refining silver from scrap

Refining silver from scrap is a valuable process that allows individuals to reclaim and purify silver from various sources such as old jewelry, electronic components, and industrial by-products. This process is both environmentally beneficial and economically advantageous, offering a way to recover precious metals and reduce waste. This guide will provide a detailed overview of refining silver from scrap, including necessary equipment, methods, and safety considerations.

Understanding Silver Refining from Scrap

Refining silver from scrap involves extracting pure silver from items that contain silver but are alloyed with other metals or have been contaminated. The goal is to separate the silver from these impurities to obtain a high-quality, usable product. This process requires a combination of chemical and physical techniques to ensure purity.

Equipment and Materials Needed

1. Safety Gear

Safety is essential when working with chemicals and high temperatures:

- Protective Gloves: To handle chemicals and hot materials safely.

- Safety Goggles: To protect eyes from splashes and fumes.

- Respirator Mask: To avoid inhaling harmful fumes or dust.

- Lab Coat or Apron: To protect skin and clothing from chemicals.

2. Refining Equipment

Essential equipment for refining silver includes:

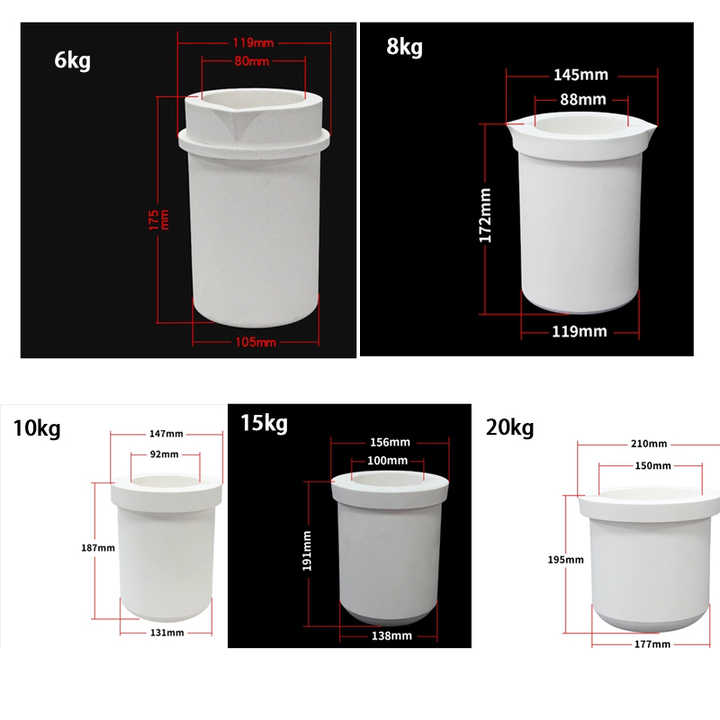

- Crucible: A heat-resistant container for melting the silver scrap.

- Furnace or Torch: Used to heat the crucible to temperatures high enough to melt silver.

- Stirring Rod: For mixing molten silver and flux.

- Tongs: To handle hot crucibles and molds.

- Molds: For pouring and shaping the refined silver into bars or ingots.

3. Chemicals and Fluxes

- Flux: Fluxes such as borax or soda ash help to clean the silver and remove impurities during the melting process.

- Acids: Nitric acid is used to dissolve non-silver metals, while hydrochloric acid may be used to precipitate silver from the solution.

The Refining Process

1. Preparation of Silver Scrap

- Sorting and Cleaning: Collect and clean the silver scrap to remove any dirt, coatings, or non-silver materials. Proper cleaning ensures the efficiency of the refining process.

- Shredding: If necessary, shred larger pieces into smaller fragments to facilitate easier melting and processing.

2. Melting Silver Scrap

- Set Up Furnace: Prepare your furnace or torch to reach temperatures around 962°C (1,764°F), which is sufficient to melt silver.

- Add Flux: Place the silver scrap in the crucible and add flux. The flux helps bind with impurities and forms a slag that can be separated from the molten silver.

- Heat the Crucible: Melt the silver scrap in the furnace, stirring the mixture occasionally with the stirring rod to ensure thorough mixing and purification.

3. Pouring and Solidifying

- Pour the Silver: Carefully pour the molten silver into molds to form bars or ingots. This step should be done with caution to avoid spills and burns.

- Cooling: Allow the silver to cool and solidify in the molds. Once solidified, remove the silver from the molds and inspect it for purity and quality.

4. Acid Treatment (Optional)

For further purification:

- Dissolution: Dissolve the silver in nitric acid to separate it from other metals. This involves adding the silver to a nitric acid solution and allowing it to react.

- Filtration: Filter the solution to remove impurities and non-silver metals.

- Precipitation: Add hydrochloric acid to the solution to precipitate silver chloride, which can then be reduced to pure silver.

Benefits of Refining Silver from Scrap

- Economic Value: Refining scrap silver can be cost-effective compared to purchasing new silver.

- Environmental Impact: Recovering silver from scrap helps reduce waste and environmental impact.

- Educational Experience: The process provides hands-on learning about metallurgy and chemistry.

Considerations and Challenges

- Safety Precautions: Handling chemicals and high temperatures requires strict safety measures.

- Equipment Costs: Initial costs for refining equipment and chemicals can be significant.

- Complexity: The process requires knowledge of metallurgy and chemistry to achieve high purity.

Conclusion

Refining silver from scrap is a practical and rewarding process that allows for the recovery of valuable metal from used or discarded materials. By following the steps outlined—preparing the scrap, melting with flux, pouring into molds, and optionally using acid treatment—you can successfully purify silver at home. Although there are challenges, including safety concerns and equipment costs, the benefits of cost savings, environmental impact, and educational value make refining silver from scrap a worthwhile endeavor.