refining gold without chemicals

Refining Gold Without Chemicals: An Eco-Friendly Approach

Gold refining is a process that typically involves the use of chemicals to extract pure gold from ore, scrap, or other sources. However, there is growing interest in refining gold without chemicals due to environmental and health concerns. The traditional methods involve toxic substances like cyanide and mercury, which can have harmful effects on both the environment and human health. Fortunately, alternative methods are being explored to make gold refining more sustainable and eco-friendly.

Why Avoid Chemicals in Gold Refining?

- Environmental Concerns

The use of chemicals such as cyanide and mercury in gold refining can lead to pollution of water bodies, soil contamination, and the destruction of ecosystems. These chemicals are highly toxic, and even a small amount released into the environment can have devastating effects on wildlife and human populations. - Health Hazards

The refining process using toxic chemicals poses significant health risks to workers and communities around refining operations. Prolonged exposure to cyanide and mercury can cause severe health problems, including neurological damage, respiratory issues, and in extreme cases, death. - Regulations and Sustainability

Governments and international organizations are increasingly tightening regulations around the use of hazardous chemicals in mining and refining processes. As a result, there is a push for more sustainable, non-toxic alternatives in the gold refining industry.

Alternative Methods of Refining Gold Without Chemicals

Several methods are being developed and tested to refine gold without the use of hazardous chemicals. These methods aim to be more environmentally friendly, cost-effective, and safer for workers.

1. Gravity Concentration

One of the most traditional methods for refining gold without chemicals is gravity concentration. This method relies on the difference in density between gold and other materials. Gold is much denser than other minerals found in ore, so it can be separated through techniques like panning, sluicing, and shaking tables. Gravity concentration is effective for separating gold from its host material but is best suited for smaller-scale operations or recovering gold from alluvial deposits.

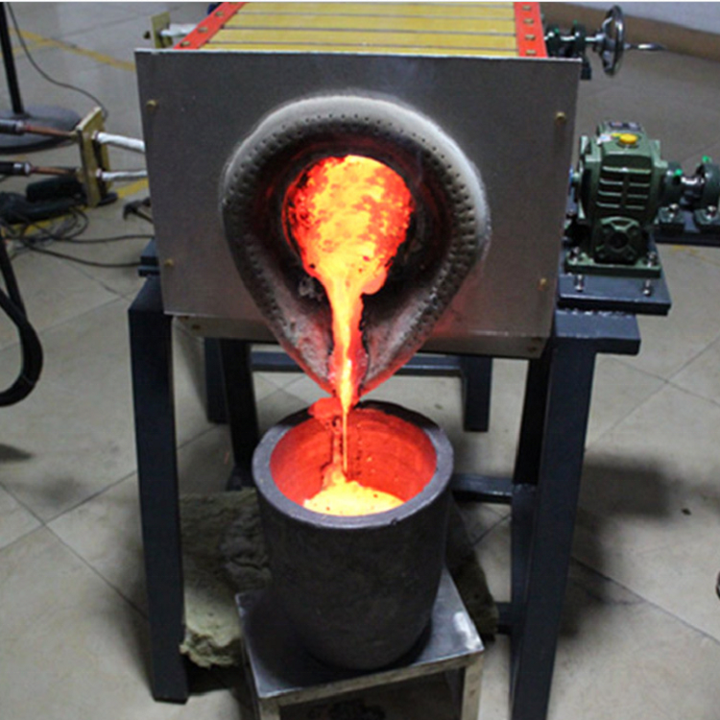

2. Thermal Refining

Thermal refining, or smelting, is another method that can be used to refine gold without the need for toxic chemicals. In this process, gold-bearing materials are heated to a high temperature, causing the impurities to separate and leaving behind pure gold. However, thermal refining is usually limited to larger operations and can require significant energy inputs, making it less ideal for smaller-scale gold recovery.

3. Electrolytic Refining

Electrolytic refining is an efficient method for refining gold without the use of harmful chemicals. This process involves passing an electric current through a solution containing gold ions, which causes the gold to deposit onto a cathode while impurities are left behind. The process is efficient and environmentally friendly, though it requires specific equipment and expertise.

4. Cornstarch Method

A relatively new and promising alternative to chemical-based refining is the cornstarch method, discovered by accident in a laboratory. This method uses a cornstarch-based solution to isolate gold particles from other materials. It has been shown to be as effective as cyanide in separating gold but without the toxic risks associated with traditional methods. While still in the experimental stages, the cornstarch method holds great potential for environmentally safe gold refining.

5. Bioleaching

Bioleaching, also known as biological leaching, is a process that uses microorganisms to extract metals from ore. Certain bacteria can break down minerals and release gold in the process, allowing for the recovery of gold without chemicals. Bioleaching is still being refined for large-scale use but has shown promise as a sustainable and non-toxic alternative for gold refining.

Benefits of Chemical-Free Gold Refining

- Environmental Protection

By avoiding toxic chemicals, eco-friendly refining methods significantly reduce the environmental impact of gold refining. This helps preserve ecosystems, protect water resources, and maintain healthier soils. - Health and Safety

Refining gold without chemicals eliminates the risk of workers and nearby communities being exposed to dangerous substances like cyanide and mercury. This creates a safer working environment and improves overall public health. - Compliance with Regulations

As governments and international bodies continue to implement stricter regulations on the use of hazardous materials in mining and refining, chemical-free methods provide a way to stay compliant while maintaining gold recovery efficiency. - Cost-Effective Alternatives

While some chemical-free refining methods may require investment in specific equipment, over time, they can become more cost-effective by reducing the need for expensive chemicals and the costs associated with managing toxic waste.

Challenges of Chemical-Free Refining

Despite the many advantages, refining gold without chemicals is not without its challenges. Some of these methods may require specialized equipment, and others may not be as efficient for certain types of gold-bearing materials. In addition, research is still ongoing to improve the scalability of some of these processes, particularly for large-scale industrial operations.

Refining gold without chemicals is a promising approach to making the gold refining industry more sustainable, environmentally friendly, and safer for workers and communities. With methods such as gravity concentration, thermal refining, electrolysis, the cornstarch method, and bioleaching, there are multiple alternatives to traditional, chemical-based refining processes. Although some of these methods are still in development or require specific expertise, they offer a glimpse into the future of gold refining—one that is less toxic and more aligned with modern sustainability goals.