Homemade Gold Smelting

Introduction to Homemade Gold Smelting

Gold smelting is an ancient technique used to extract pure gold from its ore. With the right tools and knowledge, it’s possible to perform this process at home, albeit on a smaller scale. Whether you’re a hobbyist looking to refine your skills or someone interested in understanding the basics, this guide will walk you through the essentials of homemade gold smelting.

Preparing for Homemade Gold Smelting

Before you begin, ensure that you have all the necessary safety gear and equipment. This includes gloves, goggles, a face mask, and a well-ventilated area. For the smelting process itself, you’ll need a crucible, a heat source such as a propane torch or a specialized furnace, and flux materials like borax. FRT Machinery offers compact furnaces designed specifically for small-scale operations, making them ideal for beginners and hobbyists alike.

Selecting the Right Equipment for Homemade Gold Smelting

Choosing the correct equipment is crucial for successful smelting. A crucible must be able to withstand extremely high temperatures without degrading. FRT Machinery’s crucibles are made from high-quality materials designed to resist thermal shock and maintain integrity during the smelting process. Additionally, investing in a quality furnace or torch can make a significant difference in achieving the required temperatures (upwards of 1,000°C) necessary for melting gold.

The Process of Homemade Gold Smelting

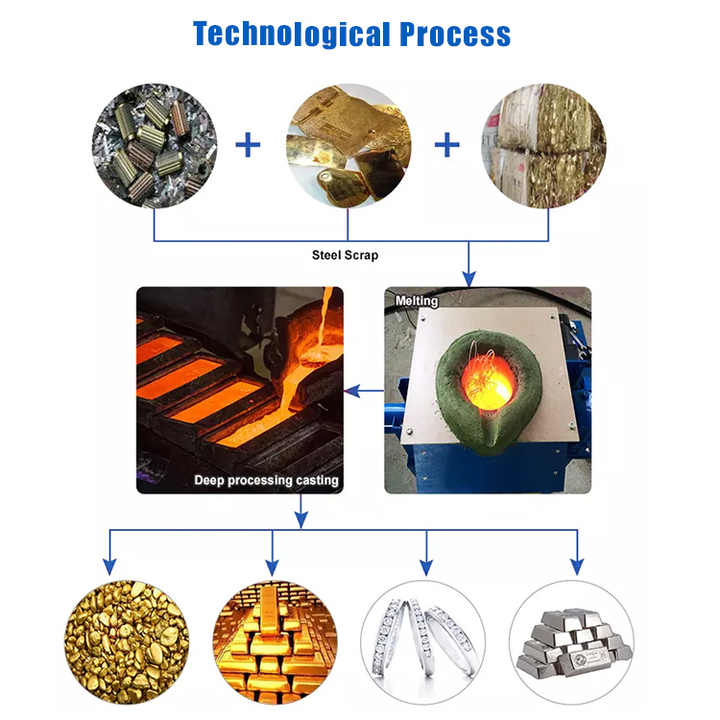

The actual process of smelting involves heating gold ore to its melting point, allowing impurities to separate from the gold. This separation is facilitated by adding fluxes which help form slag—a waste product that floats on top of the molten gold. Once cooled, the slag can be easily removed, leaving behind purified gold.

Steps Involved in Homemade Gold Smelting

1.Crushing and Grinding: Start by reducing the size of your gold ore into fine particles.

2.Roasting: Heat the crushed ore to oxidize sulfides present in the ore.

3.Smelting: Place the roasted material in a crucible along with flux agents. Heat until the gold melts.

4.Pouring: Carefully pour the molten gold into molds.

5.Cooling and Extraction: Allow the gold to cool completely before removing it from the mold.

Safety Considerations in Homemade Gold Smelting

Safety should always be your top priority when dealing with high-temperature processes. Always wear protective clothing and work in a well-ventilated space to avoid inhalation of toxic fumes. Keep a fire extinguisher nearby and never leave the smelting process unattended.

Important Safety Tips for Homemade Gold Smelting

– Use proper ventilation or work outdoors.

– Avoid wearing loose clothing that could catch fire.

– Have a bucket of sand or a fire blanket ready in case of emergencies.

– Regularly inspect your equipment for wear and tear.

Conclusion: Advancing Your Skills in Homemade Gold Smelting

As you gain more experience, you might consider experimenting with different types of ores or refining techniques. Remember, practice makes perfect. By continuously improving your setup and methods, you can achieve higher purity levels in your gold smelting projects. FRT Machinery supports enthusiasts and professionals with reliable tools and resources, ensuring every step of your smelting journey is safe and efficient.

By following these guidelines, you’re setting yourself up for success in homemade gold smelting. Whether you’re refining gold for jewelry making or simply exploring metallurgy as a hobby, the satisfaction derived from seeing raw materials transform into gleaming bars of gold is unparalleled.