Refining Scrap Gold Process

Refining Scrap Gold: A Comprehensive Guide to Recovery and Purification

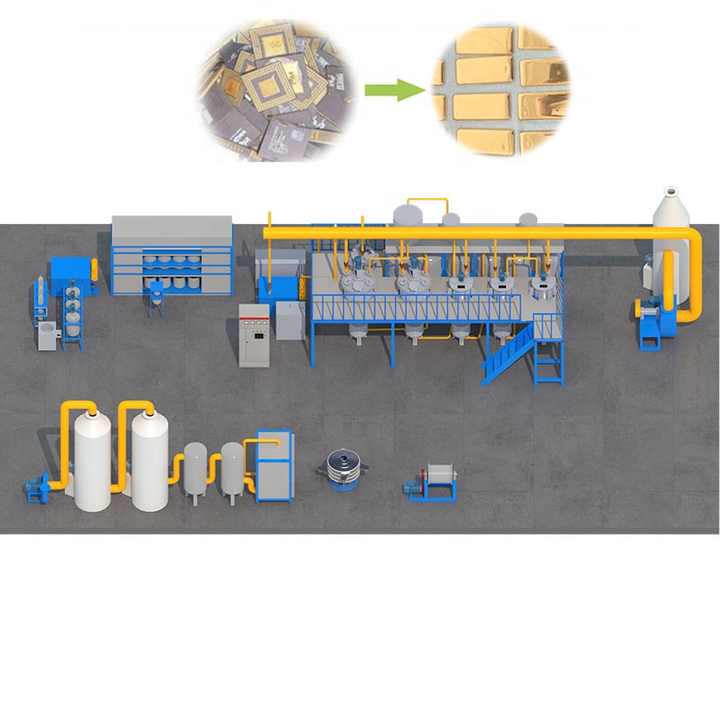

FRT Machinery’s Role in Scrap Gold Refining

Scrap gold refining is a process that transforms discarded or unwanted gold items into pure gold suitable for reuse. This process is essential in recycling valuable metals, reducing the need for new mining operations, and promoting sustainable practices within the jewelry and electronics industries. FRT Machinery, a leading manufacturer of specialized equipment, offers innovative solutions designed specifically for the efficient recovery and purification of scrap gold.

Preparing Scrap Gold for Refining

Before the actual refining process begins, it’s crucial to prepare the scrap gold properly. This involves sorting the materials by karat and removing any non-gold components such as stones, solder, or other alloys. FRT Machinery provides state-of-the-art sorting and separation tools that ensure all non-gold materials are removed efficiently, leaving only pure gold for the next steps in the refining process.

Melting and Alloying in Scrap Gold Refining

Once the scrap gold has been prepared, the next step involves melting it down. This is where FRT Machinery’s high-temperature furnaces come into play, capable of reaching temperatures sufficient to melt gold while ensuring minimal loss due to oxidation. After melting, alloying elements may be added to adjust the gold’s composition if necessary, preparing it for further purification processes.

Electrolytic Refining of Scrap Gold

Electrolytic refining is one of the most effective methods for purifying gold. In this process, impure gold serves as an anode in an electrolyte solution, typically cyanide-based, while pure gold is collected on a cathode. FRT Machinery’s electrolytic refining systems are designed to maximize purity levels, often achieving gold purities greater than 99.95%.

Chemical Refining Techniques for Scrap Gold

Chemical refining techniques involve using acids or other chemicals to dissolve the gold, separating it from impurities. Aqua regia, a mixture of nitric and hydrochloric acids, is commonly used for its ability to dissolve gold completely. FRT Machinery offers specialized tanks and safety equipment necessary for safely handling these corrosive substances during the refining process.

Environmental Considerations in Scrap Gold Refining

While refining scrap gold is beneficial in terms of resource conservation, it also poses environmental challenges. The use of hazardous chemicals can lead to pollution if not managed correctly. FRT Machinery addresses these concerns by providing equipment that minimizes waste and emissions, adhering to strict environmental standards and promoting green practices within the industry.

Final Thoughts on FRT Machinery and Scrap Gold Refining

In conclusion, the process of refining scrap gold is complex yet rewarding, offering both economic benefits and environmental advantages. With the right equipment and expertise, such as those provided by FRT Machinery, businesses can transform old or broken gold items into high-quality, reusable materials. Whether you’re looking to start your own refining operation or upgrade existing facilities, FRT Machinery stands ready to support your efforts towards sustainable gold recycling.