Miller Process Refining Gold Wikihow

Understanding the Miller Process for Refining Gold: A Comprehensive Guide

Gold, one of the most precious metals on Earth, has been sought after for centuries due to its lustrous appearance and high value. However, raw gold often contains impurities that diminish its quality and marketability. This is where the Miller Process comes into play. Developed by Francis Miller in the late 19th century, this method has become a staple in the gold refining industry. In this guide, FRT Machinery will walk you through the intricacies of the Miller process, explaining how it works and why it’s essential for achieving pure gold.

The Basics of the Miller Process for Refining Gold

The Miller process involves the use of chlorine gas to refine gold. This technique is particularly effective for purifying gold that contains silver as an impurity. When chlorine gas is passed over the molten gold-silver alloy, it reacts with the silver (and other base metals) but not with gold. The result is a layer of silver chloride on the surface of the molten metal, which can be removed, leaving behind nearly pure gold.

Key Steps in the Miller Process for Refining Gold

To understand the Miller process better, let’s break down its key steps:

1.Preparation: The gold ore is first crushed and refined to remove large impurities. It is then melted and mixed with silver to form an alloy.

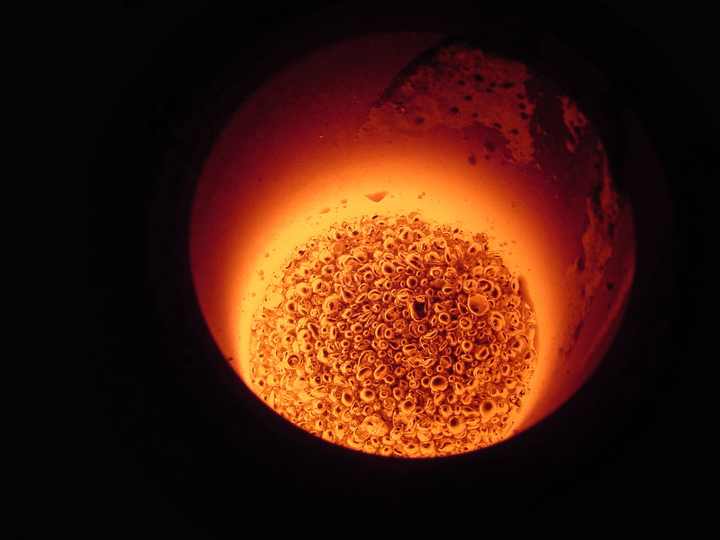

2.Chlorination: Chlorine gas is introduced into the molten alloy under controlled conditions. The temperature must be precisely maintained to ensure optimal reaction rates without damaging the gold.

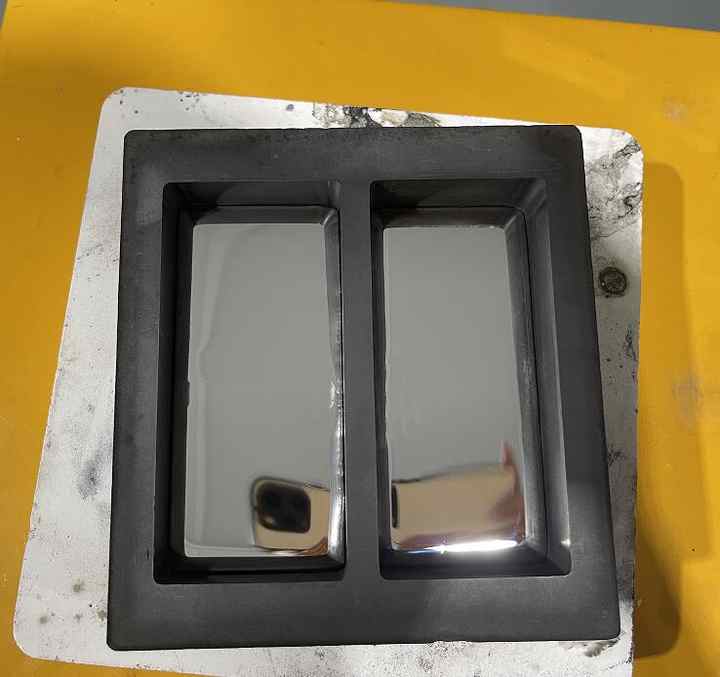

3.Separation: As the reaction progresses, silver chloride forms on the surface of the molten mixture. This layer is carefully scraped off, separating it from the gold.

4.Final Purification: After several rounds of chlorination and separation, the remaining gold is nearly free of impurities, typically reaching a purity level of 99.95%.

Advantages of Using the Miller Process for Refining Gold

The Miller process offers several advantages over other refining methods:

-Efficiency: It is highly efficient at removing silver and other base metals from gold.

-Speed: Compared to other processes like the Wohlwill process, the Miller method is faster and requires less energy.

-Cost-Effectiveness: Due to its efficiency and speed, the Miller process is cost-effective for industrial-scale operations.

Applications of the Miller Process for Refining Gold

The Miller process is widely used in various industries where high-purity gold is required. Some common applications include:

-Jewelry Manufacturing: In the jewelry industry, pure gold is essential for creating high-quality pieces.

-Electronics Industry: Electronic components often require gold plating, necessitating the use of refined gold.

-Investment Grade Gold: Investors prefer gold bars and coins made from refined gold due to their higher value and purity guarantees.

Challenges and Limitations of the Miller Process for Refining Gold

Despite its many benefits, the Miller process also faces some challenges:

-Environmental Concerns: The use of chlorine gas can pose environmental risks if not handled properly.

-Limited Scope: While excellent for removing silver and other base metals, the Miller process is not suitable for gold containing certain other impurities such as platinum group metals.

-Safety Precautions: Special care must be taken during the chlorination step to ensure worker safety and prevent accidental leaks.

Future Innovations in the Miller Process for Refining Gold

As technology advances, so does the refining industry. Researchers are continually looking for ways to improve the Miller process, making it safer, more efficient, and environmentally friendly. Innovations might include:

-Enhanced Containment Systems: To reduce the risk of chlorine gas exposure.

-Alternative Chemicals: Exploring other reagents that could replace chlorine while maintaining effectiveness.

-Automation: Increasing the level of automation in the process to enhance precision and reduce human error.

By understanding the principles behind the Miller process and its ongoing development, we gain insight into the ever-evolving world of gold refining. FRT Machinery remains committed to providing state-of-the-art solutions for refining and processing precious metals, ensuring that the gold industry continues to thrive with sustainable practices.