refining gold ore

Refining Gold Ore: A Comprehensive Guide

Refining gold ore is an essential step in the process of extracting pure gold from raw materials. Whether you’re working with gold ore mined from the earth or scrap gold, the refining process is crucial to obtaining high-quality gold for use in various industries, including jewelry making, electronics, and investment products. In this article, we will discuss the steps involved in refining gold ore and the various methods used to ensure the highest level of purity.

Understanding Gold Ore

Gold ore is a naturally occurring material that contains traces of gold. It is typically found in veins within rock formations, often mixed with other elements such as quartz, sulfur, and various metals. The amount of gold in the ore varies significantly, so the refining process is essential for extracting as much gold as possible.

The refining process involves separating the gold from the surrounding materials, purifying it, and preparing it for further use. The goal is to eliminate all impurities to achieve 99.9% pure gold, also known as 24-karat gold.

Methods of Refining Gold Ore

There are several methods to refine gold ore, depending on the quality of the ore and the desired purity level. Below are some of the most common techniques used in gold refining:

1. The Miller Process

The Miller process is one of the simplest and fastest methods for refining gold ore. It involves introducing chlorine gas to the molten gold, causing the impurities to form a slag on the surface. This method typically results in gold with a purity of about 99.5%, which is sufficient for many industrial applications. However, it may not be ideal for producing the highest purity levels.

2. The Wohlwill Process

The Wohlwill process is a more advanced method that is used to refine gold to a higher purity, usually 99.99%. It is an electrolytic process, where the impure gold is dissolved in a solution, and then pure gold is deposited onto electrodes. This method is slower and more expensive than the Miller process, but it produces gold of superior quality.

3. Cupellation

Cupellation is a traditional method used for refining gold ore. It involves heating the ore in a furnace with a porous container called a cupel, which absorbs lead and other base metals from the gold. This process is commonly used in assaying small quantities of gold to determine its purity and value.

4. Aqua Regia Process

The Aqua Regia process is a chemical method that dissolves gold in a mixture of hydrochloric and nitric acids. The solution is then treated to precipitate the gold and remove impurities. This method is often used in refining scrap gold but can also be applied to gold ore. It produces gold of very high purity, making it ideal for applications where extremely pure gold is required.

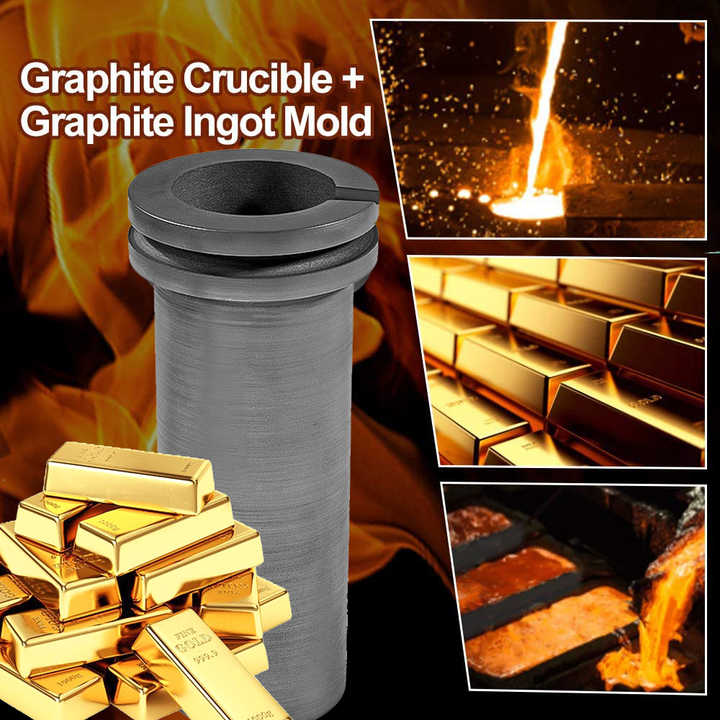

5. Smelting

Smelting is another common method for refining gold ore, where the ore is heated to high temperatures in a furnace. The heat causes the gold to separate from the other materials in the ore. The molten gold is then poured into molds to cool and solidify into bars. This method is typically used for low-grade gold ore and is less precise than chemical refining techniques.

Steps in Refining Gold Ore

The refining of gold ore usually follows these steps:

Step 1: Crushing and Grinding

The first step in the refining process is to crush and grind the gold ore into smaller particles. This increases the surface area of the ore, allowing for easier extraction of gold during the refining process.

Step 2: Concentration

After crushing, the ore is concentrated to remove unwanted materials. Techniques such as flotation, gravity separation, or leaching may be used to separate the gold from other elements.

Step 3: Refining

Once the gold has been concentrated, it undergoes one of the refining methods mentioned above, such as smelting or chemical refining, to purify the gold. During this stage, the goal is to remove all impurities and obtain gold with the highest possible purity.

Step 4: Purification and Finalization

In the final stage, the gold is purified further if necessary. For example, gold refined using the Miller process may undergo the Wohlwill process for additional purification. Once the gold is fully refined, it is molded into bars or other forms for commercial use.

Applications of Refined Gold

Refined gold has numerous applications across various industries:

- Jewelry making: Gold’s durability, beauty, and malleability make it a top choice for crafting fine jewelry.

- Electronics: Gold is an excellent conductor of electricity and is used in connectors, switches, and circuit boards.

- Investment: Refined gold is sold in the form of bars, coins, and other assets, serving as a stable investment in times of economic uncertainty.

- Dentistry and medicine: Gold is biocompatible, meaning it doesn’t react with the human body, making it suitable for use in dental fillings and certain medical devices.

Refining gold ore is a complex and vital process that transforms raw materials into high-purity gold suitable for use in a variety of industries. Whether using traditional methods like cupellation or more modern techniques such as the Wohlwill process, the goal is always the same: to extract as much gold as possible while ensuring its purity. Understanding the methods and steps involved in refining gold ore is essential for anyone working in the gold industry or looking to invest in precious metals.