how to purife gold

How to Purify Gold Methods and Techniques for Achieving High Purity

Gold purification is a critical process in the precious metals industry, essential for transforming raw gold into a high-purity product suitable for various applications. Whether you’re a jeweler, a refiner, or an enthusiast interested in gold recovery, understanding how to purify gold effectively can enhance the quality and value of your gold. This article explores various methods and techniques used in gold purification, providing a comprehensive guide to achieving gold of the highest purity.

Understanding Gold Purification

Gold purification involves removing impurities from raw gold to produce a refined, high-quality product. Impurities in raw gold can include other metals, minerals, and non-metallic elements. The purification process aims to separate these impurities, resulting in gold with a purity level often reaching 99.99%. The methods used for gold purification vary depending on the scale of operation, the form of gold, and the specific impurities present.

Methods for Gold Purification

1. Electrolytic Refining

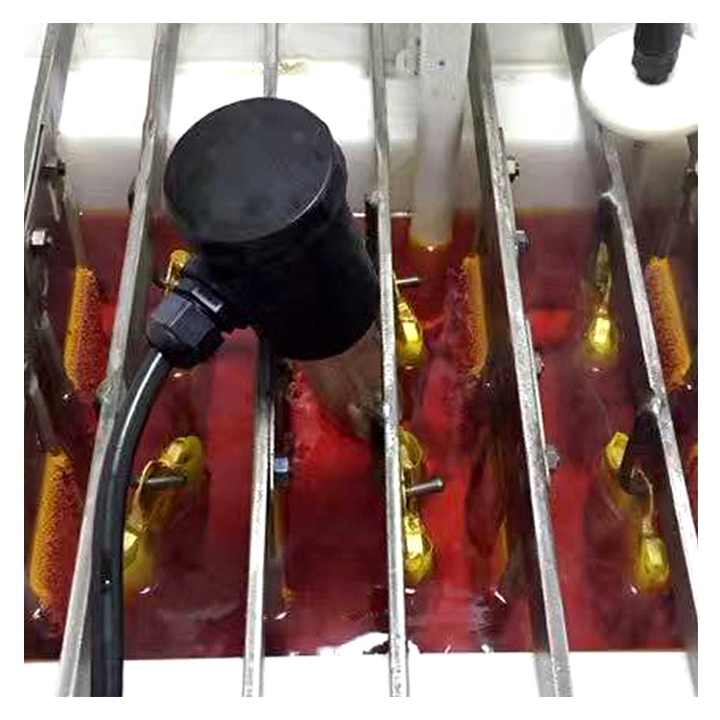

Electrolytic refining is one of the most commonly used methods for purifying gold. This process involves dissolving gold in a solution and using electrolysis to separate impurities from the gold. Here’s how it works:

- Preparation: Raw gold is dissolved in a suitable electrolyte solution, often containing gold chloride or gold cyanide.

- Electrolysis: An electric current is passed through the solution, causing the gold to migrate to a cathode, where it is deposited as pure gold. Impurities are left behind in the solution.

- Final Purification: The deposited gold is collected, cleaned, and melted into bars or other forms.

Electrolytic refining is highly effective and is used to produce gold with a purity level of up to 99.99%. It is widely used in industrial-scale operations and refineries.

2. Chemical Refining

Chemical refining involves the use of chemicals to dissolve and separate impurities from gold. One common method is the use of aqua regia, a mixture of hydrochloric and nitric acids. The process includes:

- Dissolution: Raw gold is dissolved in aqua regia, which reacts with the gold to form a soluble gold chloride complex.

- Separation: Impurities are separated as insoluble residues or form soluble chlorides.

- Precipitation: Pure gold is precipitated from the solution using reducing agents such as sodium metabisulfite or oxalic acid.

- Collection: The precipitated gold is filtered, washed, and melted.

Chemical refining is effective for high-purity gold and is often used for smaller-scale operations or specific gold-containing materials.

3. Miller Process

The Miller process is a method used to refine gold by blowing chlorine gas through molten gold. This process is effective for removing impurities such as base metals. Here’s how it works:

- Chlorination: Chlorine gas is introduced into molten gold, which reacts with impurities to form chlorides.

- Separation: The chlorides float to the surface, where they can be skimmed off.

- Purification: The remaining gold is highly pure, typically reaching up to 99.5%.

The Miller process is relatively simple and fast but is less effective for achieving the highest levels of purity compared to other methods.

4. Cupellation

Cupellation is an ancient method used to refine gold, particularly from ores. It involves heating gold with lead and flux in a furnace. The process includes:

- Heating: Gold ore is mixed with lead and flux and heated in a cupel (a porous container) in a furnace.

- Oxidation: Lead and impurities are oxidized and absorbed by the cupel, leaving behind pure gold.

- Recovery: The pure gold is collected from the cupel and melted into bars.

Cupellation is less commonly used today but is still employed in some traditional refining operations.

5. Gravity Separation

Gravity separation is a physical method used to purify gold, particularly in gold mining. This method relies on the differences in density between gold and other materials. The process includes:

- Concentration: Gold-containing materials are processed through gravity-based equipment such as sluice boxes or shaking tables.

- Separation: Gold is separated from other materials based on its higher density.

- Refinement: The separated gold is further purified using additional methods as needed.

Gravity separation is effective for extracting gold from ores and concentrates but often requires further purification to achieve high purity.

Choosing the Right Method

The choice of gold purification method depends on several factors, including:

- Purity Requirements: Different methods achieve varying levels of purity. Electrolytic refining and chemical refining are best for the highest purity levels.

- Scale of Operation: Small-scale operations may use chemical refining or gravity separation, while large refineries often use electrolytic or Miller processes.

- Form of Gold: The method used may vary depending on whether the gold is in ore, concentrate, or scrap form.

Gold purification is a vital process in the precious metals industry, ensuring that raw gold is transformed into a high-quality product. Methods such as electrolytic refining, chemical refining, Miller process, cupellation, and gravity separation offer different approaches to achieving gold of various purity levels. By understanding these methods and selecting the appropriate one for your needs, you can effectively purify gold and enhance its value and quality. Whether you’re working in a large-scale refinery or engaged in small-scale refining, mastering gold purification techniques is key to achieving excellent results and maintaining the highest standards of purity.