refining gold with borax

Refining Gold with Borax: A Safer Alternative

Refining gold with borax is an innovative method that has been gaining popularity among small-scale gold miners as a safer and more environmentally friendly alternative to traditional techniques. This process allows gold to be extracted and refined without the use of toxic chemicals like mercury, which is often harmful to both the environment and human health. In this article, we will explore how borax is used in refining gold, its benefits, and the process involved in using this method.

What Is Borax?

Borax is a naturally occurring mineral, also known as sodium borate, that is widely used in various household and industrial applications, including as a cleaning agent, a flux in metalworking, and a preservative. In gold refining, borax acts as a flux that helps to purify the metal by separating impurities from the gold during the smelting process.

Why Use Borax in Gold Refining?

Traditional gold refining methods often rely on mercury or cyanide, both of which pose significant risks to health and the environment. Mercury, in particular, is a neurotoxin that can cause serious health problems when inhaled or ingested, and it contaminates water sources and ecosystems. In contrast, refining gold with borax offers several benefits:

- Safer for human health: Borax is a much safer alternative to mercury, as it is non-toxic and does not release harmful fumes.

- Environmentally friendly: Using borax reduces the release of harmful chemicals into the environment, helping to prevent pollution and ecosystem damage.

- Cost-effective: Borax is inexpensive and widely available, making it a cost-effective solution for small-scale gold miners.

- Efficient: Refining gold with borax can yield high-purity gold, often reaching a level of 99% purity, similar to other methods.

The Process of Refining Gold with Borax

The process of refining gold with borax involves a few straightforward steps that can be done on a small scale without the need for specialized equipment. Here is a general overview of the procedure:

Step 1: Collecting and Preparing the Gold Ore

The first step is to collect the gold ore or gold concentrate. The ore is usually extracted from mining sites and contains both gold and various impurities such as dirt, rocks, and other minerals. The collected ore is then crushed into smaller pieces to increase the surface area for better extraction.

Step 2: Mixing with Borax

Once the ore is crushed, it is mixed with borax. Borax serves as a flux, helping to lower the melting point of gold and allowing impurities to separate more easily from the precious metal during the heating process.

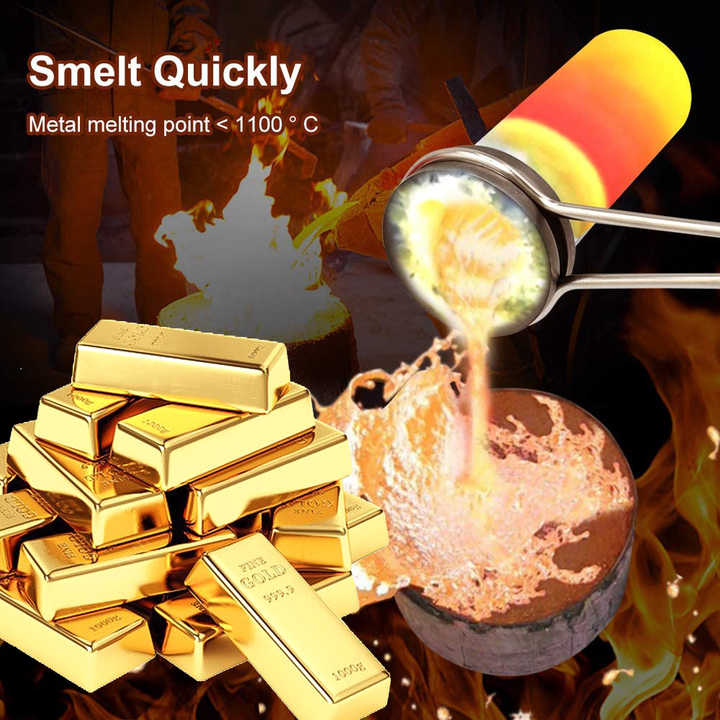

Step 3: Heating and Smelting

The mixture of gold ore and borax is then placed in a crucible or smelting pot and heated to high temperatures, usually around 1,000 to 1,200 degrees Celsius (1,832 to 2,192 degrees Fahrenheit). As the mixture melts, the borax helps to draw out the impurities, which form a slag that floats to the surface. The gold, being heavier, sinks to the bottom of the crucible.

Step 4: Removing the Slag

Once the gold and slag have separated, the slag (containing the impurities) is carefully removed from the surface. What remains in the crucible is the purified molten gold.

Step 5: Cooling and Final Processing

The molten gold is then poured into molds and allowed to cool and solidify. After cooling, the gold can be further purified if necessary, but in many cases, the gold is already pure enough for various applications.

Advantages of Refining Gold with Borax

There are several reasons why refining gold with borax has become a preferred method among small-scale miners:

- Eliminates the use of mercury: By replacing mercury with borax, miners can significantly reduce their exposure to harmful toxins and protect their health.

- More environmentally sustainable: Borax is far less damaging to the environment than mercury or cyanide, as it does not leach into water sources or cause long-term environmental harm.

- Increased gold recovery: Borax can help miners recover more gold from their ore, leading to higher yields and better profitability.

- Cost-effective and accessible: Borax is readily available in many parts of the world and is an inexpensive material, making it a practical solution for small-scale operations.

Refining gold with borax is a simple, effective, and environmentally friendly method that allows small-scale miners to safely extract and purify gold without the use of toxic chemicals. This technique not only provides a safer working environment but also helps reduce environmental pollution. As awareness of the harmful effects of mercury grows, more miners are adopting the borax method, helping to make the gold refining process more sustainable for the future.