Process Of Refining Gold Smelting

The Intricacies of the Gold Smelting Process: A Deep Dive into Modern Techniques

Gold smelting is an ancient process used to extract gold from its raw form. Over time, this method has evolved significantly, thanks to advancements in technology and a deeper understanding of metallurgy. Today, FRT Machinery leads the way in providing state-of-the-art solutions for refining gold through smelting. Let’s explore the various stages involved in this transformative process, highlighting how modern machinery and techniques have revolutionized gold smelting.

The Initial Preparation Stage in Gold Smelting

Before the actual smelting process begins, the ore must undergo preparation. This stage involves crushing the raw material to reduce it to smaller particles. FRT Machinery’s specialized crushers are designed to efficiently break down gold-bearing rocks without compromising the purity of the embedded metal. Once crushed, the ore is further refined through grinding processes to ensure all pieces are of uniform size, ready for the next phase of gold smelting.

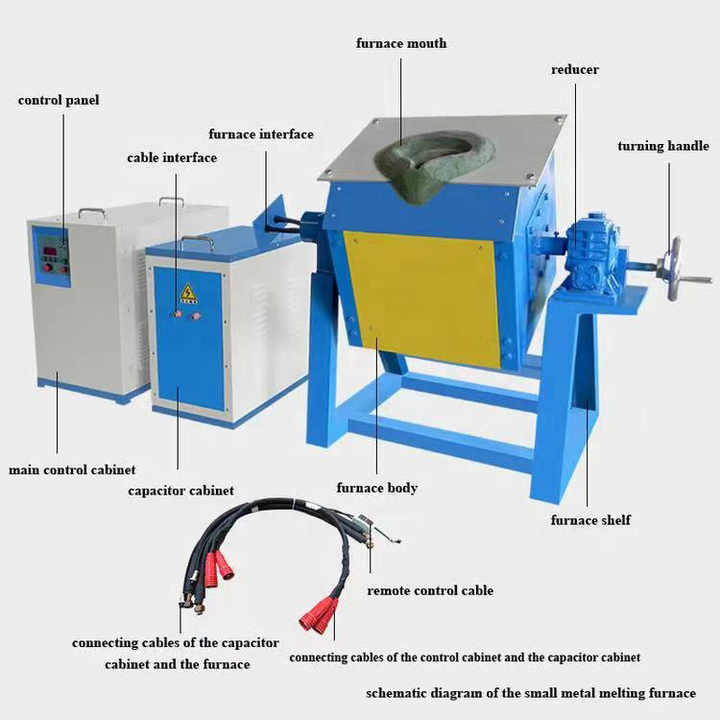

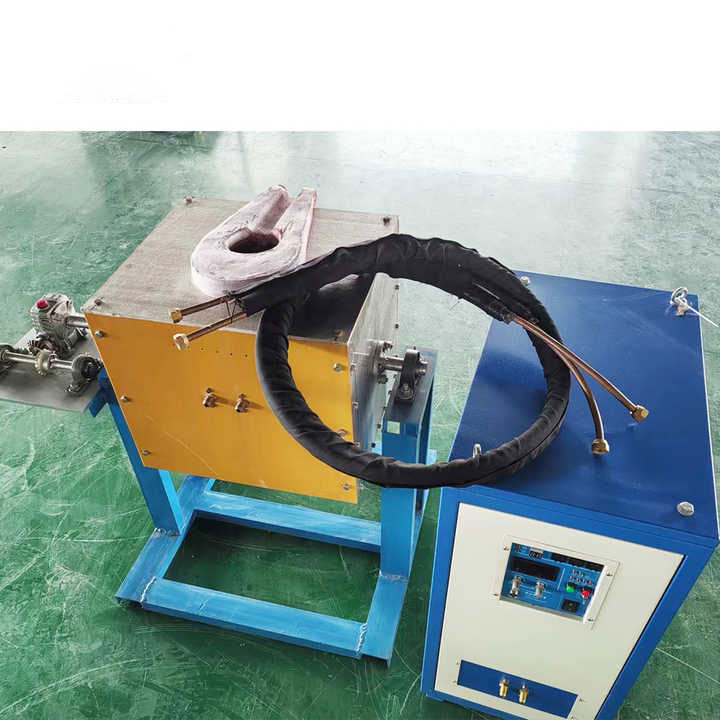

Introduction to the Gold Smelting Furnace

At the heart of gold smelting lies the furnace—a piece of equipment where magic happens. FRT Machinery offers high-temperature furnaces capable of reaching temperatures up to 1,600°C, necessary for melting gold and separating it from impurities. These furnaces utilize advanced insulation materials and energy-efficient designs, ensuring minimal heat loss during operation. The controlled environment within these furnaces facilitates the separation of gold from other elements present in the ore, showcasing the precision engineering required for successful gold smelting.

Flux Addition During Gold Smelting

To enhance the efficiency of the smelting process, fluxes are added to the molten mixture. Fluxes play a crucial role by lowering the melting point of non-metallic impurities, allowing them to separate from the gold more easily. FRT Machinery’s automated systems accurately measure and introduce fluxes such as borax or silica into the furnace, maintaining optimal conditions for purifying gold. This step is critical in ensuring that only pure gold remains once the slag (a waste product) is removed from the furnace.

Refining the Melted Gold Post-Smelting

After smelting, the gold needs further refinement to achieve the desired purity levels. FRT Machinery provides advanced refining technologies that can process the molten gold, removing any remaining impurities. Electrolytic refining and chemical purification methods are commonly employed, depending on the specific requirements of the final product. These processes ensure that the gold meets international standards of purity, making it suitable for various applications ranging from jewelry to industrial uses.

Safety Measures in Gold Smelting Operations

Safety is paramount in any industrial process, especially one involving extreme temperatures like gold smelting. FRT Machinery prioritizes operator safety by incorporating features such as emergency shut-off mechanisms, temperature monitoring systems, and ergonomic designs into their equipment. Training programs are also provided to ensure that personnel understand best practices for handling the machinery safely and efficiently. By focusing on both technological innovation and operational safety, FRT Machinery sets new benchmarks in the gold smelting industry.

Environmental Impact of Modern Gold Smelting

With growing concerns over environmental sustainability, modern gold smelting must address its ecological footprint. FRT Machinery addresses this challenge by developing equipment that minimizes emissions and waste production. Their furnaces feature advanced filtration systems that capture harmful gases before they are released into the atmosphere. Additionally, efforts are made to recycle water and recover valuable metals from slag, reducing the overall environmental impact of gold smelting operations.

By combining cutting-edge technology with sustainable practices, FRT Machinery demonstrates a commitment to advancing the field of gold smelting while promoting responsible resource management. As we continue to innovate, the future of gold smelting looks brighter than ever before.