Refining Charge Gold

Refining Charge Gold: Techniques and Technologies

In the dynamic landscape of precious metal processing, refining charge gold stands out as a critical procedure aimed at purifying and enhancing the quality of gold. This process is fundamental for transforming raw, impure forms of gold into high-purity products suitable for various applications, from jewelry to industrial uses. As experts in this field, FRT Machinery has developed advanced technologies specifically designed to optimize the efficiency and effectiveness of refining charge gold. Let’s delve deeper into the methodologies, challenges, and innovations surrounding this essential process.

Understanding the Basics of Refining Charge Gold

Before diving into the specifics, it’s crucial to understand what refining charge gold entails. Essentially, it involves treating raw or scrap gold to remove impurities and enhance its purity level. The goal is to achieve a product that meets the stringent standards required by different industries. FRT Machinery offers a range of solutions tailored to meet these demands, ensuring that each step in the refining process is meticulously controlled and monitored.

FRT Machinery’s Role in Enhancing Refining Charge Gold Processes

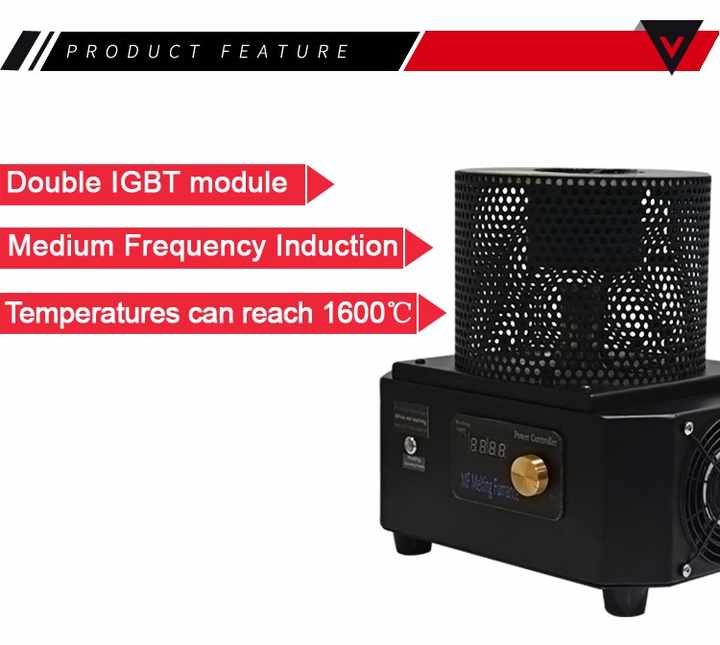

FRT Machinery has been at the forefront of innovation within the gold refining sector. Our commitment to research and development has led to the creation of cutting-edge machinery that streamlines the refining charge gold process while maintaining the highest levels of safety and environmental responsibility. By integrating automation and smart technology, our systems provide unparalleled precision and reliability, making them indispensable tools for modern gold refineries.

Key Steps Involved in the Refining Charge Gold Procedure

The refining charge gold procedure typically includes several key steps:

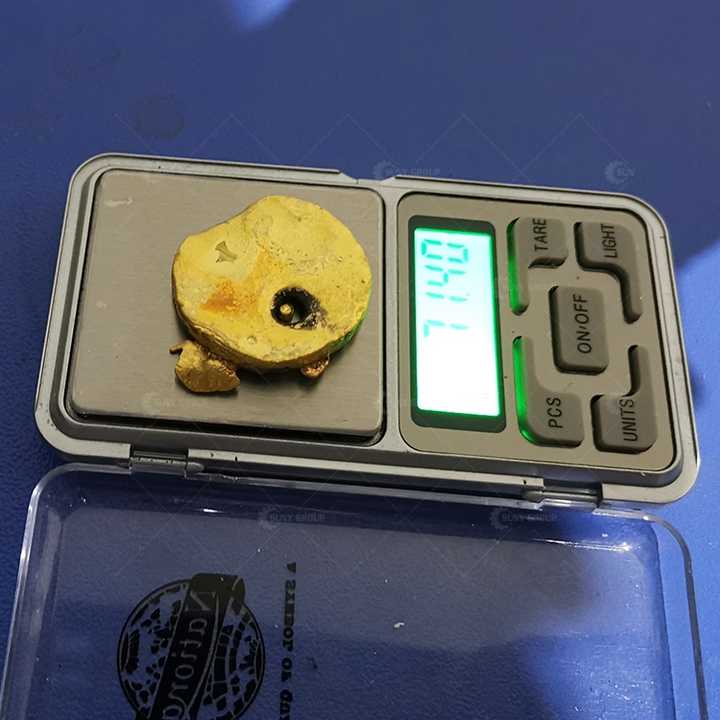

1.Smelting: This initial stage involves melting down the raw material to separate it from non-metallic components.

2.Electrolysis: In this step, electric currents are used to further purify the molten gold, stripping away remaining impurities.

3.Chemical Treatment: Certain chemicals may be added to react with specific impurities, allowing for their removal.

4.Polishing and Finishing: Once purified, the gold undergoes final treatments to achieve the desired finish and form.

Each of these stages requires specialized equipment and expertise, areas where FRT Machinery excels, providing comprehensive solutions that cover the entire spectrum of refining charge gold operations.

Advantages of Using FRT Machinery for Refining Charge Gold

Choosing FRT Machinery for your refining charge gold needs comes with numerous benefits. Our machinery is designed with efficiency, durability, and ease-of-use in mind, ensuring that every aspect of the refining process is handled with utmost precision. Moreover, we prioritize sustainability, incorporating features that minimize waste and reduce environmental impact. Whether you’re looking to upgrade existing facilities or establish new ones, partnering with FRT Machinery guarantees state-of-the-art solutions backed by industry-leading support and service.

Challenges in Refining Charge Gold and How FRT Machinery Addresses Them

Despite advancements, refining charge gold continues to face challenges such as fluctuating gold prices, stringent environmental regulations, and the need for continuous technological upgrades. FRT Machinery tackles these issues head-on through ongoing innovation and collaboration with industry leaders. We focus on developing scalable, adaptable solutions that can evolve alongside changing market conditions and regulatory requirements, ensuring that our clients remain competitive and compliant.

Future Trends in Refining Charge Gold Technology

Looking ahead, the future of refining charge gold is likely to be shaped by emerging technologies such as artificial intelligence (AI) and machine learning (ML). These innovations promise to revolutionize how processes are managed, potentially leading to even more efficient and sustainable refining methods. As pioneers in this field, FRT Machinery is committed to exploring and integrating these technologies, setting new benchmarks for excellence in refining charge gold practices.

By embracing the latest advancements and maintaining a forward-thinking approach, FRT Machinery remains dedicated to driving progress within the gold refining industry. Our comprehensive suite of solutions, combined with a deep understanding of customer needs, positions us as a trusted partner for all your refining charge gold requirements.