Refining Gold Dross

Refining Gold Dross: Enhancing Value Through Precision

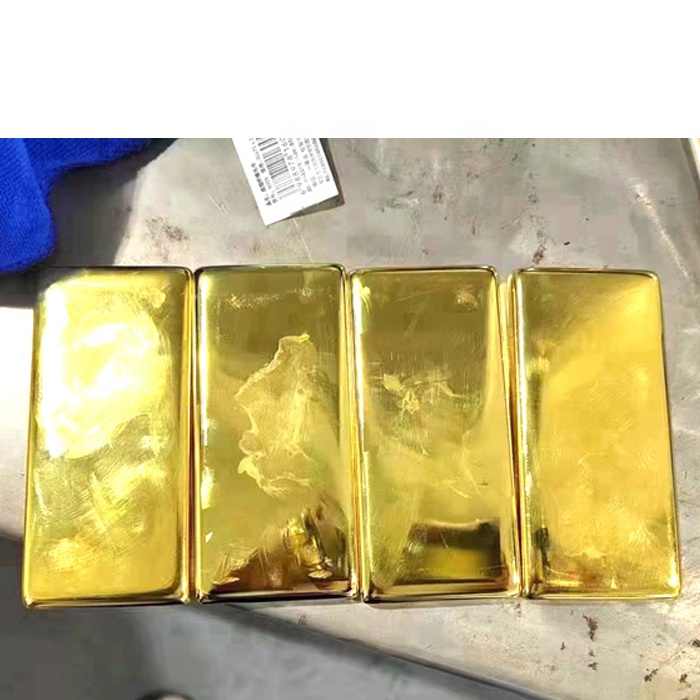

Gold dross, a by-product generated during the smelting and refining processes of gold, contains valuable metals such as gold and silver. It also includes other elements like lead, zinc, and copper. The process of refining gold dross is critical for recovering these precious metals efficiently and sustainably. This article will explore the intricacies of refining gold dross, focusing on the techniques and technologies used to maximize recovery rates and minimize environmental impact.

Gold Dross Refining: A Fundamental Process

The initial stages of refining gold dross involve separating it from other residues and slag materials. This separation is crucial as it ensures that the subsequent refining processes focus solely on the material rich in precious metals. FRT Machinery offers advanced dross separation systems designed to enhance this step, ensuring that only high-quality dross moves forward in the refining sequence.

Techniques for Processing Gold Dross

Several techniques are employed in the processing of gold dross, each tailored to specific conditions and requirements. Among these methods, hydrometallurgical and pyrometallurgical processes stand out due to their efficiency and effectiveness. Hydrometallurgy involves using aqueous solutions to extract metals, whereas pyrometallurgy relies on high temperatures. FRT Machinery’s specialized equipment supports both methodologies, providing versatile solutions for diverse refining needs.

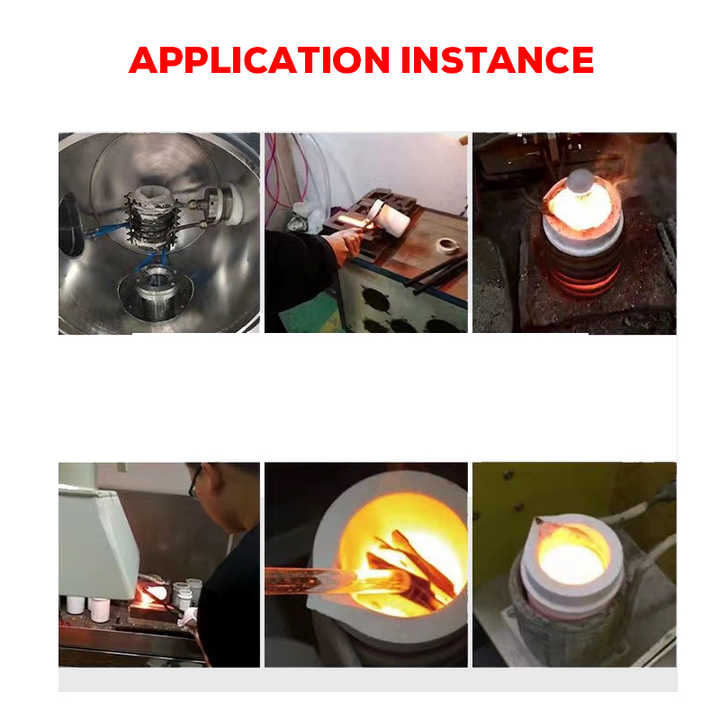

Equipment for Efficient Gold Dross Refining

To achieve optimal results in gold dross refining, employing the right equipment is essential. FRT Machinery provides a range of machinery specifically designed for this purpose. These include dross skimming machines, which remove dross from molten metal surfaces, and dross melting furnaces, which facilitate the melting and separation of valuable metals from the dross. Each piece of equipment is engineered to enhance the refining process, ensuring higher recovery rates and improved operational efficiency.

Environmental Considerations in Refining Gold Dross

Environmental sustainability is a key aspect of modern gold dross refining practices. Processes must be designed not only to maximize metal recovery but also to minimize waste and reduce emissions. FRT Machinery’s systems incorporate features that help manage environmental impacts, such as efficient filtration units and emission control technologies. By adopting these sustainable practices, refineries can contribute positively to both economic and ecological goals.

The Role of Technology in Modernizing Refining Practices

Advancements in technology have significantly impacted the way gold dross is refined today. Automation and digital monitoring systems, for instance, play a pivotal role in enhancing the precision and consistency of refining operations. FRT Machinery integrates state-of-the-art technological innovations into its machinery, enabling real-time data analysis and adjustments that improve overall refining performance. This technology-driven approach ensures that every step of the refining process is optimized for maximum efficiency.

Future Trends in Gold Dross Refining

Looking ahead, the future of gold dross refining promises further innovation and refinement of existing techniques. Research is ongoing to develop even more sustainable and cost-effective methods. As industry leaders, FRT Machinery continues to invest in research and development, aiming to bring cutting-edge solutions to market that will shape the future of gold dross refining.

Through a combination of innovative technologies, sustainable practices, and a commitment to excellence, FRT Machinery is setting new standards in gold dross refining. Whether you are looking to upgrade your current refining setup or establish a new operation, FRT Machinery offers comprehensive solutions designed to meet your specific needs and exceed your expectations.