Gold Smelting Techniques

Gold Smelting Techniques: Unlocking the Value with Precision and Care

FRT Machinery: Enhancing Gold Smelting Efficiency

Gold smelting is a time-honored technique that involves heating gold ore to a high temperature so that the gold can be separated from other minerals and impurities. This process requires specialized equipment and expertise to ensure optimal results. At FRT Machinery, we specialize in providing state-of-the-art solutions for gold smelting, ensuring that our clients achieve the highest purity levels efficiently.

Understanding the Fundamentals of Gold Smelting

Before diving into the specifics of advanced techniques, it’s essential to understand the basics of gold smelting. The process typically begins with crushing the gold ore into smaller pieces. These pieces are then mixed with flux—a substance that helps to remove impurities—and placed in a crucible. The crucible is heated using a furnace until the gold melts and separates from other materials. Our machinery at FRT Machinery is designed to handle these initial steps seamlessly, setting the stage for more sophisticated processing.

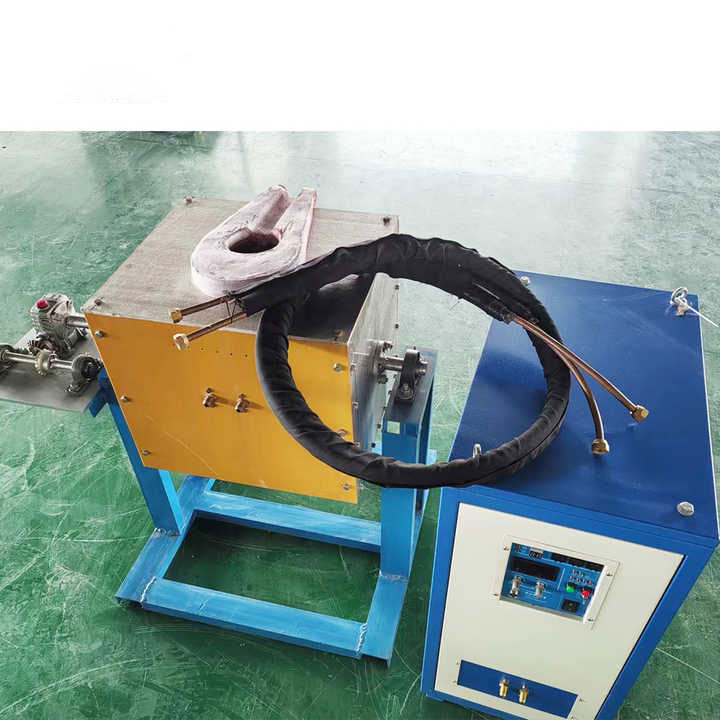

FRT Machinery’s Innovative Furnace Designs for Gold Smelting

One of the critical components in gold smelting is the furnace. FRT Machinery offers a range of furnaces tailored specifically for this application. These furnaces feature advanced insulation materials and energy-efficient designs that help in achieving higher temperatures while reducing fuel consumption. Moreover, our furnaces are equipped with precise temperature control systems, allowing operators to maintain the exact conditions necessary for efficient smelting.

Advanced Flue Gas Treatment Systems by FRT Machinery

During the smelting process, harmful gases are produced, which need to be treated before they are released into the environment. FRT Machinery has developed innovative flue gas treatment systems that capture and neutralize these gases effectively. By integrating these systems with our smelting furnaces, we ensure that our clients comply with environmental regulations while also recovering valuable metals from the waste gases, thereby enhancing overall efficiency and sustainability.

FRT Machinery’s Automated Sampling Techniques for Quality Assurance

Quality assurance is crucial in gold smelting to ensure that the final product meets the required standards. FRT Machinery has developed automated sampling techniques that allow for continuous monitoring of the smelting process. These systems collect samples at regular intervals and analyze them to ensure that the gold content and purity remain consistent throughout the batch. This real-time data enables operators to make adjustments on the fly, guaranteeing superior quality output every time.

Conclusion: Elevating Gold Smelting with FRT Machinery

In conclusion, the art of gold smelting has evolved significantly over the years, thanks to advancements in technology and innovative approaches. FRT Machinery is committed to pushing the boundaries of what’s possible in this field, offering a comprehensive suite of solutions—from high-efficiency furnaces to advanced flue gas treatment systems—that not only streamline the smelting process but also enhance its environmental sustainability. Whether you’re a small-scale operator or part of a large mining corporation, partnering with FRT Machinery means gaining access to cutting-edge tools and techniques that will elevate your gold smelting operations to new heights.