refining silver ore

The Art of Refining Silver Ore Turning Raw Material into Precious Metal

Silver, a lustrous and versatile metal, has been prized for its beauty and functionality for thousands of years. From ancient coinage to modern electronics, silver plays a vital role in numerous industries. However, before it can be utilized, silver must be extracted and refined from its ore. This article delves into the process of refining silver ore, examining the techniques and steps involved in transforming raw material into a precious metal.

Understanding Silver Ore and Its Composition

Silver ore typically consists of silver embedded within other minerals, such as lead, copper, zinc, or sulfur. The concentration of silver varies widely, ranging from trace amounts to substantial deposits. Before refining can begin, the ore must be extracted from the earth and prepared for processing.

Preparation of Silver Ore

Crushing and Grinding

The first step in refining silver ore is to crush the ore into smaller pieces and grind it into a fine powder. This process increases the surface area of the ore, making it easier for the silver to be separated from the surrounding rock. Crushers and ball mills are commonly used for this purpose.

Extraction Methods

Flotation

One of the most common methods for extracting silver from its ore is flotation. In this process, the powdered ore is mixed with water and various reagents to create a slurry. Air bubbles are introduced into the slurry, and the silver-bearing minerals attach to the bubbles, rising to the surface where they are skimmed off and collected.

Leaching

Another method used for extracting silver is leaching, particularly when dealing with low-grade silver ore. Leaching involves dissolving the silver using a chemical solution, such as cyanide, which selectively dissolves the silver while leaving the other minerals behind. After the leaching process, the solution containing the dissolved silver is treated to recover the metal.

Refining Silver

Once the silver has been extracted from the ore, it is subjected to further refinement to achieve a higher purity level. Several techniques are employed in the refining process:

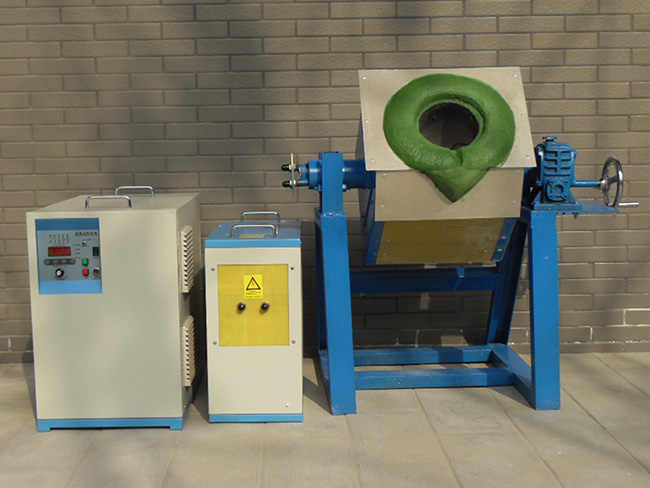

Pyrometallurgy

In pyrometellurgical processes, the silver is heated to high temperatures, causing it to melt and separate from impurities. This method is often used to produce a silver-rich bullion that can then be further refined.

Hydrometallurgy

Hydrometallurgical processes involve the use of aqueous solutions to separate silver from other metals. Electrolysis is a hydrometallurgical technique where an electric current is passed through a solution containing silver ions, causing the silver to deposit on a cathode.

Electrorefining

Electrorefining is a method used to purify the silver obtained from the previous steps. A silver anode is placed in an electrolyte solution containing silver ions. When an electric current is applied, the silver is deposited on a cathode, leaving impurities behind in the solution.

Final Processing and Quality Control

After the refining process, the silver is usually cast into bars or ingots. These are tested for purity using methods such as X-ray fluorescence (XRF) or inductively coupled plasma mass spectrometry (ICP-MS). The purity of the silver is crucial for determining its value and suitability for different applications.

Environmental and Safety Considerations

Refining silver ore involves the use of chemicals and high temperatures, which can present environmental and safety challenges. Proper waste management is essential to prevent contamination of soil and water. Workers must use protective equipment and follow safety protocols to mitigate risks associated with handling the ore and refining processes.

The process of refining silver ore is a testament to human ingenuity and the enduring value of this precious metal. From the initial extraction of the ore to the final refinement of the metal, each step is crucial in transforming raw material into a form that can be used in various applications. By understanding the complexities involved in refining silver ore, we gain insight into the dedication and expertise required to bring this valuable resource to market. As technology advances and environmental awareness grows, the methods used in refining silver ore will continue to evolve, ensuring the sustainable production of this essential metal.