Refining Plated Gold

Refining Plated Gold: Techniques and Processes

Refining plated gold is a specialized process that involves removing impurities and recovering the precious metal from items such as jewelry and electronic components. This technique ensures that the gold can be reused or sold at its highest value. FRT Machinery, a leading manufacturer in this field, offers advanced solutions for refining plated gold, making it easier and more efficient than ever before.

Understanding the Basics of Refining Plated Gold

Before diving into the specifics of refining plated gold, it’s essential to understand what it entails. Plated gold refers to items coated with a thin layer of gold over another base metal. When refining these pieces, the goal is to strip away the outer layer of gold while separating it from the base metal. This process requires precision and the right equipment to ensure that the gold is recovered without damage.

FRT Machinery’s Methods for Refining Plated Gold

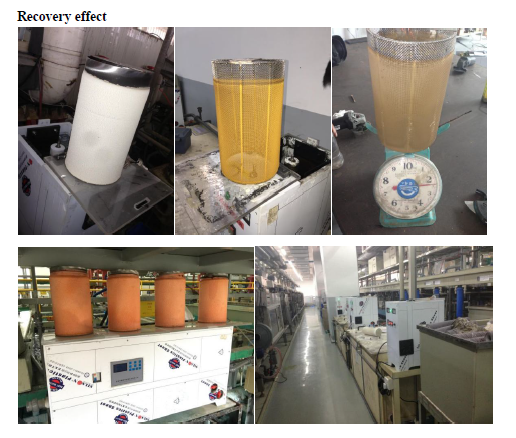

FRT Machinery provides state-of-the-art equipment designed specifically for refining plated gold. These systems incorporate electrolysis and chemical leaching processes that effectively separate gold from the base metals. By using advanced technologies, FRT Machinery ensures high recovery rates and minimal environmental impact.

The Electrolytic Process in Refining Plated Gold

One of the most effective methods used by FRT Machinery is the electrolytic process. This method involves immersing the plated gold item in an electrolyte solution and applying an electric current. The electric current causes the gold to dissolve and collect on the cathode. This process is highly efficient and allows for the recovery of nearly all the gold present in the item.

Chemical Leaching for Refining Plated Gold

Another method employed by FRT Machinery is chemical leaching. This technique uses chemicals like cyanide or thiourea to dissolve the gold from the plated item. After dissolving, the gold can be precipitated out of the solution using zinc dust or other methods. Chemical leaching is particularly useful for items that cannot be processed through electrolysis due to their size or shape.

Environmental Considerations in Refining Plated Gold

When dealing with refining plated gold, environmental concerns are paramount. FRT Machinery designs its equipment with sustainability in mind, ensuring that harmful chemicals are handled safely and that waste products are minimized. Additionally, the company continuously researches and develops new techniques to further reduce the environmental footprint of gold refining processes.

Safety Measures in Refining Plated Gold

Safety is a critical aspect of any industrial process, especially when dealing with chemicals and electrical currents. FRT Machinery implements rigorous safety protocols and provides comprehensive training for operators to handle the equipment safely. All machines are equipped with multiple safety features to protect users and prevent accidents during the refining process.

The Future of Refining Plated Gold with FRT Machinery

As technology advances, so does the efficiency and effectiveness of refining plated gold. FRT Machinery remains at the forefront of innovation, continually improving its machinery to meet the evolving needs of the industry. With a focus on sustainability, safety, and performance, FRT Machinery is setting new standards in gold refining, making it easier for businesses to recover and reuse valuable materials.

By choosing FRT Machinery for your refining needs, you’re not only investing in reliable and advanced equipment but also contributing to a more sustainable future. Whether you’re a small jeweler or a large electronics recycling facility, FRT Machinery has the solutions to help you refine plated gold with confidence and precision.