nitric acid gold purification

The Role of Nitric Acid in Gold Purification A Comprehensive Guide

Gold has been a symbol of wealth and status since ancient times, and its enduring allure is as much about its aesthetic appeal as it is about its intrinsic value. However, the journey from raw gold ore to gleaming, pure gold involves a series of complex processes, one of which is nitric acid gold purification. This method has become a cornerstone in the metallurgical industry due to its effectiveness in removing impurities. This article explores the intricacies of nitric acid gold purification, shedding light on its significance and the techniques involved.

Understanding Nitric Acid in Metallurgy

Nitric acid (HNO₃) is a powerful oxidizing agent that finds extensive use in various industries, including metallurgy. Its ability to dissolve certain metals, particularly when combined with hydrochloric acid in a process known as aqua regia, makes it invaluable for purifying gold. Aqua regia, meaning “royal water,” earned its name because it was capable of dissolving the “noble” metals, gold and platinum, which were previously considered resistant to corrosion.

The Nitric Acid Gold Purification Process

The process of purifying gold using nitric acid typically involves several stages, each designed to remove specific impurities and enhance the purity of the gold. Here is a breakdown of the key steps:

Initial Dissolution

The first step involves dissolving the gold alloy in a strong acid solution, often a mixture of nitric acid and hydrochloric acid (aqua regia). This combination is effective because nitric acid oxidizes the gold, while hydrochloric acid provides chloride ions that form soluble chloroauric acid (HAuCl₄), thus dissolving the gold.

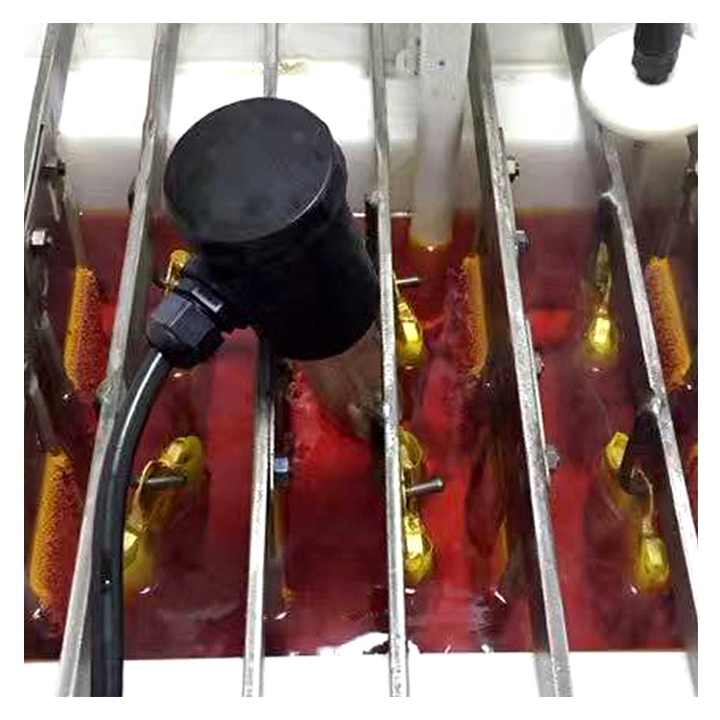

Separation of Impurities

Once the gold has been dissolved, the solution is filtered to remove insoluble impurities. This step is crucial as it helps to isolate the gold from other metals that do not dissolve in the acid solution, such as platinum group metals (PGMs).

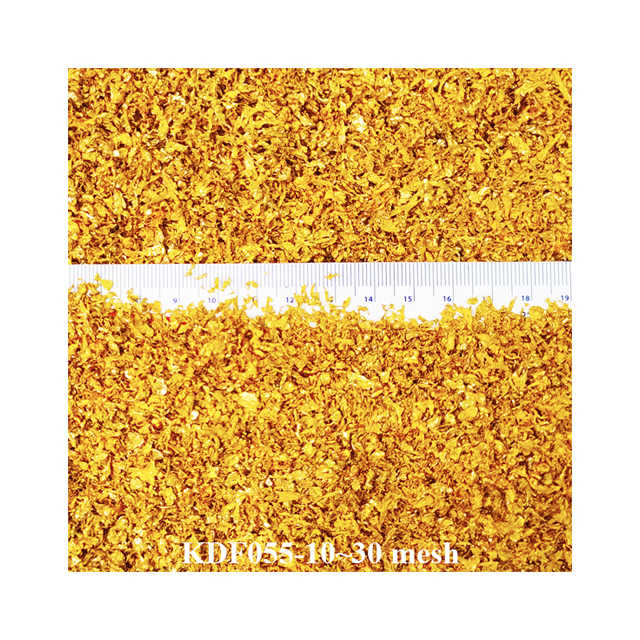

Precipitation and Recovery

After filtering, the next step is to precipitate the gold from the solution. This can be achieved by adding a reducing agent, such as sodium metabisulfite or iron (II) sulfate, which reduces the gold ions back to metallic gold. The precipitated gold is then collected and washed to remove any residual acids or salts.

Final Refining

The recovered gold is often subjected to further refining to achieve the highest levels of purity. Techniques such as electrolytic refining can be employed to remove any remaining impurities, yielding gold that is 99.99% pure or higher.

Advantages and Challenges of Using Nitric Acid

Using nitric acid for gold purification offers several advantages, including its effectiveness in dissolving gold and its relatively low cost compared to other refining agents. However, handling nitric acid requires caution due to its corrosive nature and the toxic fumes it can produce. Proper safety measures and equipment are essential to mitigate risks associated with its use.

Moreover, the environmental impact of using nitric acid in gold purification is a concern that modern metallurgists strive to address. Efforts are underway to develop more sustainable and environmentally friendly alternatives, reflecting a broader trend towards greener metallurgical practices.

The Future of Nitric Acid Gold Purification

As the demand for high-purity gold continues to grow, so too does the need for efficient and sustainable purification methods. Research into optimizing the use of nitric acid and exploring alternative processes that minimize environmental impact promises to shape the future of gold purification. Innovations in this field not only enhance the quality of the final product but also contribute to a more responsible approach to metallurgy.

In summary, the nitric acid gold purification process is a vital component of gold refining, enabling the transformation of raw materials into the pure gold that underpins countless applications—from jewelry to electronics. By understanding the complexities and potential of this process, we gain insight into the intricate balance between tradition and innovation that defines the metallurgical arts.