purification of gold by electrolysis

Introduction to the Purification of Gold by Electrolysis

The purification of gold by electrolysis is a widely used method in the precious metals industry, offering a reliable and efficient way to refine gold to high purity levels. Electrolysis is a chemical process that uses an electrical current to separate pure gold from impurities, resulting in gold that is suitable for various industrial, commercial, and investment purposes. This article explores the steps involved in the purification of gold by electrolysis and highlights its advantages over other refining methods.

The Basics of Electrolytic Gold Purification

The purification of gold by electrolysis works on the principle of using electricity to drive a chemical reaction that separates gold from impurities. In this process, impure gold is dissolved in an electrolytic solution, and pure gold is deposited onto a cathode, leaving impurities behind.

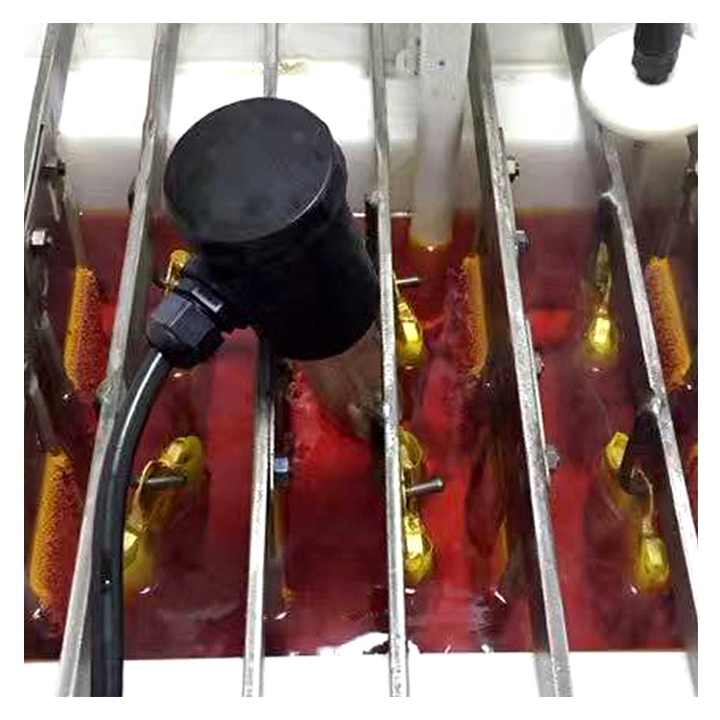

Setting Up the Electrolytic Cell

The first step in the purification of gold by electrolysis involves setting up the electrolytic cell. The cell consists of two electrodes: the anode, made of impure gold, and the cathode, which is a thin strip of pure gold or another conductive material. These electrodes are placed in an electrolytic solution, typically a mixture of hydrochloric acid and gold chloride, which acts as the electrolyte.

Electrolysis Process

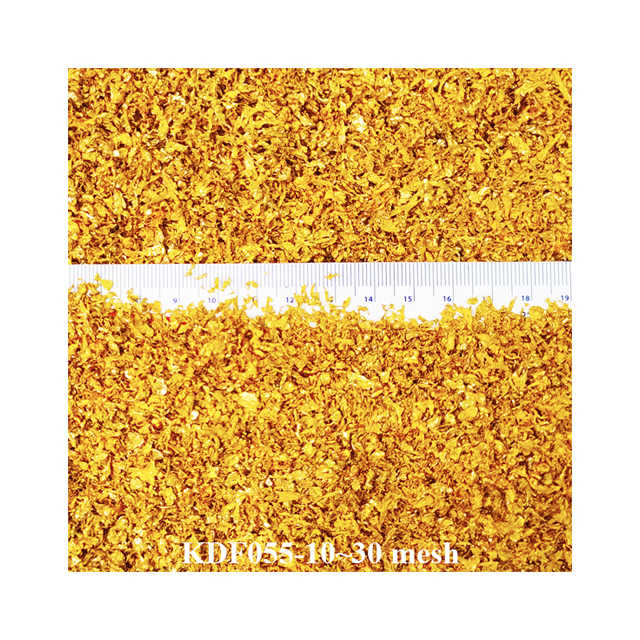

Once the electrolytic cell is set up, an electrical current is passed through the solution. At the anode, the impure gold dissolves into the electrolyte, releasing gold ions. These ions are attracted to the cathode, where they are reduced to form pure gold, which gradually accumulates on the cathode. Impurities such as silver, copper, and other base metals remain in the electrolyte or form a sludge at the bottom of the cell.

Advantages of Purification of Gold by Electrolysis

The purification of gold by electrolysis offers several advantages over other methods of gold refining, making it a preferred technique in many industrial applications.

High Purity Levels

One of the primary benefits of using electrolysis for gold purification is the ability to achieve extremely high levels of purity. This method can produce gold that is 99.99% pure, which is essential for applications that require the highest standards, such as in electronics and fine jewelry.

Efficiency and Cost-Effectiveness

The purification of gold by electrolysis is highly efficient, requiring relatively low energy input compared to traditional methods like smelting. Additionally, the process can be automated, reducing labor costs and increasing production speed. These factors make electrolysis a cost-effective option for large-scale gold refining operations.

Environmental Benefits

Compared to other gold refining methods, the purification of gold by electrolysis is considered more environmentally friendly. It generates less toxic waste and reduces the release of harmful gases, such as sulfur dioxide, which are common byproducts of smelting. This makes electrolysis a more sustainable option for gold purification, particularly in industrial settings.

Applications of Electrolytic Gold Purification

The purification of gold by electrolysis has various applications in industries where high-purity gold is essential.

Electronics and Electrical Components

The electronics industry relies heavily on the purification of gold by electrolysis to produce gold with the purity required for electrical components, such as connectors and circuit boards. Gold’s excellent conductivity and resistance to corrosion make it a valuable material in electronics manufacturing.

Fine Jewelry and Bullion

In the jewelry industry, the purification of gold by electrolysis ensures that the gold used in crafting fine jewelry meets the highest purity standards. Likewise, gold bullion produced for investment purposes often undergoes electrolysis to achieve the purity demanded by investors and markets.

Industrial Applications

Gold is used in various industrial applications, including in medical devices, aerospace components, and catalytic converters. The purification of gold by electrolysis ensures that the gold used in these applications is of the highest possible quality, meeting the stringent requirements of each industry.

Limitations of the Electrolysis Method

Despite its many advantages, the purification of gold by electrolysis also has some limitations.

Initial Setup Costs

The initial investment required to set up an electrolytic refining system can be relatively high. This includes the cost of purchasing specialized equipment, such as electrolytic cells and power supplies. However, these costs are often offset by the long-term benefits of increased efficiency and reduced operational expenses.

Handling and Disposal of Electrolytes

The electrolytic process requires the use of potentially hazardous chemicals, such as hydrochloric acid. Proper handling, storage, and disposal of these chemicals are essential to ensure the safety of workers and minimize environmental impact. Companies must implement strict protocols to manage these substances responsibly.

The purification of gold by electrolysis is a highly effective and efficient method for refining gold to high purity levels. Its ability to produce gold with minimal environmental impact, coupled with its cost-effectiveness and industrial applications, makes it a preferred method in the precious metals industry. While it requires careful handling and an initial investment in specialized equipment, the benefits of this process make it a valuable technique for refining gold at both large and small scales.