purification of gold and silver

Purification of Gold and Silver Techniques and Methods

The purification of gold and silver has been a significant practice for centuries, essential for ensuring the metals’ quality and usability. The process involves removing impurities and refining the metals to their purest form. This article will explore the various methods used in the purification of both gold and silver, the science behind these methods, and their importance in today’s industries.

1. The Importance of Gold and Silver Purification

Gold and silver are valuable metals, but they are rarely found in their purest form in nature. When mined, they often contain impurities such as copper, lead, zinc, or other base metals. The purification of gold and silver ensures that the metals are separated from these impurities, allowing for higher value and more efficient use in industries such as jewelry, electronics, and investments.

2. Historical Methods for Purification of Gold and Silver

Historically, methods for purifying gold and silver have evolved over time, starting with simple physical separation techniques and gradually incorporating chemical processes.

2.1. Cupellation

Cupellation is one of the earliest techniques used for the purification of gold and silver. This process involves heating the metal to a high temperature in a special furnace while blowing air over it. The impurities oxidize and are absorbed by a porous substance called the “cupel,” leaving behind pure gold or silver.

2.2. Fire Assay

Fire assay is another ancient technique used primarily for gold but also effective in silver refining. This method involves melting the ore in a furnace with lead, which binds with impurities. Once the lead melts away, the remaining pure gold or silver can be collected.

3. Modern Methods for Purification of Gold and Silver

Today, various modern methods have replaced the ancient techniques, making the purification process more efficient, precise, and environmentally friendly. These methods use advanced chemistry and technology to achieve high purity levels for both gold and silver.

3.1. The Aqua Regia Process

Aqua regia, a powerful combination of nitric acid and hydrochloric acid, is used in the purification of gold and silver. This method is highly effective at dissolving both gold and silver, allowing impurities to be separated and filtered out. Aqua regia is especially popular for refining gold, as it dissolves the gold into a solution from which it can be precipitated in a purified form.

How Aqua Regia Purifies Gold and Silver

The gold or silver is dissolved in the acid solution, which reacts with the impurities. Once the unwanted metals are removed, the pure gold or silver is precipitated out using a reducing agent, leaving the metals in their purest form.

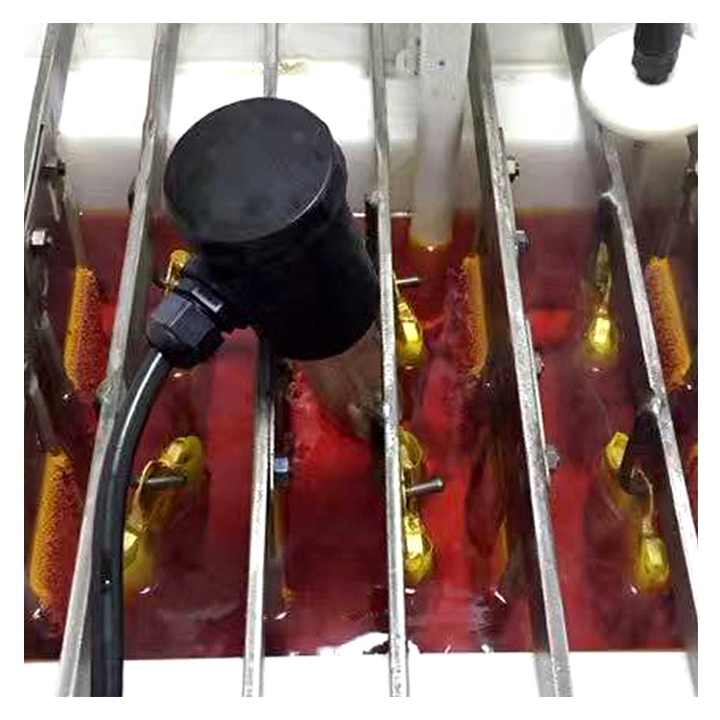

3.2. Electrolytic Refining

Electrolytic refining is one of the most precise modern techniques for the purification of gold and silver. In this process, the impure metals are placed in an electrolyte solution, and an electric current is applied. This causes the pure metals to deposit onto a cathode, while the impurities are left behind in the solution.

Benefits of Electrolytic Refining

Electrolytic refining provides very high levels of purity, with gold and silver reaching up to 99.99% purity. This method is highly efficient and is widely used in industries where precision and purity are critical, such as electronics and investment-grade bullion.

3.3. The Miller Process for Gold

The Miller process is commonly used for the purification of gold, though it is less frequently applied to silver. In this process, chlorine gas is passed through molten gold, causing impurities to form chloride compounds that float to the surface, where they can be removed.

Limitations of the Miller Process

Although the Miller process is faster than other refining methods, it is not as effective in producing ultra-pure gold. As such, it is often used as a preliminary step before further refining through processes like electrolytic refining.

3.4. The Parkes Process for Silver

The Parkes process is a technique used to refine silver from lead ores. In this process, zinc is added to the molten lead containing silver. The zinc binds with the silver, forming a layer that can be skimmed off, leaving behind pure silver.

Efficiency of the Parkes Process

The Parkes process is highly effective for refining silver from lead-based ores and is commonly used in large-scale industrial silver purification.

4. The Role of Chemicals in Gold and Silver Purification

Chemicals play an essential role in many purification of gold and silver methods, especially in modern refining techniques.

4.1. Use of Acids

Acids such as nitric acid, hydrochloric acid, and sulfuric acid are commonly used in various refining methods. These acids help dissolve the metal, allowing impurities to be filtered out.

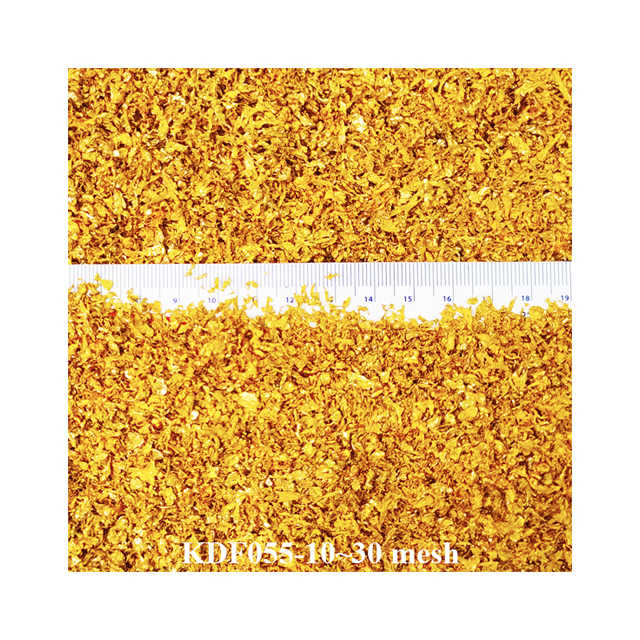

4.2. The Wohlwill Process for Gold

The Wohlwill process is an electrochemical process used for refining gold to its highest level of purity, often reaching 99.999%. This process involves placing the impure gold in an electrolyte solution and applying an electric current to separate the pure gold from impurities.

4.3. Cyanidation

Cyanidation is another chemical process used primarily for gold but sometimes for silver purification. In this process, the metal is dissolved in a cyanide solution, which helps separate gold or silver from the ore. The metal is then recovered from the solution using activated carbon or zinc.

5. Environmental Impact of Gold and Silver Purification

The purification of gold and silver can have significant environmental impacts, particularly when chemicals like acids and cyanide are involved. However, modern techniques have been developed to reduce these impacts.

5.1. Waste Reduction

Many modern methods are designed to minimize waste and reduce the environmental footprint of refining processes. For example, electrolytic refining produces less waste compared to traditional methods like smelting and cupellation.

5.2. Recycled Metals

Increasingly, gold and silver refiners are turning to recycled metals to reduce the need for mining and minimize environmental harm. Recycling allows for the purification of gold and silver without the environmental destruction caused by mining.

The purification of gold and silver has evolved significantly from ancient methods to modern techniques. While traditional methods like cupellation and fire assay are still in use, modern processes such as aqua regia, electrolytic refining, and the Wohlwill process provide more efficient and environmentally friendly ways to achieve high purity levels. These advancements in purification techniques ensure that both gold and silver continue to be valuable and versatile metals in today’s industries.