nitric acid for gold refining

Gold refining is a vital process for purifying gold to achieve its highest quality. One of the prominent methods involves using nitric acid for gold refining. This technique is valued for its precision and efficiency in separating gold from other metals. This article explores the role of nitric acid for gold refining, detailing its processes, advantages, and considerations.

Introduction to Nitric Acid for Gold Refining

Nitric acid is a key chemical used in gold refining to purify gold and remove impurities. This acid, known for its strong oxidizing properties, reacts selectively with certain metals, making it ideal for separating gold from alloys or ores. The use of nitric acid for gold refining is a well-established method in the industry, providing reliable results in achieving high-purity gold.

The Process of Using Nitric Acid for Gold Refining

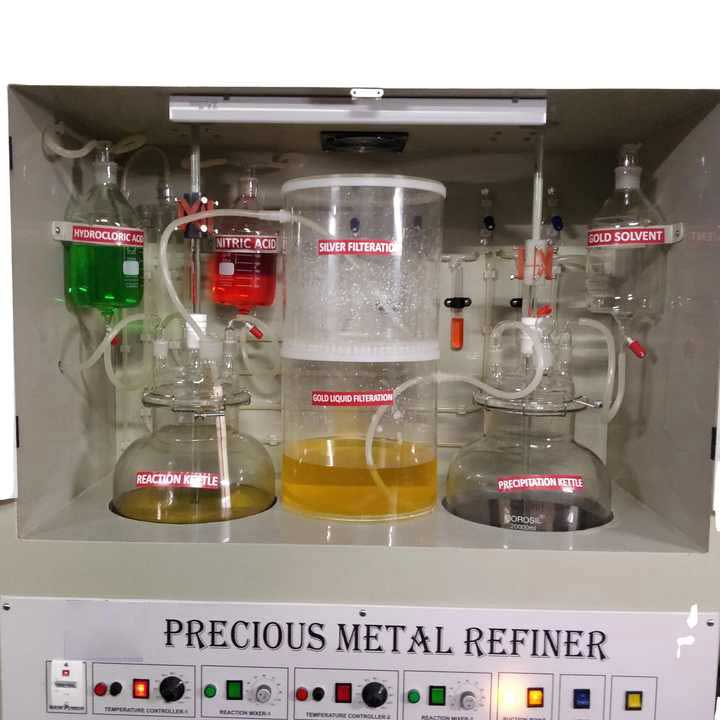

The process of using nitric acid for gold refining typically involves several steps. Initially, gold-bearing material is dissolved in aqua regia, a mixture of nitric acid and hydrochloric acid. This solution dissolves gold, forming chloroauric acid. After this, nitric acid is introduced to the solution to selectively react with other metals such as silver, which form insoluble compounds. These compounds precipitate out, leaving behind a purified gold solution.

One critical aspect of using nitric acid for gold refining is controlling the concentration and reaction conditions. The effectiveness of the process depends on the precise management of these factors, including the temperature and concentration of nitric acid, to ensure that impurities are adequately removed without losing gold.

Advantages of Nitric Acid for Gold Refining

Using nitric acid for gold refining offers several notable advantages. One of the primary benefits is its ability to effectively separate gold from base metals like silver. Nitric acid selectively dissolves these metals, which simplifies the process of obtaining high-purity gold from complex mixtures.

Additionally, nitric acid for gold refining is a well-established method with a proven track record. The process has been refined over many years, making it a reliable choice for gold refiners. Its efficiency in achieving high-purity gold makes it a preferred method for both industrial and jewelry applications.

Challenges and Considerations

While nitric acid for gold refining is effective, it comes with its own set of challenges. One major concern is the handling of nitric acid, which is a highly corrosive and hazardous chemical. Proper safety protocols and equipment are necessary to manage the risks associated with nitric acid, including protective gear and ventilation systems.

Another consideration is the need for precise control over the refining process. Variations in the concentration of nitric acid or temperature can impact the quality of the final gold product. Therefore, careful monitoring and adjustments are essential to ensure optimal results.

Environmental and Safety Aspects

The use of nitric acid for gold refining also involves environmental and safety considerations. The process generates waste products that need to be managed to minimize environmental impact. Additionally, the fumes produced during the reaction can be harmful if not properly controlled.

To address these concerns, many refining operations are adopting advanced safety measures and environmental management practices. Implementing proper waste treatment and recycling methods helps reduce the ecological footprint of using nitric acid for gold refining. Ensuring adequate ventilation and safety protocols are crucial for protecting both workers and the environment.

Innovations in Nitric Acid for Gold Refining

Recent advancements in the use of nitric acid for gold refining have focused on improving efficiency and safety. Innovations in refining technology aim to enhance the effectiveness of nitric acid while minimizing its environmental impact. For example, new methods for recycling and neutralizing waste products are being developed to make the process more sustainable.

Nitric acid for gold refining is a highly effective method for achieving high-purity gold. Its ability to selectively dissolve impurities makes it a valuable tool in the refining industry. While the process involves careful management of hazardous chemicals and environmental considerations, its advantages in efficiency and purity make it a preferred choice for gold refiners. As technology continues to advance, the use of nitric acid for gold refining will likely evolve, incorporating improvements in safety and sustainability.