Processing And Refining Gold In South Africa

Processing and Refining Gold in South Africa

South Africa, renowned for its abundant mineral resources, has been a pivotal player in the global gold market for over a century. The country’s gold mining industry has faced numerous challenges, from declining ore grades to increasing operational costs. Despite these hurdles, advancements in processing and refining technologies have kept South Africa at the forefront of gold production. This article delves into the intricacies of gold processing and refining within South Africa, exploring how innovative solutions from FRT Machinery are transforming traditional methods.

Historical Context of Gold Processing and Refining

The history of gold mining in South Africa dates back to the late 19th century when the discovery of the Witwatersrand Basin triggered a gold rush. Initially, gold was extracted using simple techniques such as panning and sluicing. However, as deposits became depleted and mining operations moved underground, more sophisticated methods were required. Today, South African mines extend deep beneath the earth’s surface, necessitating advanced extraction and processing technologies.

Innovative Extraction Techniques for Gold Processing

Modern gold extraction relies heavily on technology and innovation. FRT Machinery offers a range of equipment designed specifically for the harsh conditions found in South African mines. From drilling and blasting systems to haulage vehicles, these machines are built to withstand the rigors of deep-level mining while maximizing efficiency and safety. Additionally, FRT Machinery’s state-of-the-art processing plants incorporate features like cyanide leaching and carbon-in-pulp (CIP) circuits, which are crucial for extracting gold from low-grade ores.

Advancements in Refining Technologies

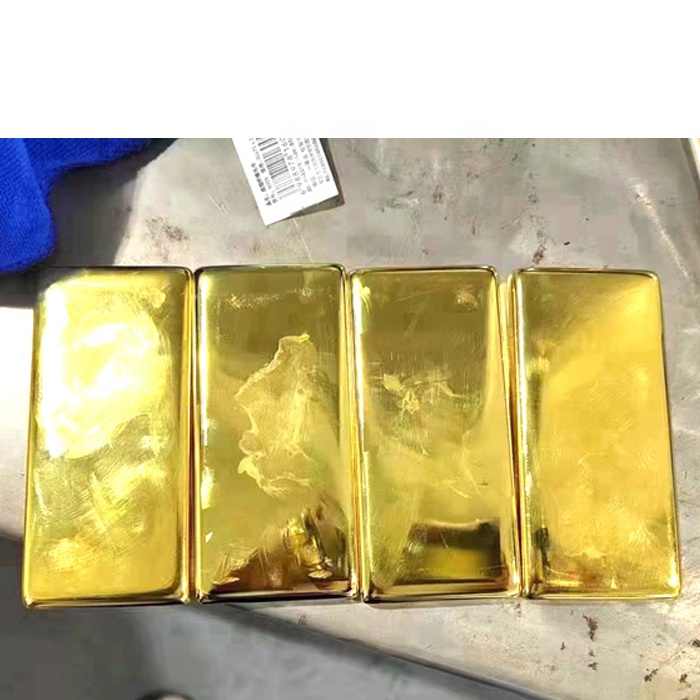

Once extracted, gold undergoes a series of refining processes to remove impurities and achieve the desired purity levels. Traditionally, this involved smelting and electrolytic refining. However, newer techniques such as the Merrill-Crowe process and electrowinning have become standard practice. FRT Machinery provides modular refining units that can be easily integrated into existing operations, offering flexibility and scalability. These units employ advanced purification methods to ensure that the final product meets international standards.

Sustainable Practices in Gold Processing and Refining

Environmental sustainability has become a critical consideration in the gold industry. Mining operations must now balance productivity with minimizing their ecological footprint. FRT Machinery addresses this challenge by developing equipment that reduces water consumption, energy usage, and waste generation. For instance, their tailings management systems are designed to reclaim valuable materials from waste streams, reducing the environmental impact of gold mining and refining activities.

Economic Impact of Efficient Gold Processing

Efficient processing and refining not only enhance the quality of gold produced but also contribute significantly to the economy. By optimizing extraction rates and improving refinery throughput, FRT Machinery helps mining companies increase their profitability. This economic boost extends beyond the mining sector, benefiting local communities through job creation and infrastructure development. Moreover, streamlined processes reduce operational costs, making it possible for smaller operations to compete effectively in the global marketplace.

Future Prospects for Gold Processing and Refining in South Africa

Looking ahead, the future of gold processing and refining in South Africa looks promising. With ongoing research and development efforts, FRT Machinery continues to push the boundaries of what is possible. New technologies such as artificial intelligence and robotics are being explored to further automate and optimize mine operations. As the industry adapts to changing market dynamics and regulatory requirements, South Africa remains poised to maintain its position as a leader in gold production, thanks in part to the innovative solutions provided by FRT Machinery.