Mining Extraction And Refining Of Gold

Mining Extraction And Refining Of Gold

Gold, a precious metal cherished for its luster and malleability, has captivated human imagination since ancient times. From the earliest civilizations to modern economies, gold remains a symbol of wealth and stability. This article delves into the intricate processes involved in mining, extracting, and refining gold, highlighting the innovative technologies employed by FRT Machinery to enhance efficiency and sustainability.

Gold Mining Techniques

Gold mining encompasses several methods designed to extract this valuable resource from the earth. Open-pit mining, one of the most common techniques, involves removing layers of soil and rock to access gold deposits near the surface. Underground mining, on the other hand, is used when the ore body is too deep or too far to be reached by open-pit methods. FRT Machinery offers state-of-the-art mining equipment tailored for both scenarios, ensuring optimal extraction rates while minimizing environmental impact.

Extraction Processes of Gold

Once mined, the process of separating gold from its ore begins. Crushing and grinding are initial steps where large chunks of ore are reduced to smaller particles. Following this, leaching solutions like cyanide or mercury are used to dissolve the gold, making it easier to separate from waste materials. FRT Machinery’s advanced extraction systems facilitate these processes efficiently, reducing operational costs and improving recovery rates.

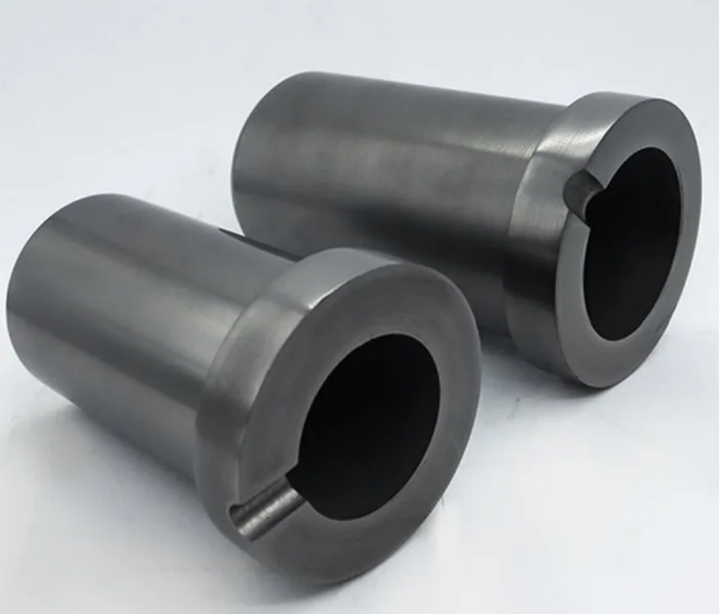

Refining Methods for Gold

After extraction, gold undergoes refining to purify it to the desired level of purity. Common refining techniques include smelting, where gold is melted and impurities are removed; electrolysis, which uses electric currents to refine gold; and chemical leaching, where acids or bases are used to further purify the metal. FRT Machinery provides specialized refining equipment that ensures high-quality output while adhering to stringent environmental standards.

Sustainability in Gold Mining

The gold mining industry faces increasing pressure to adopt sustainable practices. FRT Machinery leads the way with eco-friendly technologies that reduce water consumption, minimize waste production, and lower carbon footprints. By integrating these solutions, mining operations can significantly contribute to environmental conservation efforts without compromising productivity.

Future Innovations in Gold Extraction and Refining

As technology evolves, so does the potential for more efficient and environmentally friendly methods of gold extraction and refining. FRT Machinery invests heavily in research and development to bring cutting-edge innovations to market. These advancements aim at enhancing recovery rates, improving safety standards, and reducing the overall environmental impact of gold mining activities.

By continuously pushing the boundaries of what’s possible, FRT Machinery supports the global shift towards sustainable mining practices, ensuring that future generations can continue to benefit from the world’s natural resources responsibly.