Details

- Home

- refining silver without nitric acid

refining silver without nitric acid

Table of Contents

ToggleRefining Silver Without Nitric Acid An Alternative Approach

Refining silver typically involves the use of nitric acid due to its effectiveness in dissolving silver and separating it from other metals. However, there are alternative methods to refine silver that do not rely on nitric acid. These methods can be useful in various contexts, including situations where nitric acid is not available or suitable. This article explores methods for refining silver without using nitric acid, focusing on different techniques and their advantages.

Alternative Methods for Refining Silver

1. Using Sulfuric Acid

Sulfuric acid can be employed as an alternative to nitric acid in the refining process.

Process Overview

- Preparation: The silver-bearing material is crushed and ground to increase the surface area.

- Dissolving Base Metals: Sulfuric acid is diluted and mixed with the silver-bearing material. It dissolves base metals while leaving the silver relatively unaffected.

- Separation: The solution is filtered to remove solid residues, and silver is precipitated using a reducing agent.

- Conversion: The precipitated silver is washed, dried, melted, and cast into desired forms.

Advantages

- Effective at dissolving base metals.

- Suitable for various types of silver-bearing materials.

2. Using Hydrochloric Acid

Hydrochloric acid can also be used to refine silver, particularly in conjunction with other processes.

Process Overview

- Preparation: Silver material is prepared by crushing and grinding.

- Reaction: Hydrochloric acid is used to dissolve base metals. It forms soluble chloride compounds while leaving silver in a more pure state.

- Precipitation: Silver chloride can be converted back to metallic silver through reduction with a suitable agent.

- Final Processing: The silver is washed, dried, melted, and cast as needed.

Advantages

- Effective for separating silver from base metals.

- Often used in combination with other acids for enhanced refining.

3. Electrolytic Refining

Electrolytic refining is another method that does not rely on nitric acid.

Process Overview

- Preparation: The silver material is set up in an electrolytic cell.

- Electrolytic Process: An electric current is passed through the cell, causing silver to migrate to the cathode while impurities remain at the anode.

- Collection: Pure silver is collected at the cathode, and the process is repeated as necessary.

- Final Steps: The collected silver is melted and cast into bars or other forms.

Advantages

- Produces high-purity silver.

- Does not require strong acids, making it a cleaner process.

4. Fire Assay Method

Fire assay is a traditional method for refining silver and is effective for separating silver from ores and concentrates.

Process Overview

- Preparation: The sample is mixed with flux and heated in a furnace.

- Melting: The flux helps to separate silver from other components by forming a liquid slag that can be removed.

- Separation: Silver is collected in a separate container and allowed to solidify.

- Final Processing: The solidified silver is refined further if necessary.

Advantages

- Proven method for refining silver from ores.

- Effective for large-scale operations.

Benefits of Refining Silver Without Nitric Acid

Reduced Chemical Handling

Using alternative methods can reduce the need for handling nitric acid, which is highly corrosive and requires special safety measures.

Environmental Considerations

Some alternative methods, such as electrolytic refining, produce fewer hazardous byproducts compared to methods that use nitric acid.

Versatility

Different methods offer flexibility in refining various types of silver-bearing materials, depending on the available resources and desired purity.

Challenges and Considerations

Equipment and Expertise

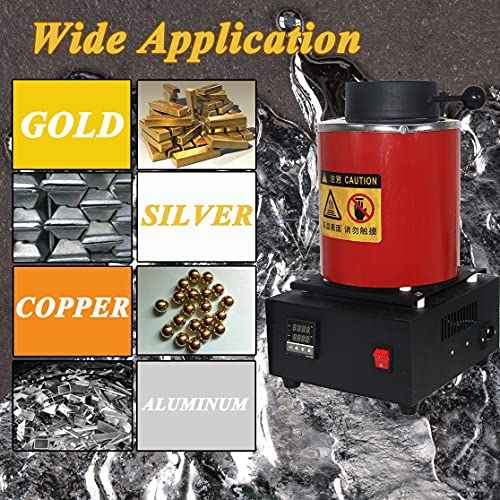

Alternative methods may require specialized equipment and expertise. For example, electrolytic refining requires an electrolytic cell, while fire assay needs a furnace.

Effectiveness

Not all methods are equally effective for all types of silver-bearing materials. The choice of method depends on the specific characteristics of the material being refined.

Safety Precautions

While nitric acid is replaced, alternative acids and methods still require careful handling and safety precautions to avoid accidents and environmental impact.

Refining silver without nitric acid involves various alternative methods, each with its advantages and challenges. Sulfuric acid, hydrochloric acid, electrolytic refining, and fire assay offer viable options for purifying silver and separating it from base metals. Understanding these methods allows for flexibility in refining processes, catering to different needs and circumstances. With proper equipment, expertise, and safety measures, these alternative methods can effectively produce high-quality silver.