refining gold dust

Refining gold dust is a critical process in the gold recovery and jewelry-making industries. This article delves into the methods, significance, and steps involved in refining gold dust to ensure that you understand both the practical aspects and the underlying principles.

Understanding Gold Dust

Gold dust typically refers to tiny particles of gold that are often a byproduct of mining and processing ore. Unlike larger gold nuggets, gold dust can be challenging to handle due to its fine nature. Its value lies in its purity and the potential it holds when refined correctly.

The Importance of Refining Gold Dust

Refining gold dust is essential for several reasons:

- Purity: The refinement process increases the purity of gold, removing impurities and other metals.

- Value: Pure gold has a significantly higher market value compared to impure gold dust.

- Usability: Refined gold can be easily melted and shaped for various applications, from jewelry to electronics.

Methods of Refining Gold Dust

There are several methods used to refine gold dust, each with its advantages and applications:

Chemical Refining

Chemical refining involves the use of chemicals to separate gold from impurities. One common method is the use of aqua regia, a mixture of hydrochloric and nitric acids. This method effectively dissolves gold, allowing for the separation of other metals. After dissolution, gold can be precipitated out using various chemicals, resulting in a purer form.

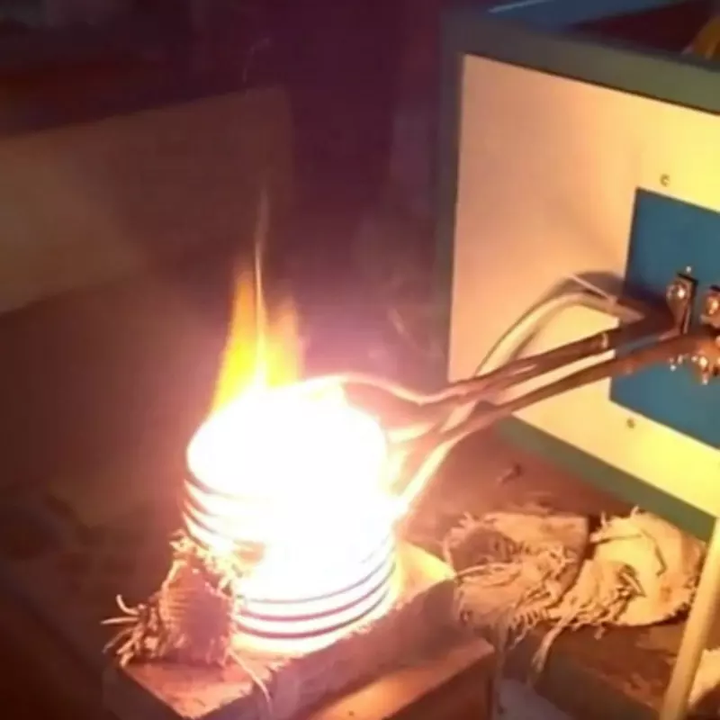

Fire Refining

Fire refining is another traditional method used to purify gold. This involves heating gold dust in a crucible until it melts. During this process, impurities rise to the surface and can be removed as slag. Fire refining is particularly useful for larger quantities of gold dust and is widely used in industrial applications.

Electrolytic Refining

Electrolytic refining uses an electrolytic cell to refine gold dust. In this method, a solution containing gold ions is electrolyzed, allowing pure gold to be deposited onto a cathode. This method is known for producing very high-purity gold and is often used in commercial gold refining operations.

The Refining Process

The refining process generally involves several key steps:

- Collection and Preparation: Gather the gold dust and prepare it for refining. This may include drying and removing any debris.

- Selection of Refining Method: Choose the appropriate method based on the desired purity level and available equipment.

- Refining: Apply the chosen refining method. For chemical refining, this would involve dissolving the gold dust; for fire refining, melting it; or for electrolytic refining, setting up the electrolytic cell.

- Precipitation or Separation: After refining, separate the pure gold from impurities. This step may involve chemical reactions or physical processes, depending on the method used.

- Collection of Pure Gold: Finally, collect the refined gold. This can be shaped into bars, coins, or other forms as required.

Safety Precautions

Refining gold dust can involve hazardous materials and high temperatures. It is essential to take safety precautions, including:

- Wearing protective gear, such as gloves and goggles.

- Working in a well-ventilated area to avoid inhaling harmful fumes.

- Following all safety guidelines related to the chemicals and equipment used.

Refining gold dust is a vital process that enhances the value and usability of gold. By understanding the various methods and the steps involved, individuals and businesses can effectively refine gold dust to achieve high-purity results. Whether through chemical methods, fire refining, or electrolytic techniques, the refinement process transforms raw materials into valuable assets, making it an essential practice in the gold industry.