instant gold refining

Instant Gold Refining A Quick Overview

In the world of precious metals, instant gold refining has emerged as a popular solution for those looking to quickly and efficiently purify gold. This process appeals to jewelers, miners, and even hobbyists who want to ensure they obtain the highest possible value from their gold. This article explores the concept of instant gold refining, its methods, benefits, and considerations for anyone interested in the process.

Understanding Instant Gold Refining

Instant gold refining refers to the rapid purification of gold from impure sources, such as scrap gold, jewelry, or gold dust. This method is particularly appealing due to its efficiency and the ability to achieve high purity levels in a short amount of time. Instant refining can be performed using various techniques, but the most common methods include chemical processes and electrolytic refining.

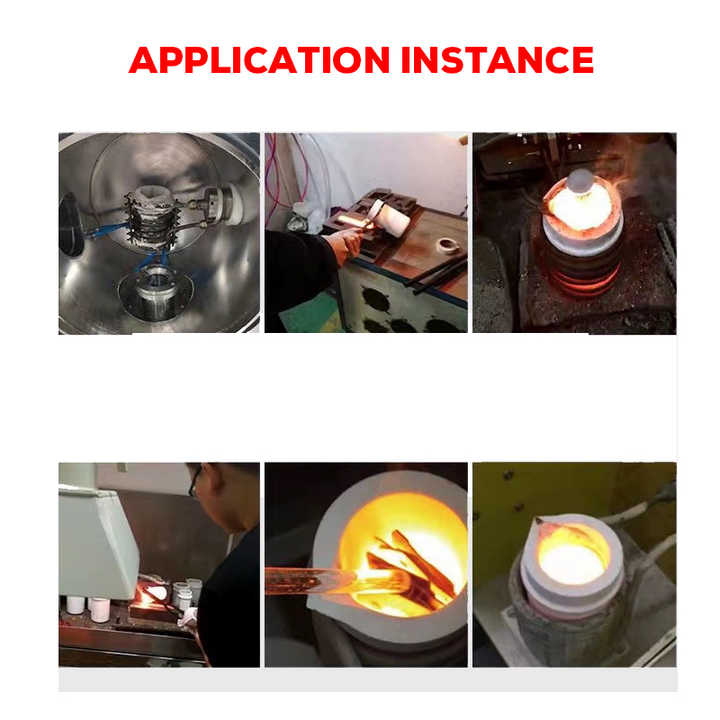

Common Methods of Instant Gold Refining

Chemical Refining

One of the most straightforward methods for instant gold refining involves chemical processes. Typically, this method uses a combination of acids to dissolve impurities. Aqua regia, a mixture of hydrochloric and nitric acids, is often employed to dissolve gold and separate it from other metals.

- Dissolving the Gold: The impure gold is placed in the aqua regia solution, where it dissolves, leaving behind other metals as solids.

- Precipitating Gold: Once dissolved, a reducing agent, such as sodium metabisulfite or methyl ethyl ketone, is introduced to precipitate pure gold from the solution. This process can be completed in a matter of hours, allowing for instant results.

- Filtering and Drying: The precipitated gold is then filtered out, washed, and dried to yield high-purity gold powder or granules.

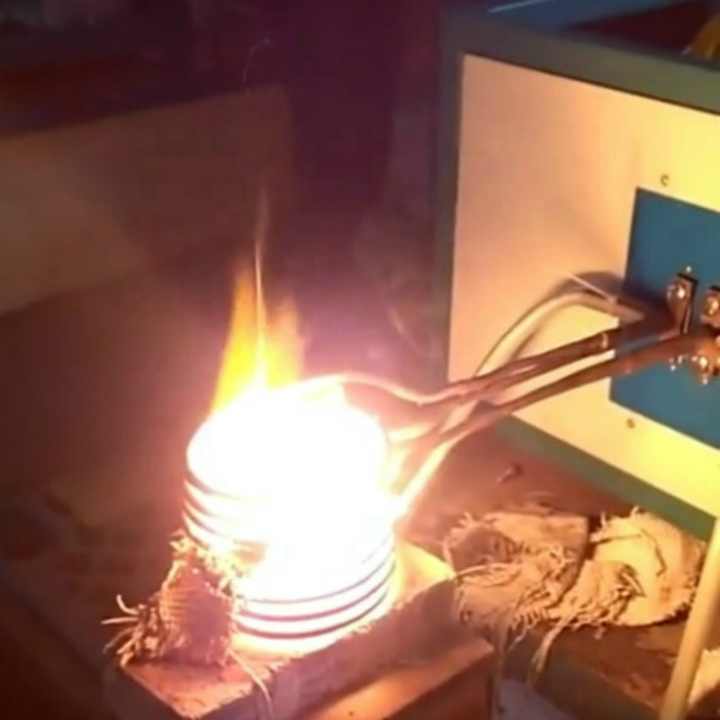

Electrolytic Refining

Electrolytic refining is another method that allows for instant gold refining. This technique utilizes an electric current to separate gold from other metals in a solution.

- Setting Up the Cell: The impure gold is placed in an electrolytic cell filled with a gold chloride solution. An electric current is then passed through the cell.

- Deposition of Gold: During this process, pure gold deposits onto cathodes while impurities remain in the solution, effectively refining the gold.

- Efficiency: Electrolytic refining is known for its ability to achieve purity levels of 99.9% or higher, making it a favored method for jewelers and refiners looking for instant results.

Benefits of Instant Gold Refining

- Speed: The most significant advantage of instant gold refining is the speed at which it can be accomplished. Both chemical and electrolytic methods can produce refined gold in a matter of hours.

- High Purity: Instant refining techniques can yield gold with purity levels exceeding 99.9%, which is essential for both commercial and investment purposes.

- Convenience: For jewelers and small-scale refiners, having access to instant refining methods allows them to quickly process scrap and reclaim valuable materials without lengthy delays.

Considerations for Instant Gold Refining

While instant gold refining offers numerous benefits, there are important considerations to keep in mind:

- Safety: The use of strong acids and chemicals requires appropriate safety measures. Personal protective equipment (PPE) such as gloves, goggles, and masks should always be worn.

- Environmental Concerns: Proper disposal of chemical waste is crucial to minimize environmental impact. Refiners must adhere to local regulations regarding hazardous materials.

- Cost: While instant gold refining can save time, the cost of chemicals and equipment can add up. It’s important for individuals and businesses to weigh these costs against the potential gains from refining.

Instant gold refining is a valuable process for those looking to quickly purify gold from various sources. By utilizing chemical and electrolytic methods, refiners can achieve high purity levels in a fraction of the time required by traditional methods. However, it is essential to prioritize safety and environmental considerations when engaging in these practices. As technology continues to evolve, instant gold refining will likely become even more accessible, making it an attractive option for jewelers and miners alike.