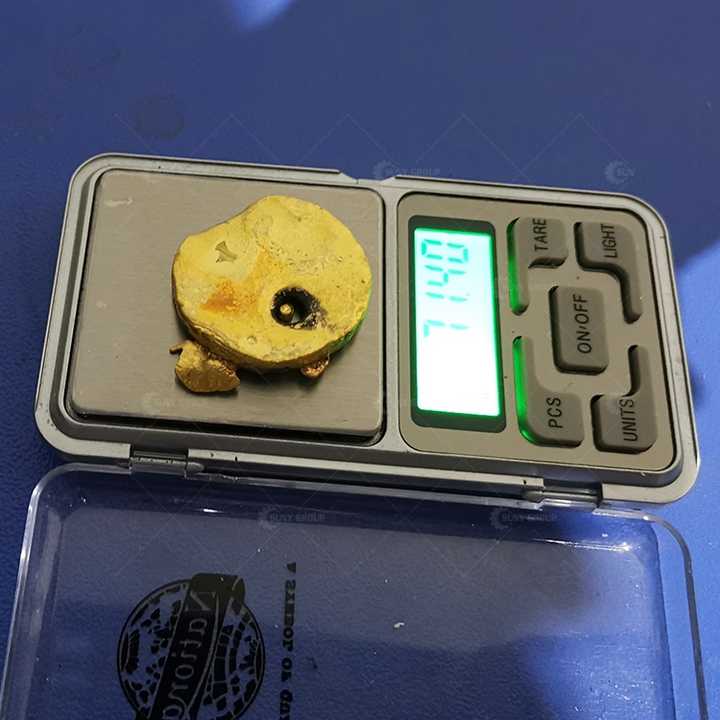

Once the gold has been successfully smelted, it needs to be poured into molds to solidify into a usable form. Molds are made from heat-resistant materials such as graphite or cast iron. These molds shape the molten gold into bars, ingots, or smaller forms, depending on your requirements.

In addition to molds, basic smelting tools like tongs, ladles, and thermometers are essential for handling the molten metal and monitoring the temperature throughout the process.

- Tongs: Designed for lifting and handling crucibles safely, tongs are crucial for moving molten gold.

- Ladles: Ladles are used to pour the molten gold into molds without spilling.

- Thermometers: Temperature control is vital during smelting, and a high-temperature thermometer helps ensure the gold is melted at the correct temperature.

Having the right gold smelting supplies is essential for anyone involved in the gold refining process. From furnaces and crucibles to flux and safety gear, each element plays a critical role in ensuring the success of the smelting operation. Whether you are a hobbyist or a professional refiner, investing in high-quality supplies will improve the efficiency and safety of your smelting process.