Miller Process For Gold Refining

Understanding the Miller Process for Gold Refining

Gold refining is an essential step in extracting pure gold from its raw form. One of the oldest and most effective methods for achieving this is theMiller Process. Developed by Francis Miller in the mid-19th century, this method has stood the test of time due to its efficiency and effectiveness. FRT Machinery, a leading manufacturer in the field of gold refining equipment, offers state-of-the-art solutions that incorporate the principles of the Miller process.

The Miller Process: An Overview

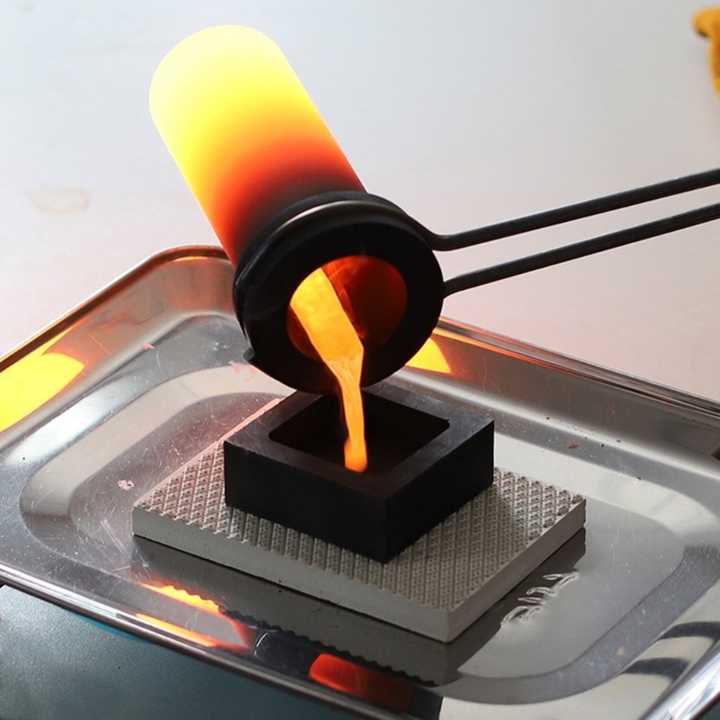

TheMiller processinvolves treating the raw gold with chlorine gas to refine it. This process is particularly useful when dealing with gold that contains platinum group metals (PGMs), which cannot be removed using other common refining techniques such as the cyanidation process. By understanding the basics of how the Miller process works, one can appreciate the importance of this technique in modern gold refining practices.

Equipment Needed for the Miller Process

To carry out theMiller process, specialized equipment is required. FRT Machinery provides a range of equipment designed specifically for this purpose. This includes chlorine generators, which are crucial for producing the chlorine gas used in the process. Additionally, safety systems are integrated into these machines to ensure the safe handling of chlorine gas, which is corrosive and toxic.

Safety Measures in the Miller Process

Safety is paramount when working with chlorine gas during theMiller process. FRT Machinery’s equipment is engineered with advanced safety features to minimize risks. These include automatic shut-off valves and containment systems that prevent leaks. Training employees on the proper handling of the equipment and wearing appropriate protective gear is also emphasized to maintain a safe working environment.

Advantages of Using the Miller Process

TheMiller processoffers several advantages over other gold refining methods. It is particularly effective in purifying gold that contains PGMs, ensuring a higher purity level. Moreover, the process is relatively quick, reducing the overall time required for refining. This efficiency translates into cost savings for refineries, making the Miller process a preferred choice among professionals in the industry.

Challenges and Limitations

Despite its benefits, theMiller processalso comes with challenges. The primary concern is the handling of chlorine gas, which requires stringent safety protocols. Additionally, the process is not suitable for all types of gold ores; it works best with certain specific compositions. FRT Machinery addresses these limitations by offering comprehensive support, including training and maintenance services, to ensure optimal operation of their equipment.

Future Innovations in the Miller Process

As technology advances, so does theMiller process. FRT Machinery invests heavily in research and development to improve existing processes and develop new technologies. Innovations aim to enhance safety, increase efficiency, and reduce environmental impact. By staying at the forefront of technological advancements, FRT Machinery ensures that the Miller process remains a viable and effective method for gold refining well into the future.

In conclusion, theMiller processcontinues to play a vital role in the gold refining industry. Its effectiveness, especially in refining gold containing PGMs, makes it indispensable. With the right equipment and safety measures in place, refineries can benefit greatly from this time-tested method. FRT Machinery’s commitment to innovation and quality ensures that the Miller process remains a reliable solution for gold refiners worldwide.